Content .. 1402 1403 1404 1405 ..

Mitsubishi Galant (2004+). Manual - part 1404

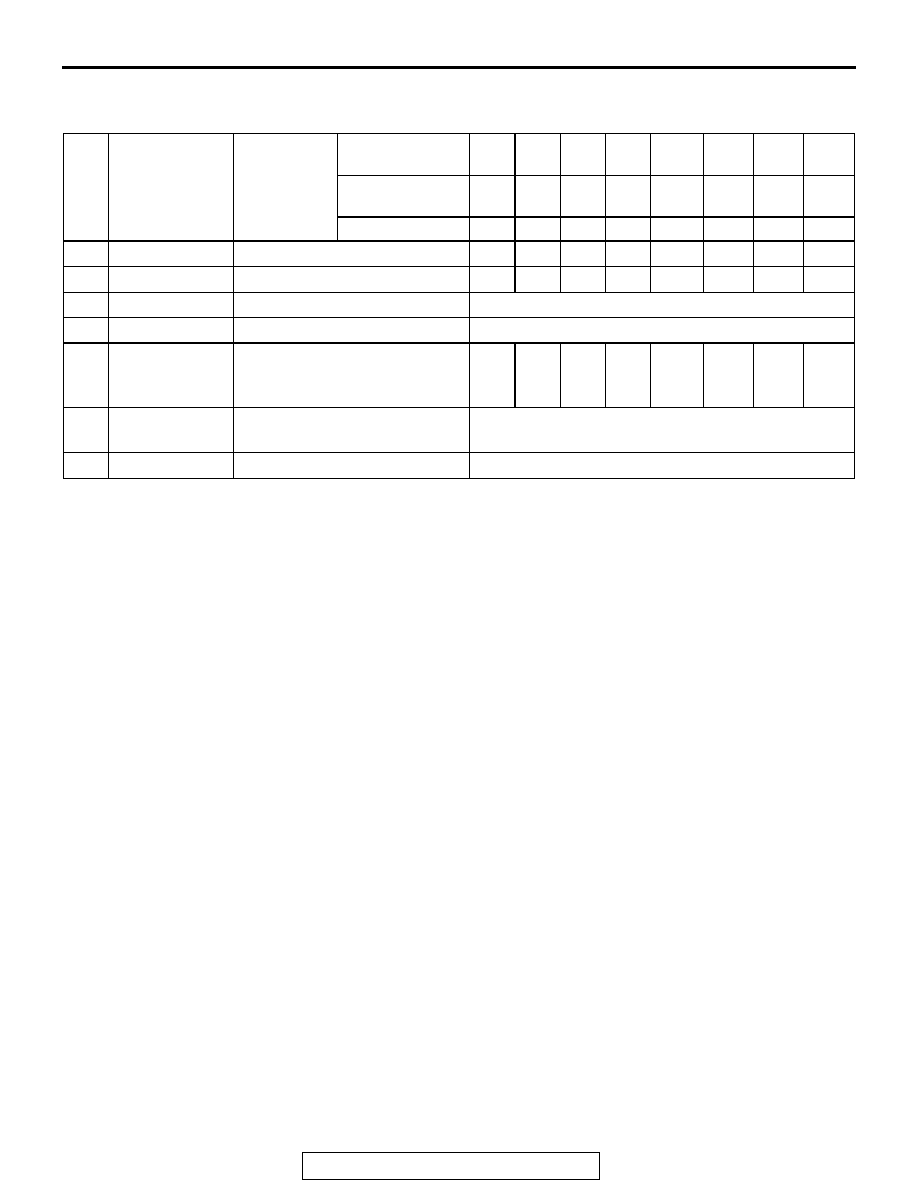

SCHEDULED MAINTENANCE TABLE

TSB Revision

GENERAL

00-39

SCHEDULED MAINTENANCE UNDER SEVERE USAGE CONDITIONS

Maintenance should be carried out according to the following table:

Severe usage conditions:

1. Driving on dusty, rough, muddy or salt-spread roads

2. Towing or police, taxi or commercial operation

3. Extensive idling and/or low speed operation

4. Repeated short-trip operation at freezing temperatures (engine not thoroughly warmed up)

5. Extended use of brakes while driving

6. Driving in sandy areas

7. More than 50% operation in heavy city traffic during hot weather above 90

°F (32°C)

NO.

MAINTENANCE

ITEM

SERVICE

INTERVALS

KILOMETERS IN

THOUSANDS

24

48

72

96

120

144

168

192

MILEAGE IN

THOUSANDS

15

30

45

60

75

90

105

120

MONTHS

12

24

36

48

60

72

84

96

3

Air cleaner filter Replace

X

X

X

X

X

X

X

X

5

Spark plugs

Replace

X

10

Engine oil

Change

Every 3 months or every 6,000 km (3,750 miles)

11

Engine oil filter Replace

Every 3 months or every 6,000 km (3,750 miles)

12

Transmission

fluid

Change fluid

X

chec

k

X

X

chec

k

X

X

check

X

X

chec

k

X

15

Disc brake

pads, rotors

Inspect for wear

Every 6 months or every 12,000 km (7,500 miles)

21

Tires

Rotate

Every 3 months or every 6,000 km (3,750 miles)