Mitsubishi Galant (2004+). Manual - part 712

TRANSAXLE ASSEMBLY

TSB Revision

AUTOMATIC TRANSAXLE

23A-399

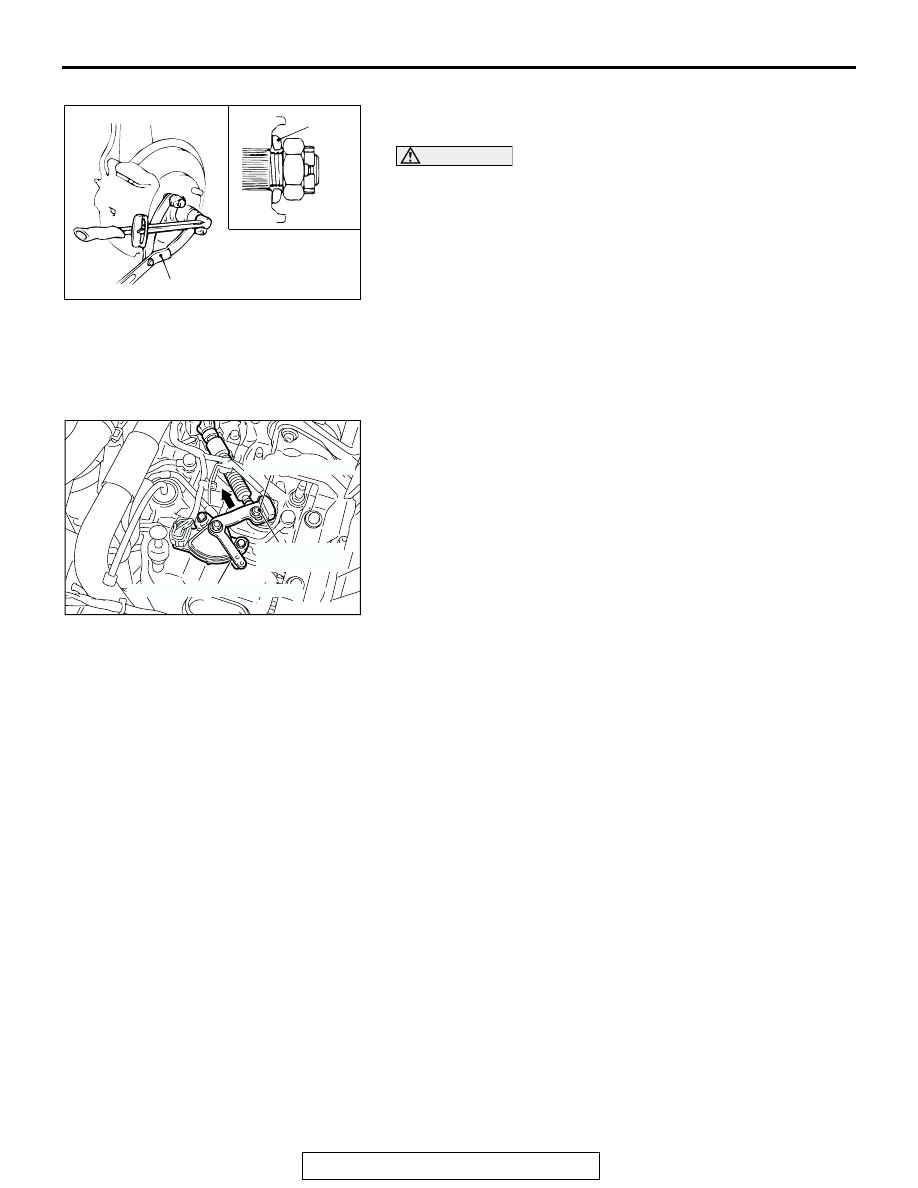

>>D<< DRIVE SHAFT NUT INSTALLATION

1. Be sure to install the drive shaft washer in the specified

direction.

CAUTION

Before securely tightening the drive shaft nuts, make sure

there is no load on the wheel bearings. Otherwise the

wheel bearing will be damaged.

2. Using special tool MB990767, tighten the drive shaft nut to

the specified torque.

Tightening torque: 226

± 29 N⋅m (167 ± 21 ft-lb)

.

>>E<< ADJUSTING NUT/TRANSAXLE CONTROL CABLE

(TRANSAXLE SIDE) INSTALLATION

1. Place the selector lever and manual control lever in the “N”

position.

2. Place the cable stud into the manual control lever slot and

install the nut loosely. Gently push the transaxle control

cable into the manual control lever slot until the cable is taut.

Tighten the nut to the specified torque.

Tightening torque: 12

± 2 N⋅m (107 ± 17 in-lb)

AC210244AB

MB990767

WASHER

AC305532

12 ± 2 N·m

107 ± 17 in-lb

MANUAL CONTROL LEVER

ADJUSTING NUT

AE