Mitsubishi Montero (1991+). Manual - part 117

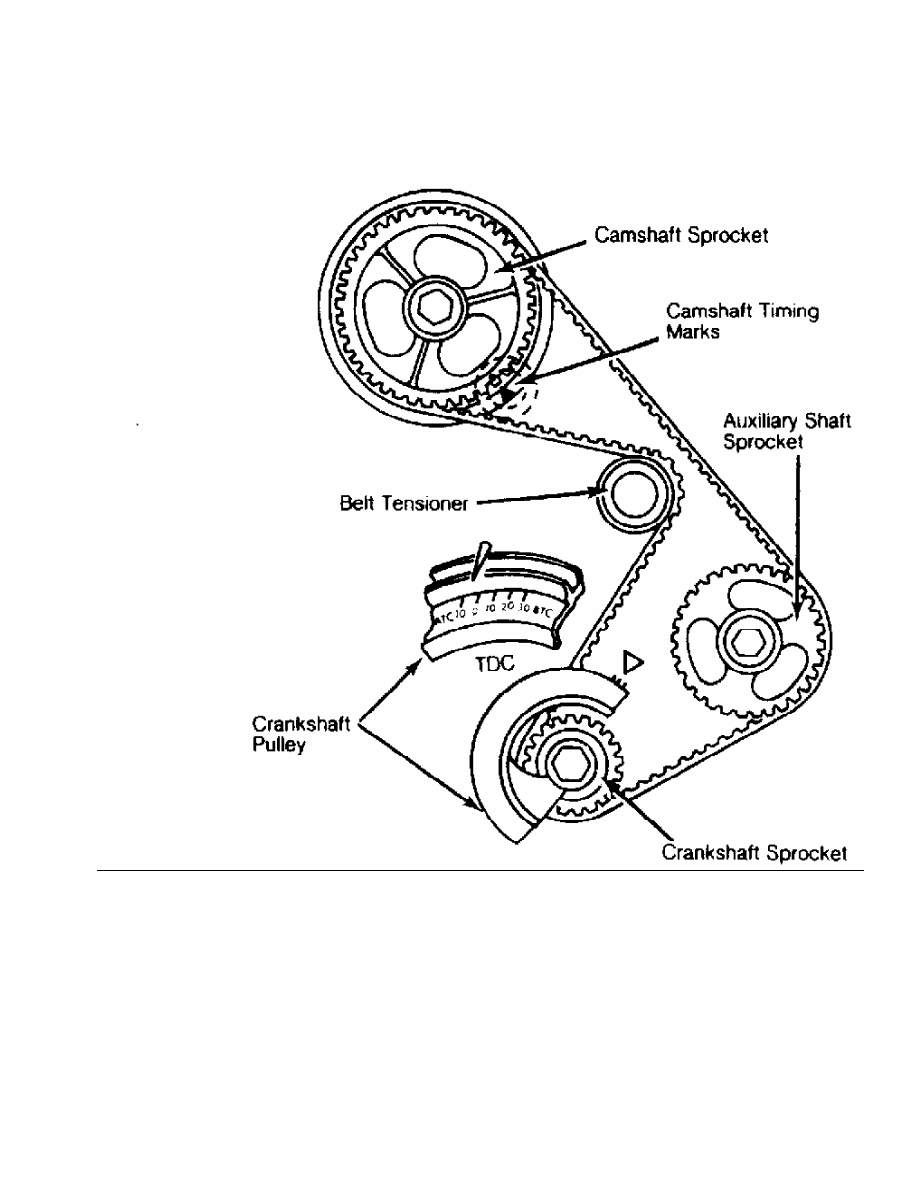

Fig. 25: Timing Belt Sprocket Alignment - Typical

This Graphic For General Information Only

TENSION ADJUSTMENTS

If guide rails are used with spring loaded tensioners,

ensure at least half of original rail thickness remains. Spring

loaded tensioner should be inspected for damage.

Ensure all timing marks are aligned. Adjust belt tension

using manufacturer’s recommendations. Belt tension may require

checking using tension gauge. See Fig. 26.