Mitsubishi Galant (2004+). Manual - part 594

CRANKSHAFT AND CYLINDER BLOCK

TSB Revision

ENGINE OVERHAUL <2.4L ENGINE>

11B-65

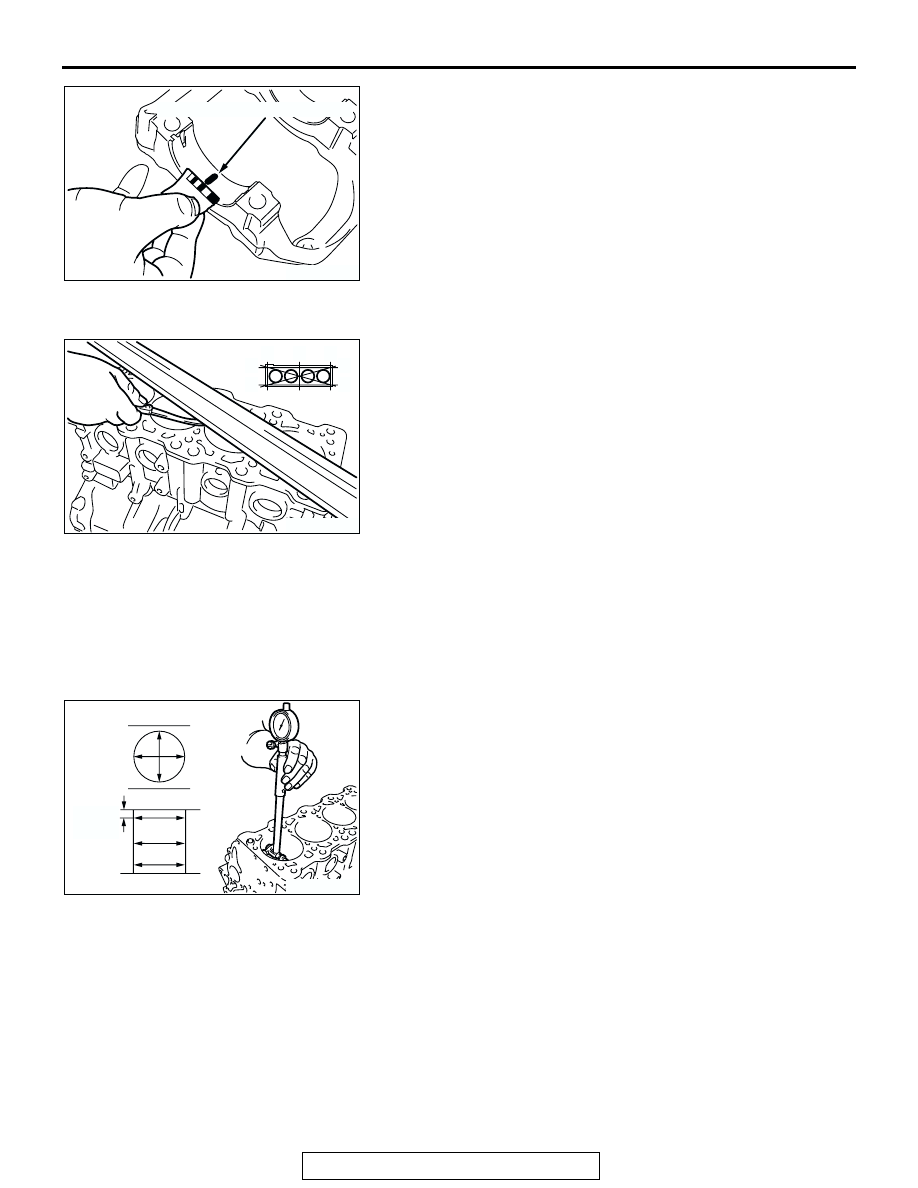

6. Measure the width of the plastic gauging material at its

widest part by using a scale printed on the plastic gauging

material package.

Standard value: 0.02

− 0.04 mm (0.0008 − 0.0015 inch)

Limit: 0.1 mm (0.003 inch)

.

CYLINDER BLOCK

1. Visually check for scratches, rust, and corrosion.

Use also a flaw detecting agent for the check. If defects are

evident, correct or replace.

2. Using a straightedge and feeler gauge, check the block top

surface for warpage. Make sure that the surface is free from

gasket chips and other foreign matter.

Standard value: 0.05 mm (0.0020 inch)

Limit: 0.1 mm (0.003 inch)

3. If the distortion is excessive, correct within the allowable

limit or replace.

Grinding limit: 0.2 mm (0.007 inch)

*Includes/combined with cylinder head grinding

Cylinder block height (when new):

290 mm (11.4 inches)

4. Check cylinder walls for scratches and seizure. If defects

are evident, replace or bore to oversize and replace pistons

and piston rings.

5. Using a cylinder gauge, measure the cylinder bore and

cylindrically. If worn badly, correct the cylinder to an oversize

and replace the piston and piston rings. Measure at the

points shown in the illustration.

Standard value:

Cylinder inner diameter 87.0 mm (3.43 inches)

Cylindrically 0.01 mm (0.0003 inch) or less

.

AK300204

PLASTIC GAUGING MATERIAL

AC

AK300205

A

B

C

D

E

F

G

AK300206

12mm

(0.47 in)

AC

A

B

CENTER

BOTTOM