Mitsubishi Galant 9G. Manual - part 469

EMISSION CONTROL

TSB Revision

ENGINE AND EMISSION CONTROL

17-94

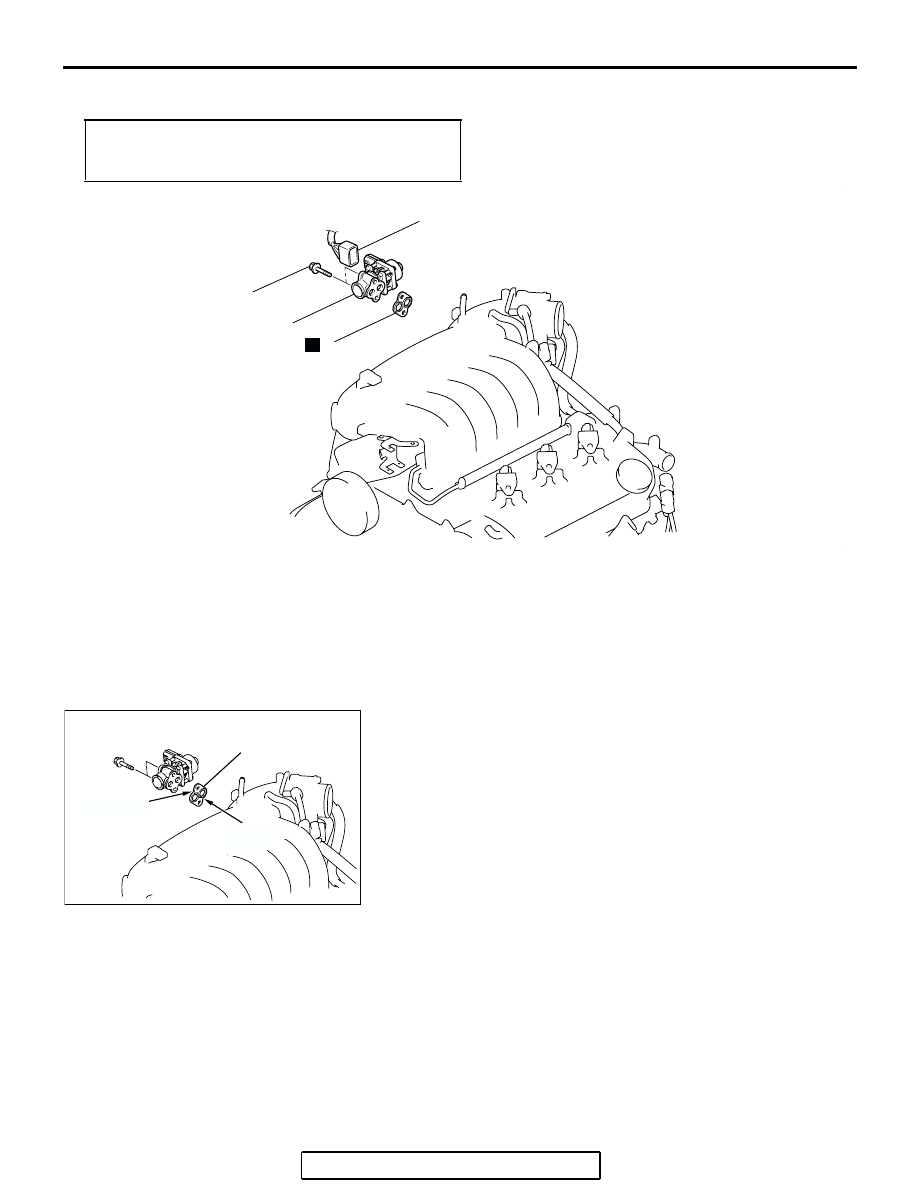

REMOVAL AND INSTALLATION <3.8L ENGINE>

M1173010500205

INSTAIIATION SERVICE POINT

.

>>A<< EGR VALVE GASKET INSTALLATION

Install the EGR valve gasket as shown in the illustration.

Pre-removal and Post-installation Operation

Strut Tower Bar Removal and Installation (Refer to GROUP

42, Strut Tower Bar

AC307978AB

24 ± 3 N·m

18 ± 2 ft-lb

N

1

2

3

REMOVAL STEPS

1. EGR VALVE CONNECTOR

2. EGR VALVE

>>A<<

3. EGR VALVE GASKET

REMOVAL STEPS (Continued)

AC307979AB

GASKET

NOTCHED

PART

NOTCHED

PART