Mitsubishi Galant (2004+). Manual - part 634

AUTOMATIC TRANSAXLE DIAGNOSIS

TSB Revision

AUTOMATIC TRANSAXLE

23A-87

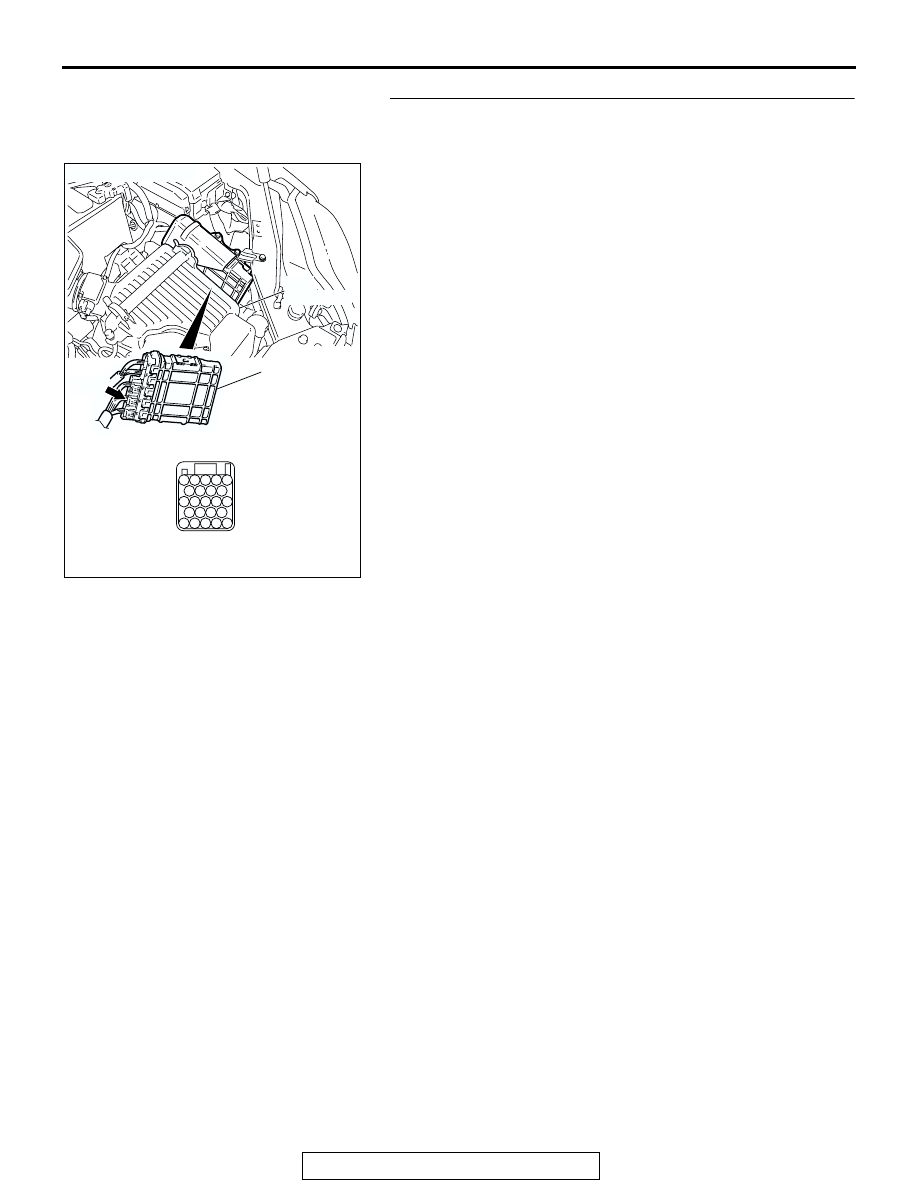

STEP 15. Check PCM connector B-22 for loose, corroded

or damaged terminals, or terminals pushed back in the

connector.

Q: Are the connector and terminals in good condition?

YES : Replace the PCM.

NO : Repair or replace the damaged components. Refer to

GROUP 00E, Harness Connector Inspection

AC306248AE

B-22

(B)

CONNECTOR: B-22

PCM

AIR

CLEANER

JAE

94

98

107

103

112

91

100

109

101102

106

110

105

111

97

92

96

93

104

113

108

95

99