Mitsubishi Galant (2004+). Manual - part 688

AUTOMATIC TRANSAXLE DIAGNOSIS

TSB Revision

AUTOMATIC TRANSAXLE

23A-303

INSPECTION PROCEDURE 10: Early or Late Shifting in All Gears

.

COMMENT

If all shift points are early or late while driving, the

cause is probably a malfunction of the output shaft

speed sensor, TP sensor or a solenoid valve.

.

TROUBLESHOOTING HINTS (The most likely

causes for this condition:)

• Malfunction of the output shaft speed sensor

• Malfunction of the TP sensor

• Malfunction of each solenoid valve

• Abnormal line pressure

• Malfunction of the valve body

• Malfunction of the PCM

DIAGNOSIS

Required Special Tool:

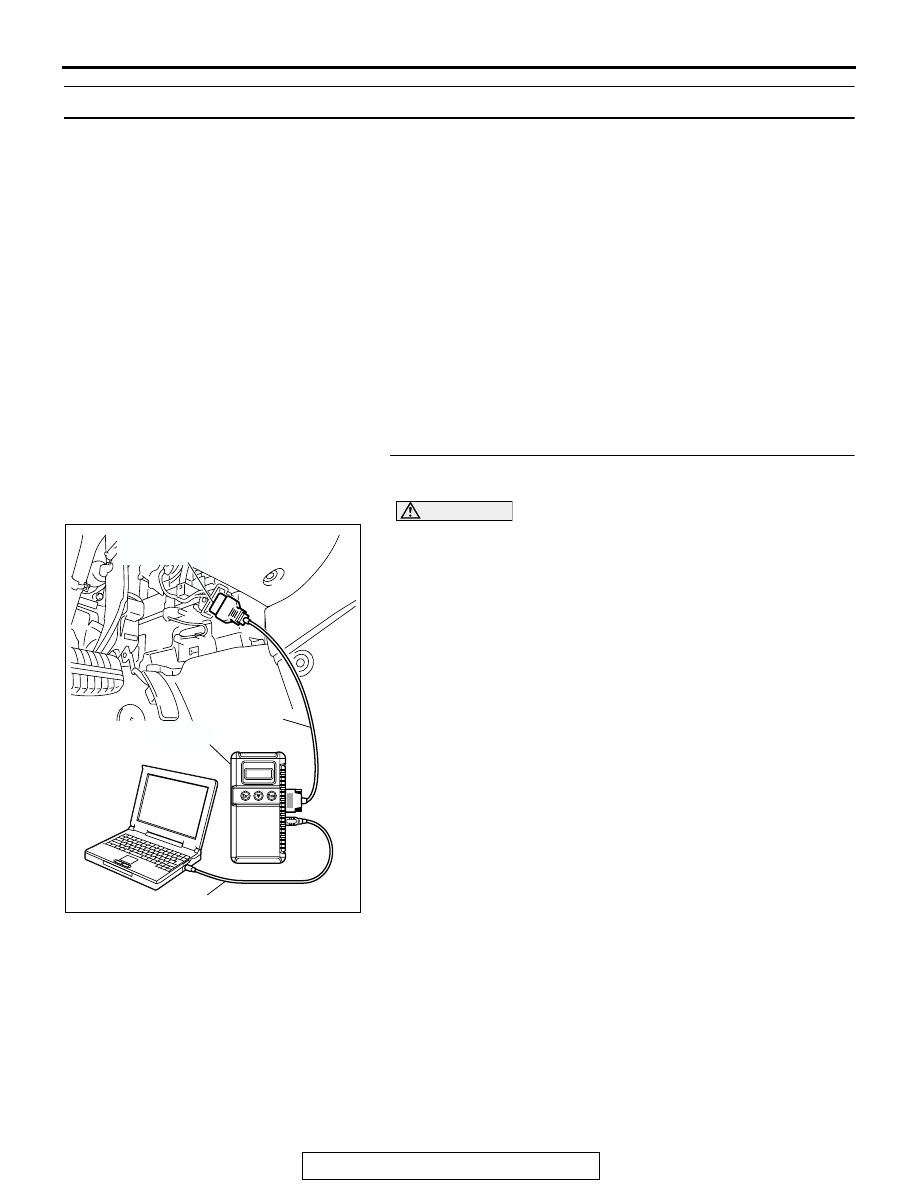

• MB991958: Scan Tool (MUT-III Sub Assembly)

• MB991824: V.C.I.

• MB991827: MUT-III USB Cable

• MB991910: MUT-III Main Harness A

STEP 1. Using scan tool MB991958, check data list item 23:

Output Shaft Speed Sensor.

CAUTION

To prevent damage to scan tool MB991958, always turn the

ignition switch to the "LOCK" (OFF) position before con-

necting or disconnecting scan tool MB991958.

(1) Connect scan tool MB991958 to the data link connector.

(2) Start the engine.

(3) Set scan tool MB991958 to the data reading mode.

• Item 23: Output Shaft Speed Sensor.

• When driving at constant speed of 50km/h (31mph),

the display should be "1,400

− 1,700 r/min" (Gear

range: 3rd gear).

(4) Turn the ignition switch to the "LOCK" (OFF) position.

Q: Is the sensor operating properly?

YES : Go to Step 2.

NO : Refer to

, DTC 23: Output shaft speed

sensor system.

AC305412

AB

MB991910

DATA LINK

CONNECTOR

MB991824

MB991827