Mitsubishi Galant 9G. Manual - part 475

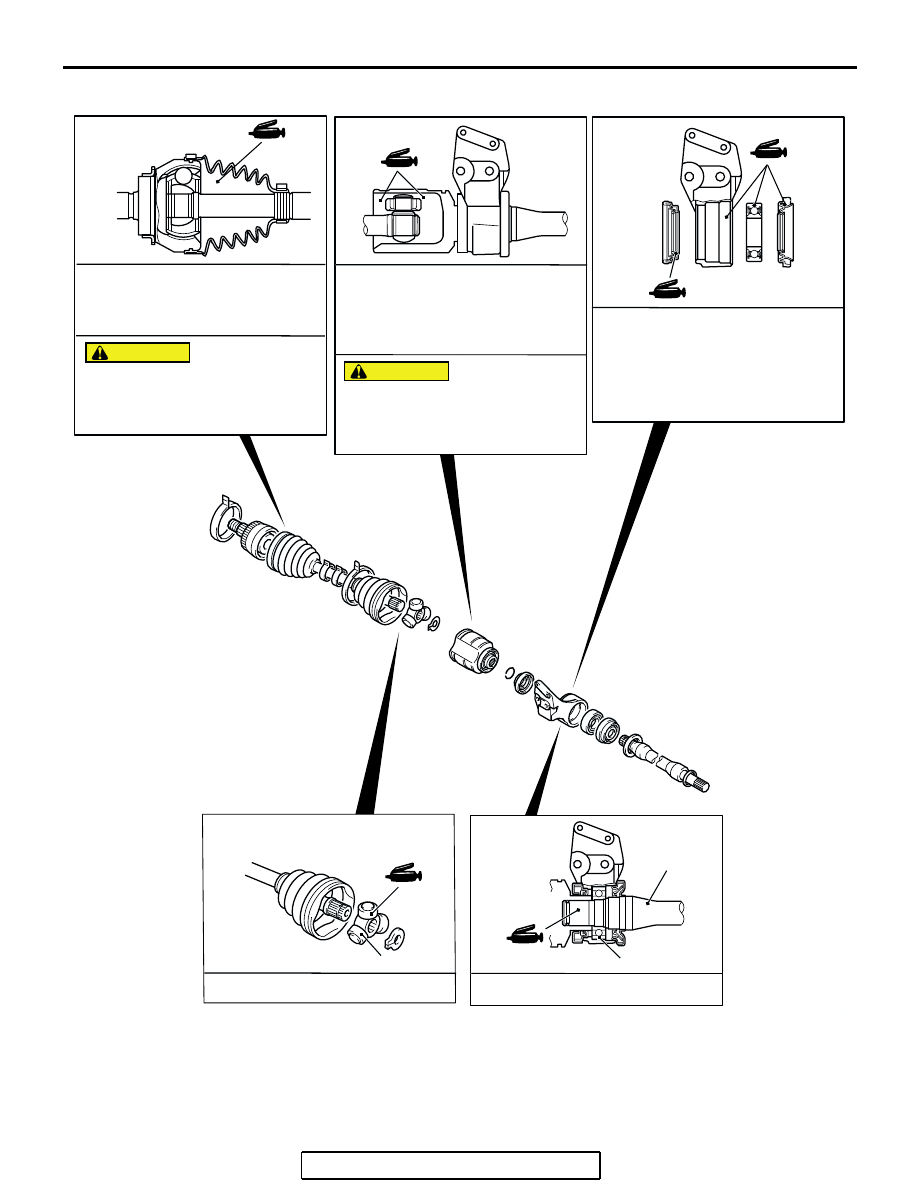

DRIVE SHAFT ASSEMBLY

TSB Revision

FRONT AXLE

26-20

LUBRICATION POINTS

AC305985

GREASE: REPAIR KIT GREASE

AMOUNT USED: 120 ± 10 g

(4.2 ± 0.3 oz)<2.4L>, 165 ± 10 g

(5.8 ± 0.3 oz)<3.8L>

CAUTION

THE DRIVE SHAFT JOINT USES

SPECIAL GREASE. DO NOT MIX OLD

AND NEW OR DIFFERENT TYPES OF

GREASE.

GREASE: REPAIR KIT GREASE

AMOUNT USED: 140 ± 10 g

(4.9 ± 0.3 oz)<2.4L-LH>, 130 ± 10 g

(4.6 ± 0.3 oz)<2.4L-RH>, 220 ± 10 g

(7.8 ± 0.3 oz)<3.8L>

GREASE: REPAIR KIT GREASE

AMOUNT USED:

DUST SEAL INNER: 14 - 20 g

(0.5 - 0.7 oz)

DUST SEAL OUTER: 8 - 12 g

(0.3 - 0.4 oz)

THE DRIVE SHAFT JOINT USES

SPECIAL GREASE. DO NOT MIX OLD

AND NEW OR DIFFERENT TYPES OF

GREASE.

CAUTION

GREASE: REPAIR KIT GREASE

AB

14

GREASE: REPAIR KIT GREASE

10

5