Mitsubishi Montero (1991+). Manual - part 13

immediately before connections are made. This will keep entry of air

and moisture to a minimum.

CONNECTING LINES AND FITTINGS

A new gasket or "O" ring should be used in all instances when

connecting lines or fittings. Dip "O" ring in new refrigerant oil and

ensure it is not twisted during installation. Always use 2 wrenches to

prevent damage to lines and fittings.

PLACING SYSTEM IN OPERATION

After component service or replacement has been completed and

all connections have been made, evacuate system thoroughly with a

vacuum pump. Charge system with proper amount of refrigerant and

perform a leak test. See REFRIGERANT OIL & R-12 SPECIFICATIONS chart

in this section for system capacities. Be sure to check all fittings

that have been opened. After system has been leak tested, make a

system performance check.

NOTE: Air conditioning systems will not normally need addition of

refrigerant oil unless definite oil loss has occurred due to

ruptured lines, leaking compressor seals, compressor

overhaul or component replacement.

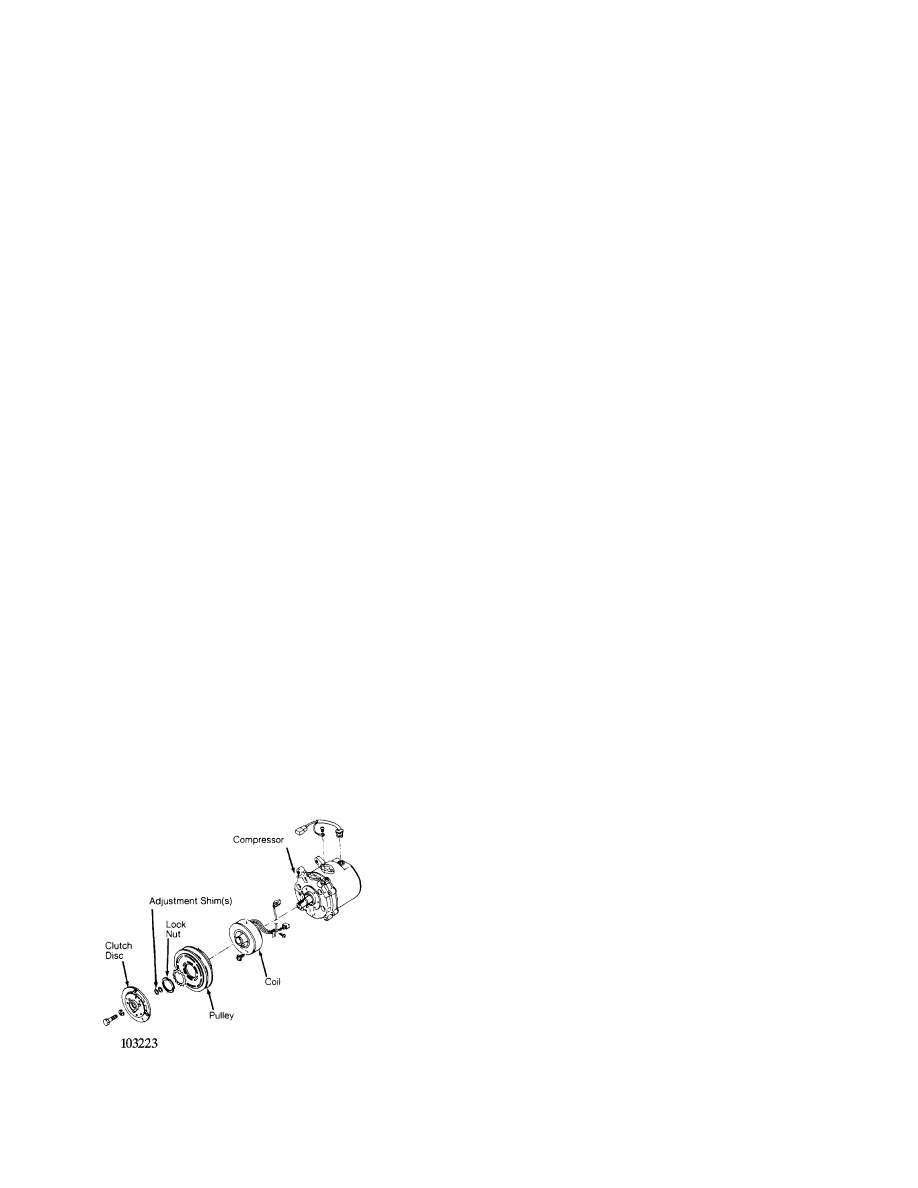

ATSUGI ROTARY VANE CLUTCH R & I

Removal

When replacing compressor clutch, be careful not to scratch

shaft or bend pulley. When removing center bolt, hold clutch disc with

Clutch Holder (KV99231010). Using Hub Puller (KV998VR001 &

KV99231010), remove clutch disc. When removing pulley, remove lock nut

with Hub Socket (KV99235160).

Installation

Wipe oil off clutch surface. Adjust disc pulley clearance to

.012-.024" (.3-.6 mm). Tighten center bolt to 80-104 INCH lbs. (9.1-

11.8 N.m). Tighten clutch lock nut to 22-29 ft. lbs. (29-39 N.m). See

Fig. 1.

Fig. 1: Atsugi Rotary Vane Compressor

Courtesy of Nissan Motor Co., U.S.A.

BOSCH 6-CYL CLUTCH R & I