Mitsubishi Galant (2004+). Manual - part 167

CHARGING SYSTEM

TSB Revision

ENGINE ELECTRICAL

16-9

10.With the engine running at 2,500 r/min, turn the

headlights and other lights on and off to adjust the

generator load so that the value displayed on the

ammeter is slightly above 30 A.

Read the voltmeter. Voltage reading at or below

limit value means voltage drop between generator

and battery is OK.

Limit value: maximum 0.3 V

NOTE: When the generator output is high and the

value displayed on the ammeter does not

decrease to 30 A, set the value to 40 A. Read the

value displayed on the voltmeter at this time.

In this case the limit value becomes maximum 0.4

V.

Adjust the engine speed by gradually decreasing

it until the value displayed on the ammeter is 30

A. Take a reading of the value displayed on the

voltmeter at this time.

11.If the value displayed on the voltmeter is above

the limit value, there is probably a malfunction in

the generator output wire. Check the wiring

between the generator "B" terminal and the

positive battery terminal (including fusible link).

If a terminal is not sufficiently tight or if the

harness has become discolored due to

overheating, repair and then test again.

12.After the test, run the engine at idle.

13.Turn off all lights and turn the ignition switch to the

"LOCK" (OFF) position.

NOTE: Vehicles for Canada, the headlight, tail-

light, etc. remain lit even when the lighting switch

is in "OFF" position.

14.Disconnect the engine tachometer or scan tool

MB991958.

15.Disconnect the negative battery cable.

16.Disconnect the ammeter and voltmeter.

17.Connect the negative battery cable.

18.Run the engine for 10 minutes at an idle.

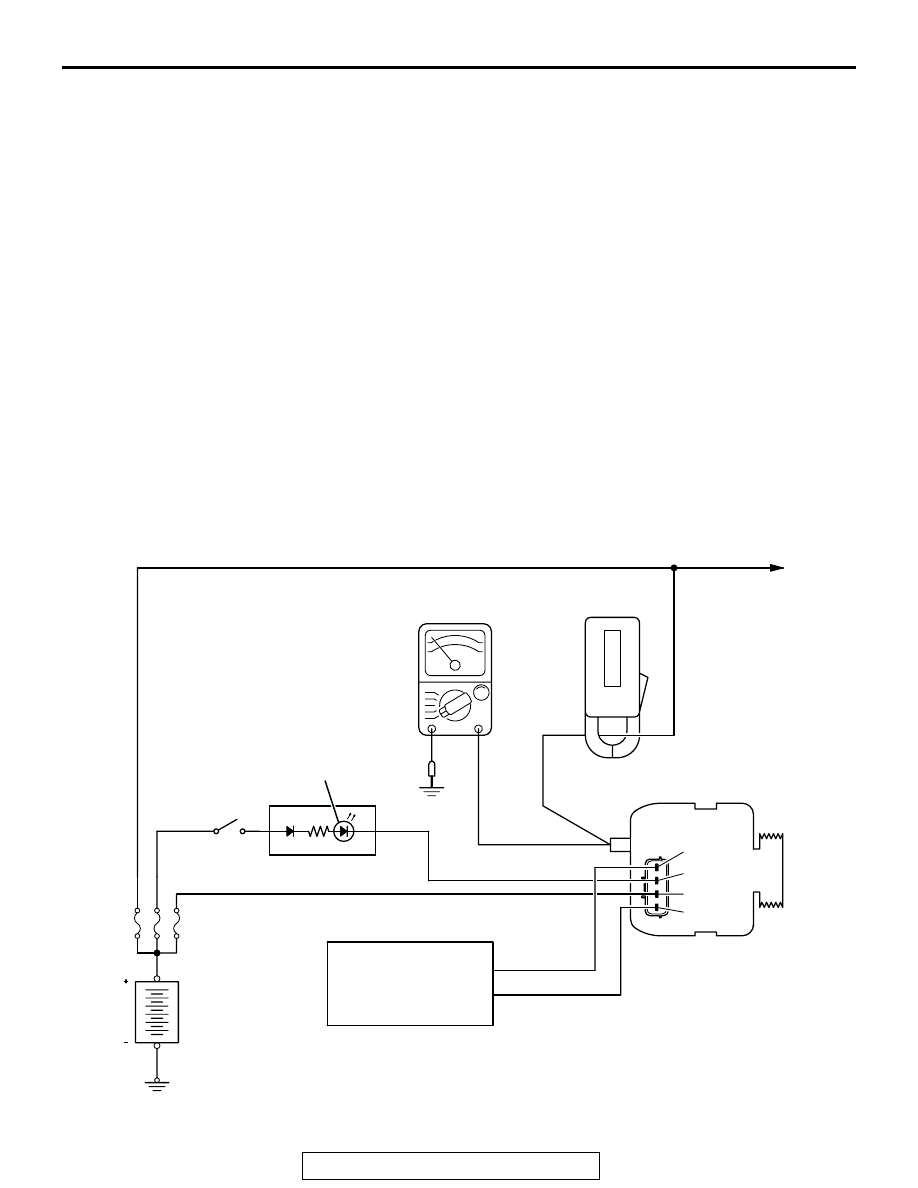

OUTPUT CURRENT TEST

M1161001000391

AK303633

GENERATOR

AMMETER

(CLAMP-TYPE)

VOLTMETER

IGNITION

SWITCH

LOAD

B

FR

L

S

G

GENERATOR

MALFUNCTION

LIGHT

COMBINATION METER

BATTERY

+

AB

–

PCM