Mitsubishi Galant 9G. Manual - part 428

MAINTENANCE SERVICE

TSB Revision

GENERAL

00-50

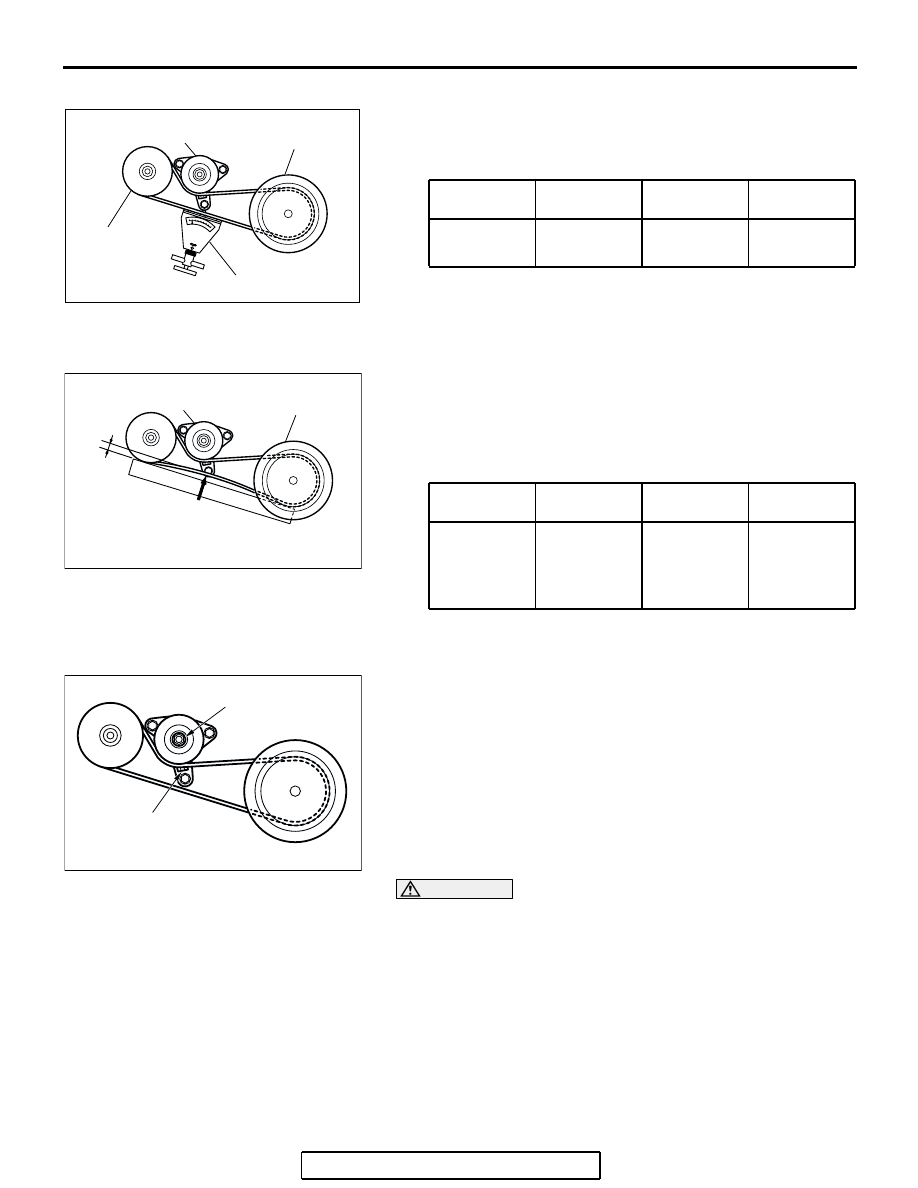

WHEN USING A TENSION GAUGE

Use a belt tension gauge to check that the belt tension is within

the standard value.

Standard value:

.

BELT DEFLECTION CHECK

Apply approximately 98 N (22 lb) of force to the middle of the

drive belt between the pulleys (at the place indicated by the

arrow) and check that the amount of deflection is within the

standard value.

Standard value:

.

if the tension or deflection is outside the standard value, adjust

by the following procedure.

1. Loosen the tensioner pulley lock nut.

2. Adjust the belt tension to the standard value by turning the

adjusting bolt. The tension will increase when turning the

adjusting bolt clockwise, and decrease when turning

counterclockwise.

3. Tighten the lock nut to the specified torque.

Tightening torque: 49

± 9 N⋅m (36 ± 7 ft-lb)

4. Tighten the adjusting bolt.

Tightening torque: 5.0

± 1.0 N⋅m (44 ± 9 in-lb)

CAUTION

Check after turning the crankshaft one or more rotations

clockwise.

5. Check the belt deflection amount and tension, and readjust

if necessary.

ITEM

WHEN

CHECKED

DURING

ADJUSTMENT

DURING

REPLACEMENT

Tension N

(lb)

294

− 490

(66

− 110)

343

− 441

(77

− 99)

490

− 686

(110

− 154)

AC210249AB

TENSION

GAUGE

POWER

STEERING

OIL PUMP

PULLEY

CRANKSHAFT

PULLEY

TENSION

PULLEY

ITEM

WHEN

CHECKED

DURING

ADJUSTMENT

DURING

REPLACEMENT

Deflection

(Reference

value) mm

(in)

12.3

− 16.2

(0.48

− 0.64)

13.2

− 15.1

(0.52

− 0.59)

9.6

− 12.3

(0.38

− 0.48)

AC210250AB

APPROXIMATELY

98 N (22 lb)

CRANKSHAFT

PULLEY

TENSION

PULLEY

AC210301

ADJUSTING

BOLT

LOCK NUT

AB