Mitsubishi Montero (1991+). Manual - part 213

not present, check circuit between relay and battery, including

fusible link No. 1.

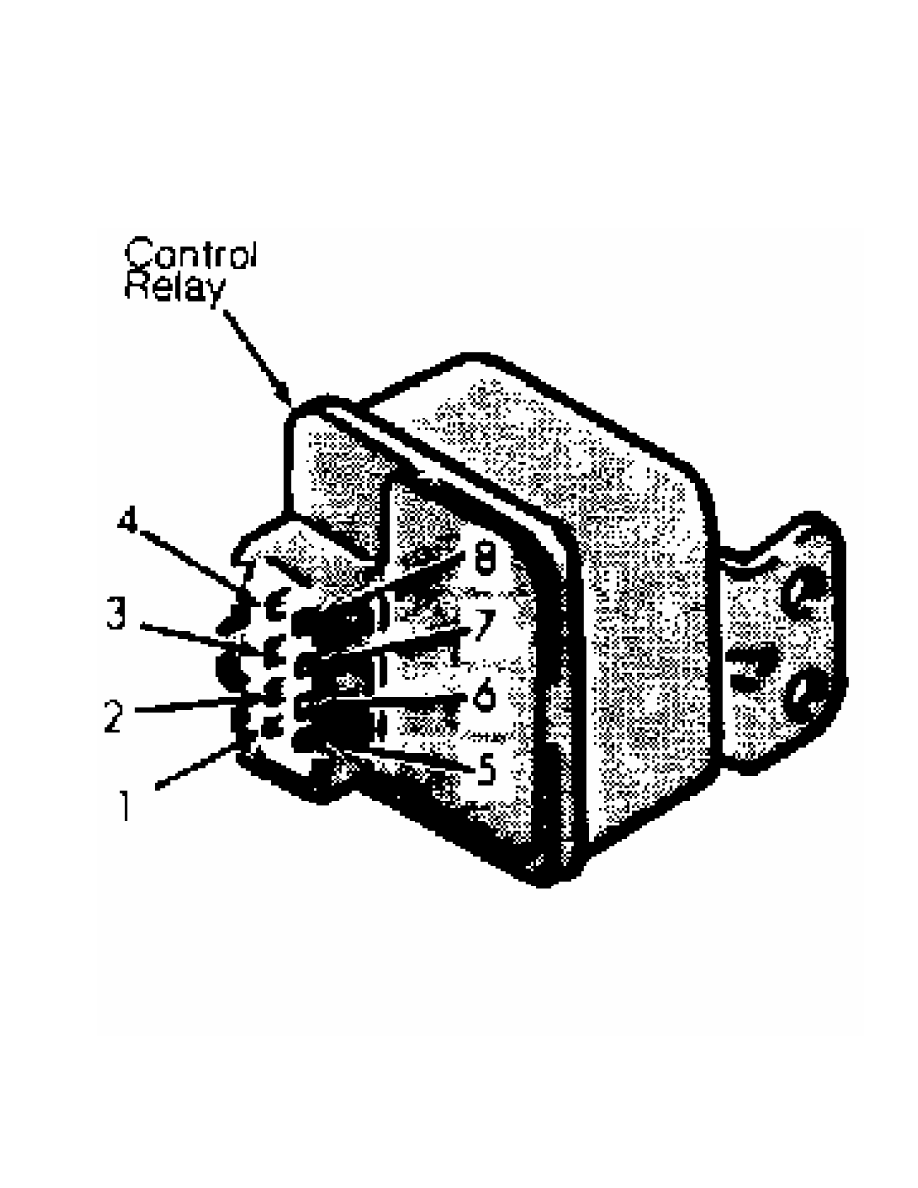

Fig. 10: MPI Control Relay Connector Term. ID (8 Pin)

Courtesy of Mitsubishi Motor Sales of America.

2) Disconnect wiring harness connector at relay. Remove

relay. Check continuity between terminals No. 1 and 4, terminals No. 2

and 4 and terminals No. 3 and 4. If there is no continuity, go to next