Mitsubishi Galant. Manual - part 386

GENERAL DESCRIPTION

TSB Revision

AUTOMATIC TRANSAXLE

23A-11

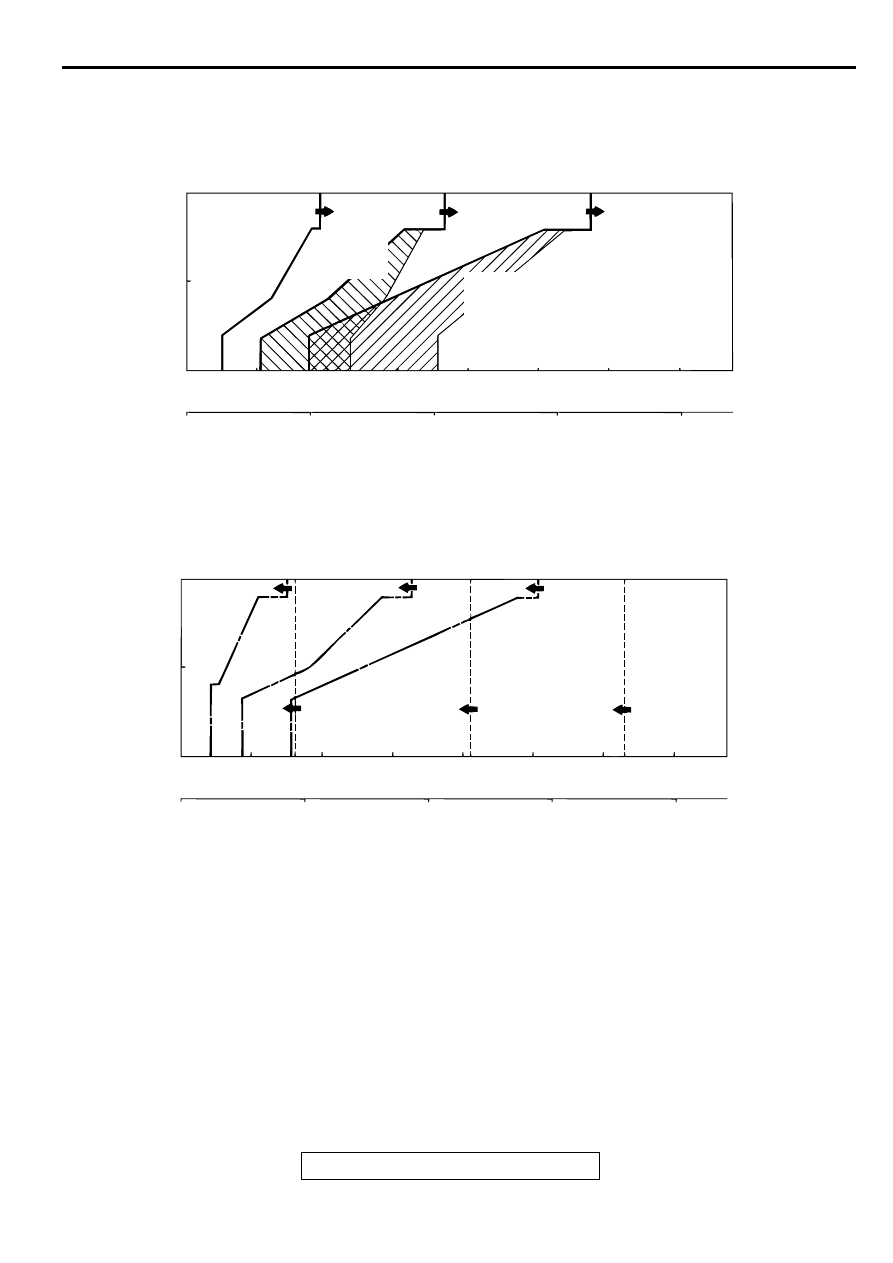

SHIFT PATTERN CONTROL

<2.4L ENGINE> UPSHIFT PATTERN

<2.4L ENGINE> DOWNSHIFT PATTERN

AC001949AC

100

50

0

1,000

2,000

3,000

4,000

5,000

6,000

7,000

1

2

2

3

3

4

THROTTLE

OPENING (%)

2

→

3

MOVEMENT

RANGE

3

→

4

MOVEMENT

RANGE

0 (0)

50 (31)

100 (62)

150 (93)

200 (124)

OUTPUT SHAFT SPEED (r/min)

VEHICLE SPEED [km/h (mph)]

THICK LINE: STANDARD SHIFT PATTERN

AC001950

100

50

0

0(0)

1,000

2,000

3,000

4,000

5,000

6,000

7,000

50 (31)

100 (62)

150 (93)

200 (124)

1

2

2

3

3

4

1

2 (L)

2

3 (2,L)

3

4 (3,2,L)

THROTTLE

OPENING (%)

OUTPUT SHAFT SPEED (r/min)

VEHICLE SPEED [km/h (mph)]

AC