Content .. 1266 1267 1268 1269 ..

Mitsubishi Galant (2004+). Manual - part 1268

MULTIPORT FUEL INJECTION (MFI) DIAGNOSIS

TSB Revision

MULTIPORT FUEL INJECTION (MFI) <3.8L ENGINE>

13B-765

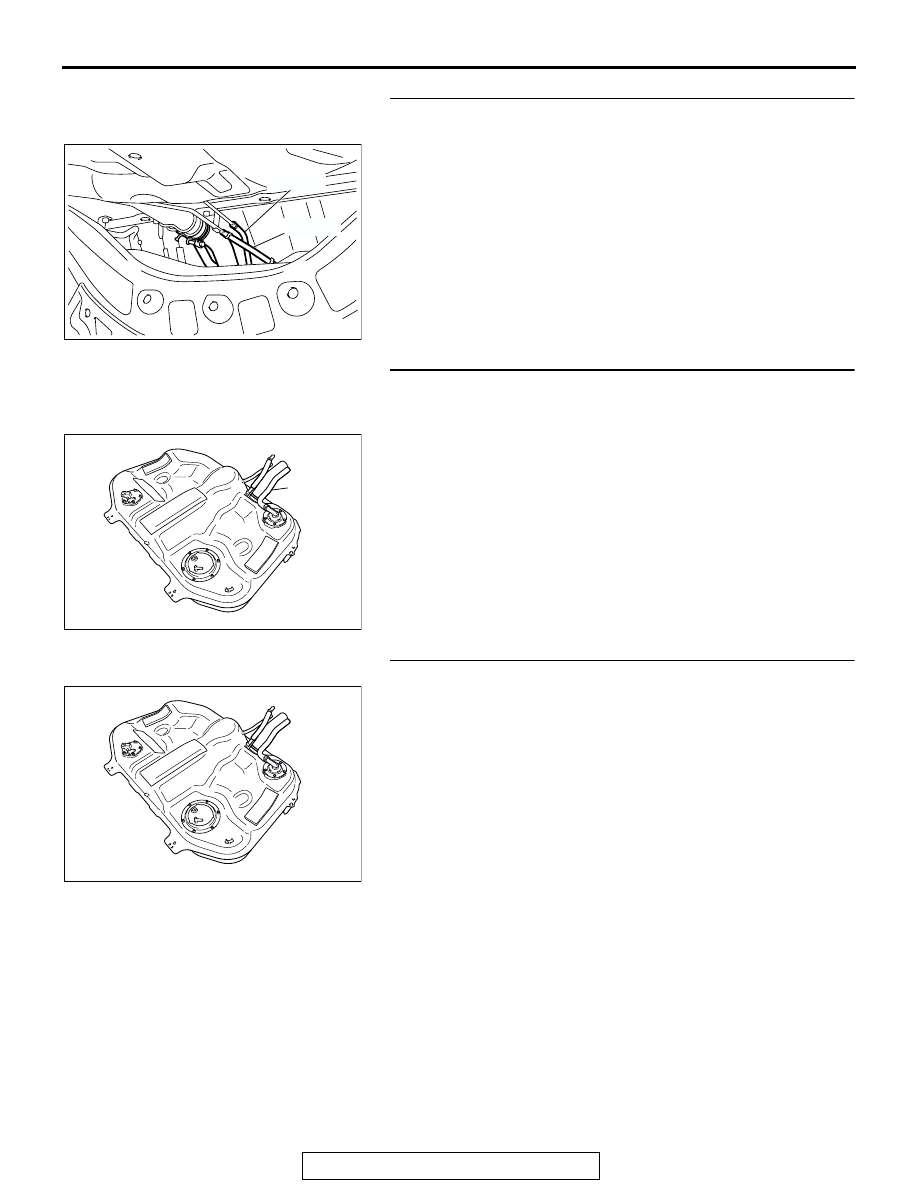

STEP 10. Check for leaks in evaporative emission hoses K

and L.

Use a hand vacuum pump to test each hose K and L.

Q: Do the hoses hold vacuum?

YES : Go to Step 11.

NO : Replace any damaged hose. Then go to Step 19.

STEP 11. Check for leaks in evaporative emission hose M.

(1) Remove the fuel tank assembly (Refer to GROUP 13C,

Fuel Tank

(2) Use the hand vacuum pump to check the hose M.

Q: Is the hose hold vacuum?

YES : Go to Step 12.

NO : Replace the hose and reinstall the fuel tank assembly

(Refer to GROUP 13C, Fuel Tank

). Then go

to Step 19.

STEP 12. Check for leaks in the fuel tank.

(1) Visually check for cracks or other leaks in the fuel tank.

NOTE: Carefully check the fuel pump module and the fuel

tank differential pressure sensor installation in the fuel tank.

AC306776

AC

HOSE L

HOSE K

AC305683AC

HOSE M

AC305683