Content .. 1180 1181 1182 1183 ..

Mitsubishi Galant (2004+). Manual - part 1182

MULTIPORT FUEL INJECTION (MFI) DIAGNOSIS

TSB Revision

MULTIPORT FUEL INJECTION (MFI) <3.8L ENGINE>

13B-421

Check Conditions

• Engine coolant temperature is higher than 76°C

(169

°F).

• Under the closed loop air/fuel ratio control.

Judgment Criteria

• Long-term fuel trim has continued to be −12.5

percent for 5 seconds.

or

• Short-term fuel trim has continued to be −30.0

percent for 5 seconds.

.

OBD-II DRIVE CYCLE PATTERN

Refer to Diagnostic Function

− OBD-II Drive Cycle −

Procedure 2

− Fuel Trim Monitor

.

TROUBLESHOOTING HINTS (The most likely

causes for this code to be set are:)

• Mass airflow sensor failed.

• Injector (Number 1, 3, 5) failed.

• Incorrect fuel pressure.

• Engine coolant temperature sensor failed.

• Intake air temperature sensor failed.

• Barometric pressure sensor failed.

• Manifold absolute pressure sensor failed.

• Harness damage in right bank injector circuit, or

connector damage.

• PCM failed.

DIAGNOSIS

Required Special Tools:

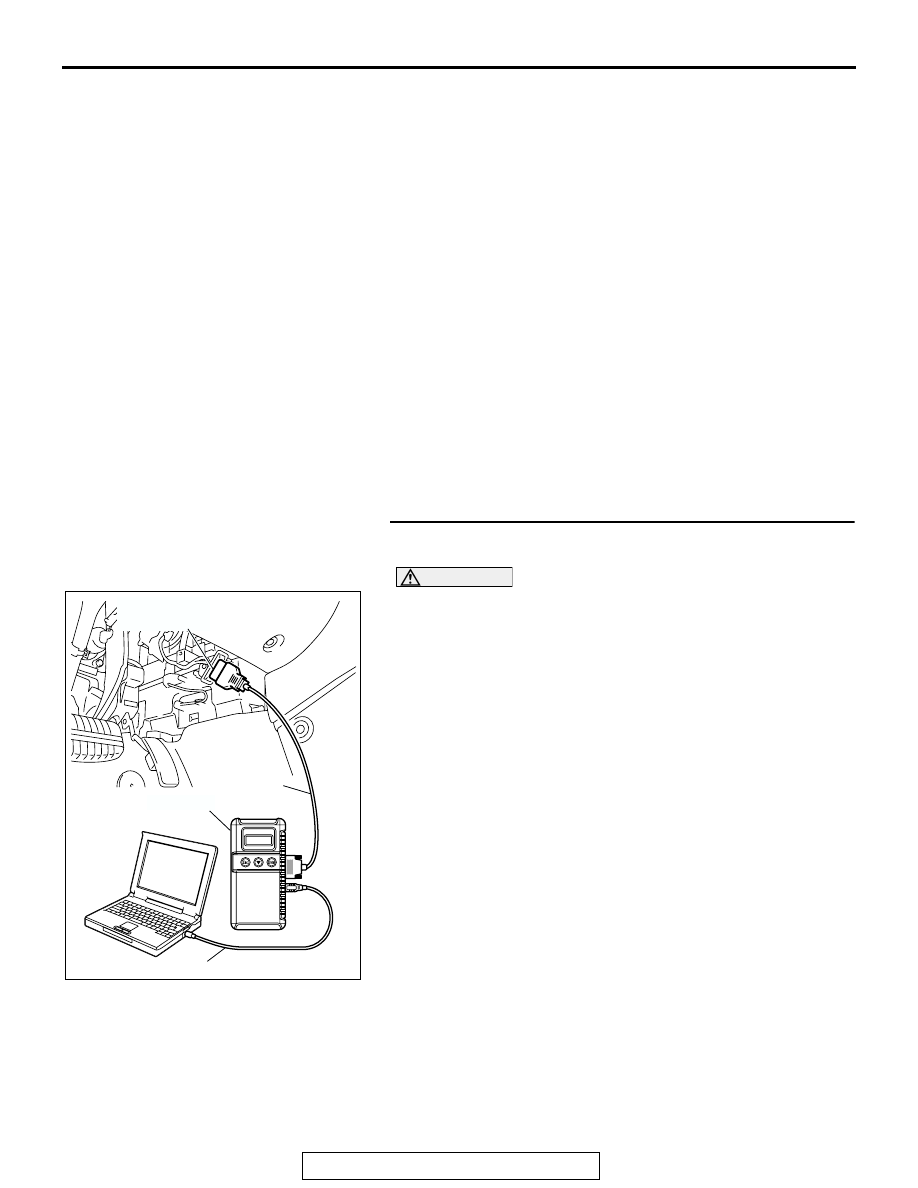

• MB991958: Scan Tool (MUT-III Sub Assembly)

• MB991824: V.C.I.

• MB991827: USB Cable

• MB991910: Main Harness A

STEP 1. Using scan tool MB991958, check data list item 12:

Mass Airflow Sensor.

CAUTION

To prevent damage to scan tool MB991958, always turn the

ignition switch to the "LOCK" (OFF) position before con-

necting or disconnecting scan tool MB991958.

(1) Connect scan tool MB991958 to the data link connector.

(2) Start the engine and run at idle.

(3) Set scan tool MB991958 to the data reading mode for item

12, Mass Airflow Sensor.

(4) Warm up the engine to normal operating temperature: 80

°C

to 95

°C (176°F to 203°F).

• When idling, between 2.0 and 6.0 g/sec.

• When 2,500 r/min, between 8.0 and 16.0 g/sec.

(5) Turn the ignition switch to the "LOCK" (OFF) position.

Q: Is the sensor operating properly?

YES : YES: Go to Step 2.

NO : Refer to DTC P0101

− Mass Airflow Circuit

, DTC P0102

− Mass Airflow Circuit Low Input

, DTC

P0103

− Mass Airflow Circuit High Input

.

AC305412

AB

MB991910

DATA LINK

CONNECTOR

MB991824

MB991827