Mitsubishi Galant (2004+). Manual - part 607

PISTON AND CONNECTING ROD

TSB Revision

ENGINE OVERHAUL <3.8L ENGINE>

11D-45

3. Check the body clearance.

Standard value: 0.10

− 0.18 mm (0.004 − 0.007 inch)

Limit: 0.35 mm (0.013 inch)

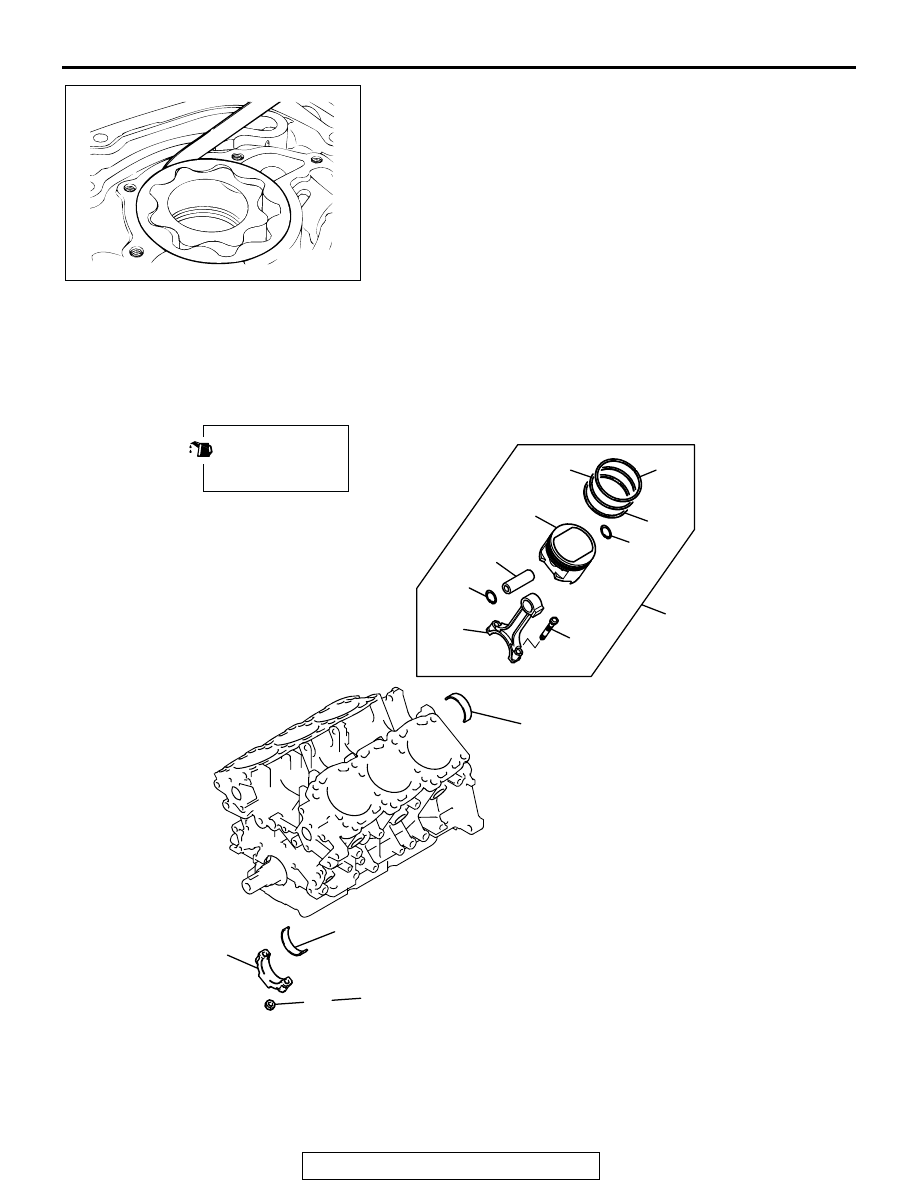

PISTON AND CONNECTING ROD

REMOVAL AND INSTALLATION

M1113008400636

AKX00745

AK201085

1

2

3

4

5

6

7

8

9

10

11

12

13

14

27 ± 2 N·m

20 ± 1 ft-lb

+ 90˚ TO 94˚

AC

APPLY ENGINE OIL

TO ALL MOVING

PARTS BEFORE

INSTALLATION.

REMOVAL STEPS

>>G<<

1. CONNECTING ROD CAP NUT

<<A>> >>F<<

2. CONNECTING ROD CAP

>>D<<

3. CONNECTING ROD BEARING,

LOWER

>>E<<

4. PISTON AND CONNECTING ROD

ASSEMBLY

>>D<<

5. CONNECTING ROD BEARING,

UPPER

REMOVAL STEPS (Continued)