Mitsubishi Montero (1991+). Manual - part 320

the iron core here.

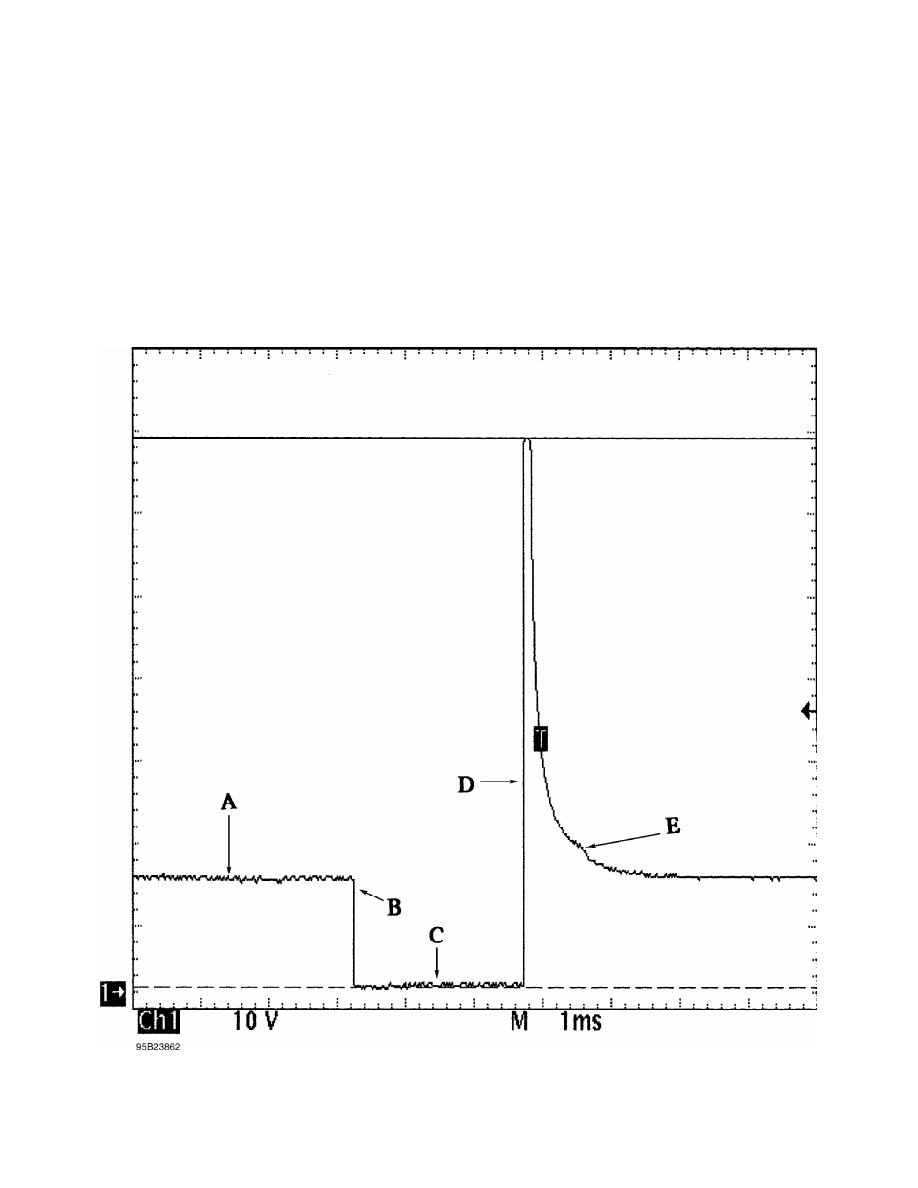

This pintle hump at Point "E" should occur near the end of

the downward slope, and not afterwards. If it does occur after the

slope has ended and the voltage has stabilized, it is because the

pintle is slightly sticking because of a faulty injector

If you see more than one hump it is because of a distorted

pintle or seat. This faulty condition is known as "pintle float".

It is important to realize that it takes a good digital

storage oscilloscope or analog lab scope to see this pintle hump

clearly. Unfortunately, it cannot always be seen.

Fig. 2: Identifying Voltage Controlled Type Injector Pattern

INTERPRETING A CURRENT CONTROLLED PATTERN

NOTE: Current controlled drivers are also known as "Peak and Hold"