Mitsubishi Montero (1998+). Manual - part 96

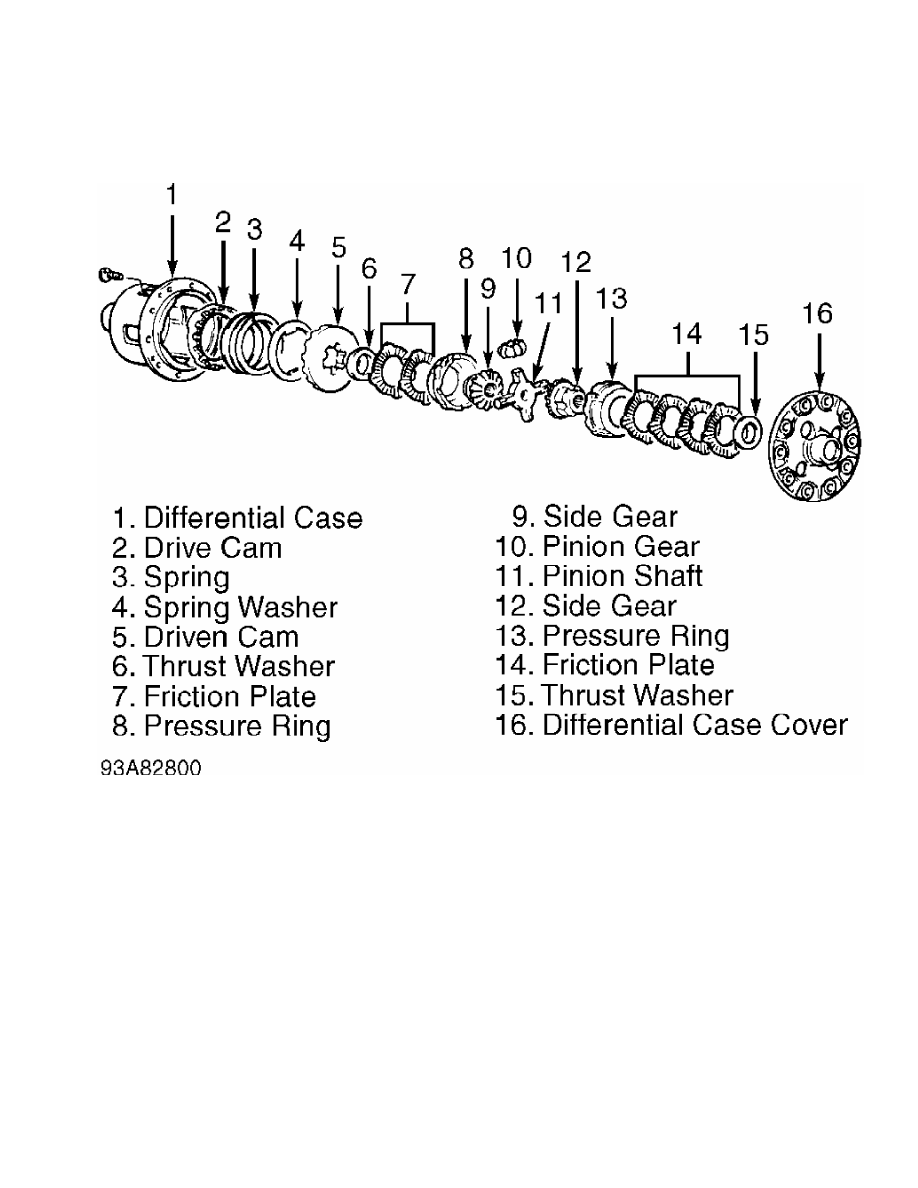

Fig. 12: Exploded View Of Locking Differential

Courtesy of Mitsubishi Motor Sales of America.

Reassembly

1) Arrange friction plates and discs of each side of

differential. Measure each assembly thickness. Assembled discs and

plates should not exceed a difference of .002" (.05 mm). Replace discs

or plates as needed.

2) Assemble one spring plate and one spring disc on each

side. Measure assembly thickness. Assemble disc and plates to obtain

minimum difference in thickness between each assembly.

3) Assemble clutch assemblies, pressure rings, pinion gears,

side gears and pinion shaft. Measure overall width of assembly plus

spring plates and spring discs (dimension "C"). See Fig. 13.

4) Determine depth of differential case (dimension "D"). On

2.4L, dimension "D" = "E" + "F" - "G"; on 3.0L, dimension "D" = "E" +

"H"

See Fig. 14. Subtract "C" from "D" to determine spring plate-

to-case clearance. Adjust spring disc thickness to obtain proper

spring plate-to-case clearance. Correct clearance is .0024-.0079" (.

060-.200 mm).