Mitsubishi Galant (2004+). Manual - part 979

MULTIPORT FUEL INJECTION (MFI) DIAGNOSIS

TSB Revision

MULTIPORT FUEL INJECTION (MFI) <2.4L ENGINE>

13A-733

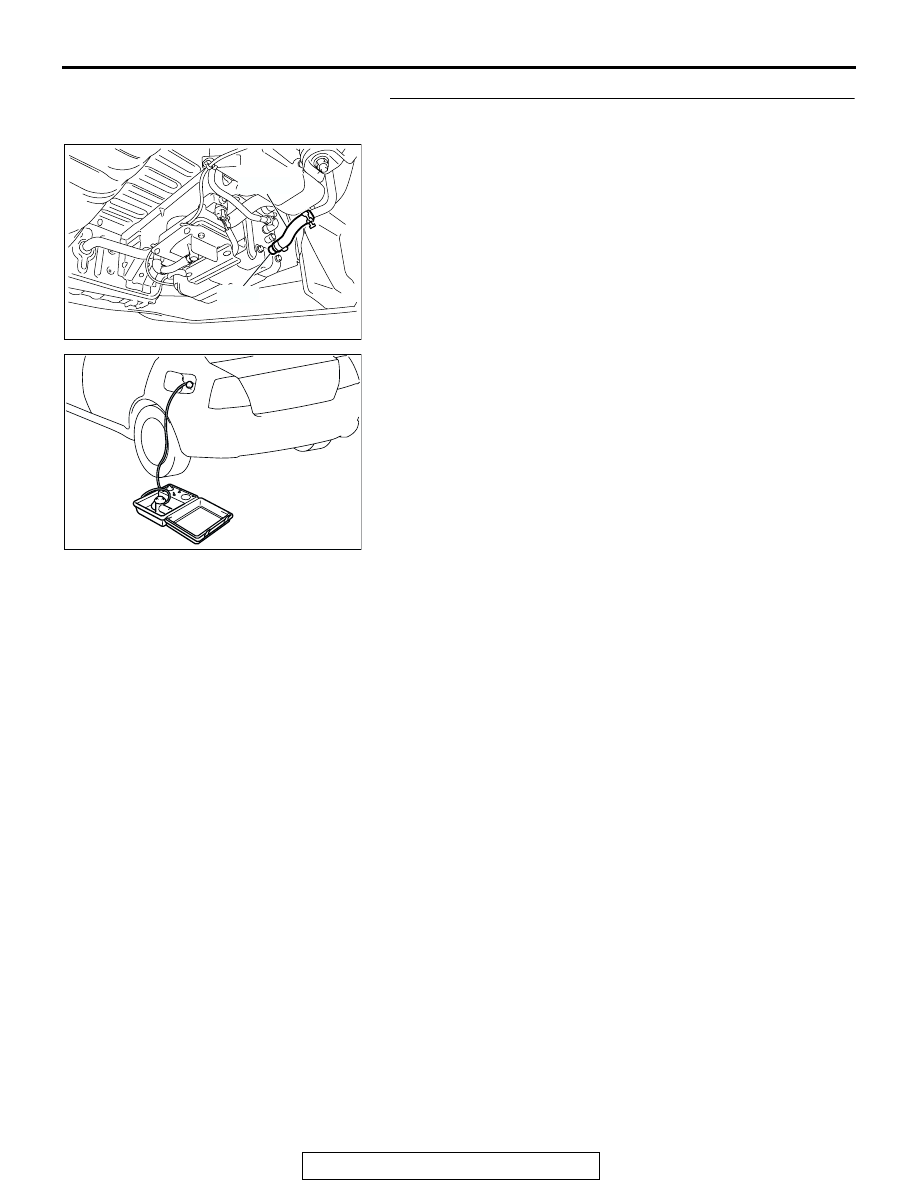

STEP 7. Pressure test the evaporative emission system

lines from hoses I to N.

(1) Disconnect hose I from the evaporative emission canister,

and plug hose I securely.

(2) Confirm that the evaporative emission system pressure

pump (Miller number 6872A) is operating properly. Perform

the self-test as described in the pump manufacturer’s

instructions.

(3) Remove the fuel cap.

(4) Connect the evaporative emission system pressure pump

(Miller number 6872A) to the fuel tank filler tube by using

fuel tank adapter (MLR-8382).

(5) Pressure test the system to determine whether any leaks

are present.

NOTE: The "Pressure test" in this procedure refers to the

I/M240 Simulation Test. The eight steps of this test are

described in the manufacturer’s instructions for the evapo-

rative emission system pressure pump, Miller number

6872A.

(6) Remove the evaporative emission system pressure pump

(Miller number 6872A) and the fuel tank adapter

(MLR-8382), and reinstall the fuel cap.

(7) Connect hose I to the evaporative emission canister.

Q: Is the evaporative emission system line free of leaks?

YES : Go to Step 13.

NO : Go to Step 8.

AC306778

AB

HOSE I

PLUG

AC306661