Mitsubishi Galant 9G. Manual - part 822

MULTIPORT FUEL INJECTION (MFI) DIAGNOSIS

TSB Revision

MULTIPORT FUEL INJECTION (MFI) <2.4L ENGINE>

13A-730

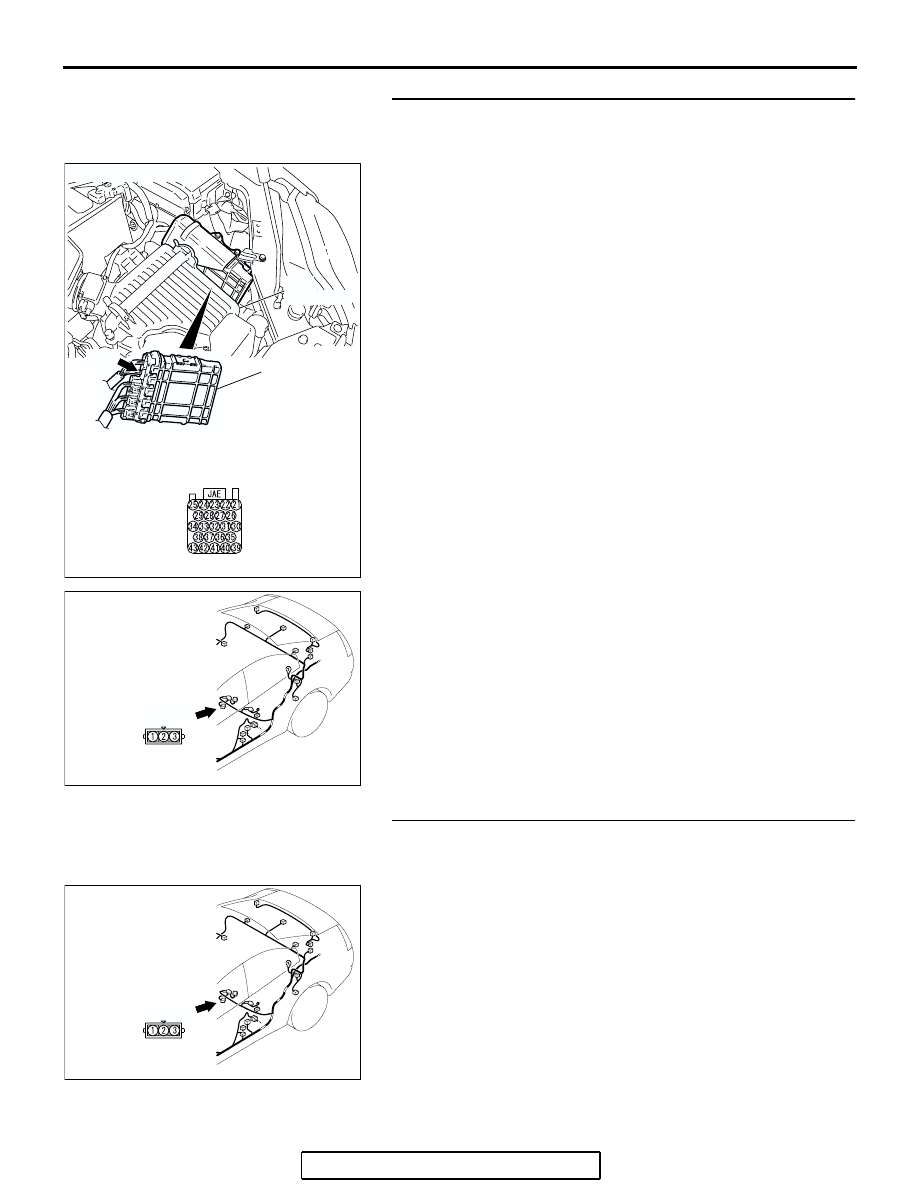

STEP 14. Check the harness wires between PCM

connector B-20 terminal 22 and fuel tank differential

pressure sensor connector D-23 terminal 2 for damage.

Q: Are the harness wires in good condition?

YES : Go to Step 17.

NO : Repair the damaged harness wires. Then go to Step

STEP 15. Check fuel tank differential pressure sensor

connector D-23 for loose, corroded or damaged terminals,

or terminals pushed back in the connector.

Q: Is the connectors and terminals in good condition?

YES : Replace the fuel tank differential pressure sensor.

Then go to Step 17.

NO : Repair or replace the faulty components (Refer to

GROUP 00E, Harness Connector Inspection

AC306248

B-20 HARNESS

CONNECTOR:

COMPONENT SIDE

AB

B-20

CONNECTOR: B-20

PCM

AIR

CLEANER

AC305266

CONNECTOR: D-23

AB

D-23 (B)

AC305266

CONNECTOR: D-23

AB

D-23 (B)