Content .. 1638 1639 1640 1641 ..

Mitsubishi Galant (2004+). Manual - part 1640

TRANSAXLE

TSB Revision

AUTOMATIC TRANSAXLE OVERHAUL

23B-49

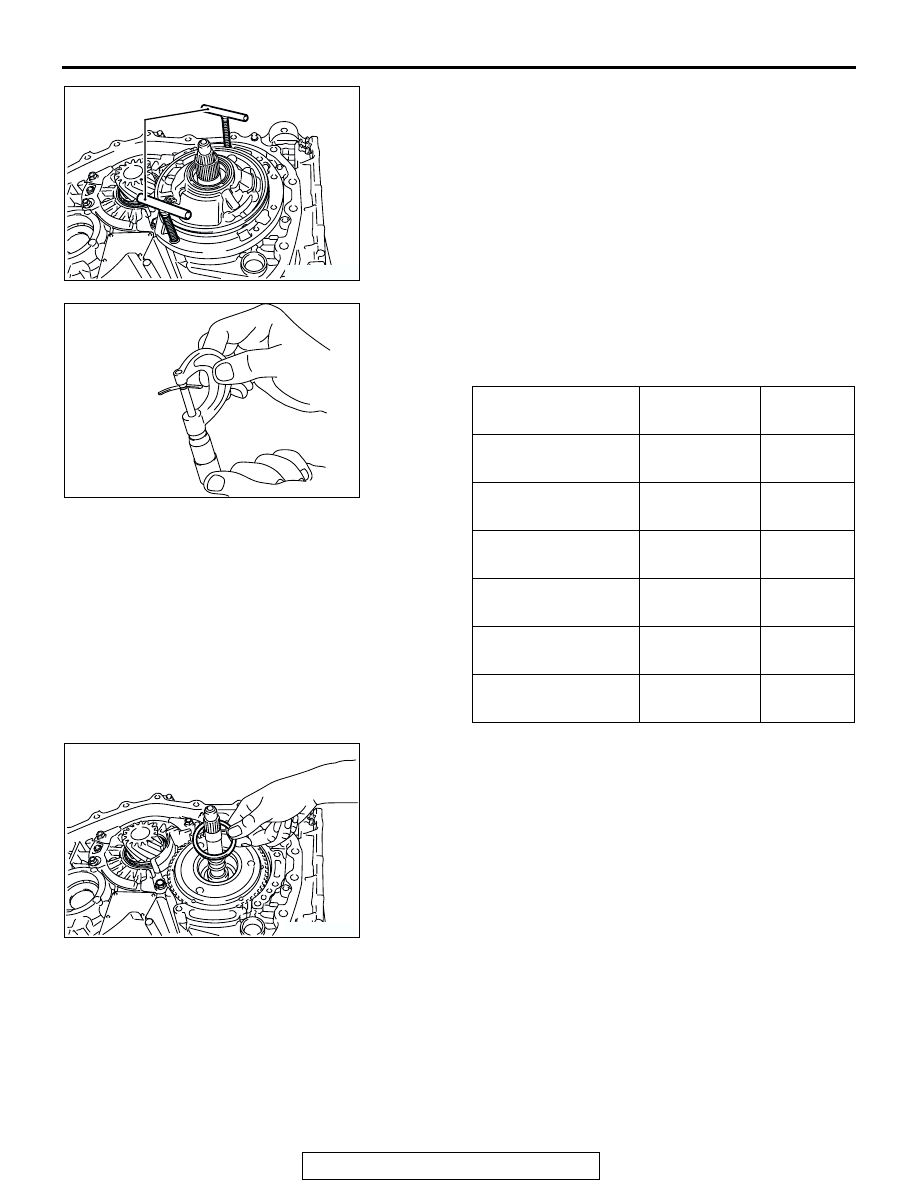

63.Using special tools MD998333, remove the oil pump and

the crushed solders.

64.Use a micrometer to measure the thickness of the crushed

solder beads and record the measured value.

65.Select a thrust washer number 1 whose thickness

corresponds to the measured value from table below.

66.Install thrust washer number 1 that was selected in step 64

on the underdrive clutch retainer.

AK300236AD

MD998333

MEASUREMENT

VALUE mm (in)

THICKNESS

mm (in)

ID

SYMBOL

2.25

− 2.45

(0.089

− 0.096)

1.8 (0.071)

18

2.45

− 2.65

(0.096

− 0.104)

2.0 (0.079)

20

2.65

− 2.85

(0.104

− 0.112)

2.2 (0.087)

22

2.85

− 3.05

(0.112

− 0.120)

2.4 (0.094)

24

3.05

− 3.25

(0.120

− 0.128)

2.6 (0.102)

26

3.25

− 3.45

(0.128

− 0.136)

2.8 (0.110)

28

AK301249

AK300237