Mitsubishi Galant (2004+). Manual - part 143

CYLINDER HEAD GASKET

TSB Revision

ENGINE MECHANICAL <2.4L ENGINE>

11A-45

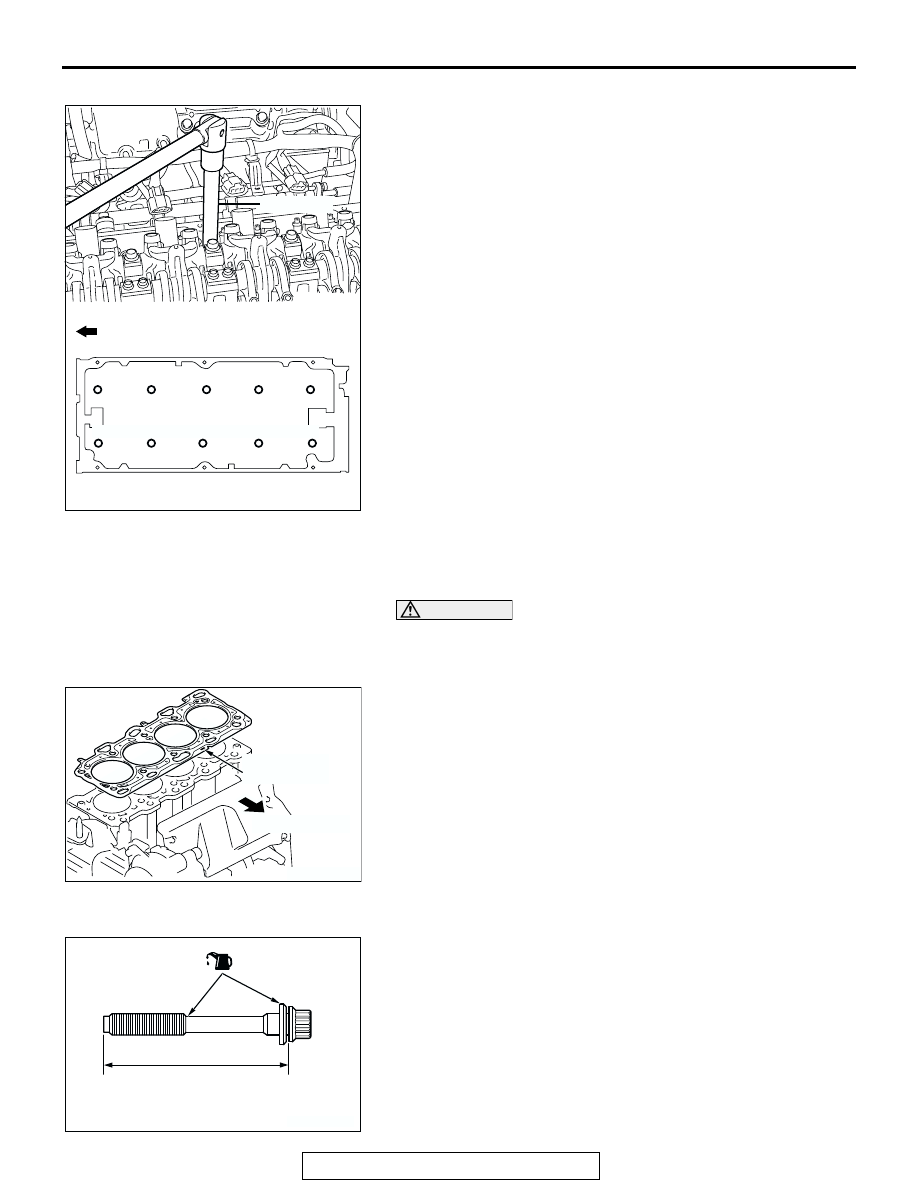

<<D>> CYLINDER HEAD BOLTS REMOVAL

Use special tool MB991654 to loosen the cylinder head bolts in

two or three steps in the order of the numbers shown in the

illustration. If the cylinder head bolts cannot be pulled out due

to the washer being trapped in the valve spring, raise the bolt

slightly, then remove it while holding it by using a magnet.

INSTALLATION SERVICE POINTS

.

>>A<< CYLINDER HEAD GASKET INSTALLATION

CAUTION

Do not allow any foreign materials get into the coolant pas-

sages, oil passages and cylinder.

1. Degrease the cylinder head gasket mounting surface.

2. Assemble to the cylinder block so the cylinder head gasket

identification mark of "381" is at the top surface and on the

exhaust side.

.

>>B<< CYLINDER HEAD BOLTS INSTALLATION

1. Check that the nominal length of each cylinder head bolt

meets the limit. If it exceeds the limit, replace the bolts with a

new one.

Limit (A): 99.4 mm (3.91 inches)

2. Apply a small amount of engine oil to the thread of the bolts

and to the washers.

AC301454AB

ENGINE FRONT

MB991654

10

5

2

8

3

9

7

4

6

1

AC302180AB

IDENTIFICATION

MARK "381"

EXHAUST SIDE

AC102537

A

AC

(ENGINE OIL)