Mitsubishi Galant (2004+). Manual - part 551

DRIVE SHAFT ASSEMBLY

TSB Revision

FRONT AXLE

26-23

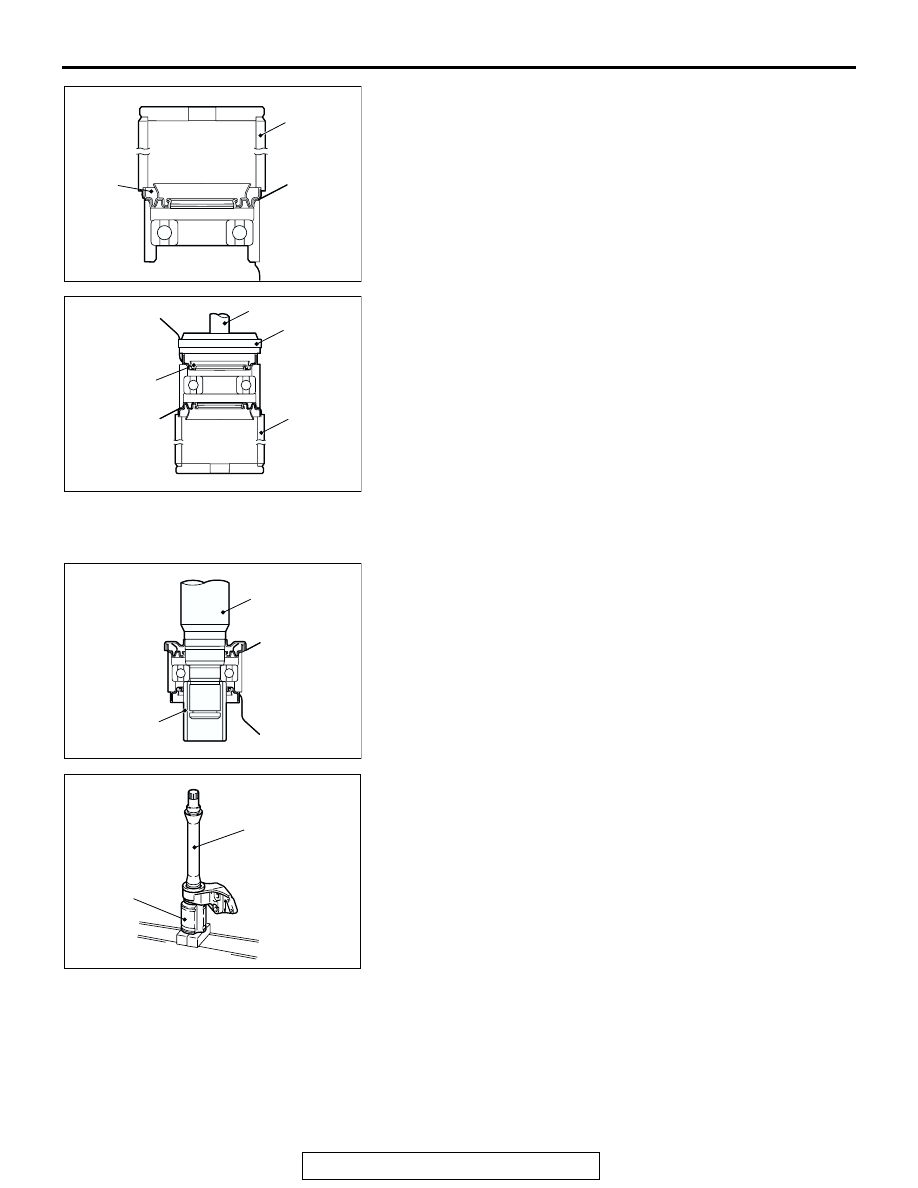

2. Use special tools MB990890, MB990938, and MB990934 to

press the dust seals into the center bearing bracket until

they are flush with each other.

3. Apply repair kit grease to the lip of each dust seal.

.

>>E<<INNER SHAFT <3.8L-RH> INSTALLATION

1. Use special tool MB991172 to hold the center bearing inner

race, and then press-in the inner shaft.

2. Apply repair kit grease to the inner shaft spline, then press fit

it into the PTJ case.

NOTE: When press-fitting the inner shaft into the PTJ case,

apply a thin coat of repair kit grease to the dust seal outer lip

part and the outside edge of the PTJ axial part.

.

AC101696

MB990890

DUST

SEAL

INNER

AC

AC101697

MB990938

MB990934

MB990890

DUST SEAL

OUTER

AC

AC101698

MB991172

INNER SHAFT

AC

AC205847

AC305786

PTJ CASE

INNER SHAFT

AB