Content .. 1384 1385 1386 1387 ..

Mitsubishi Galant 9G. Manual - part 1386

OIL PAN AND OIL SCREEN

TSB Revision

ENGINE MECHANICAL <3.8L ENGINE>

11C-38

INSTALLATION SERVICE POINTS

.

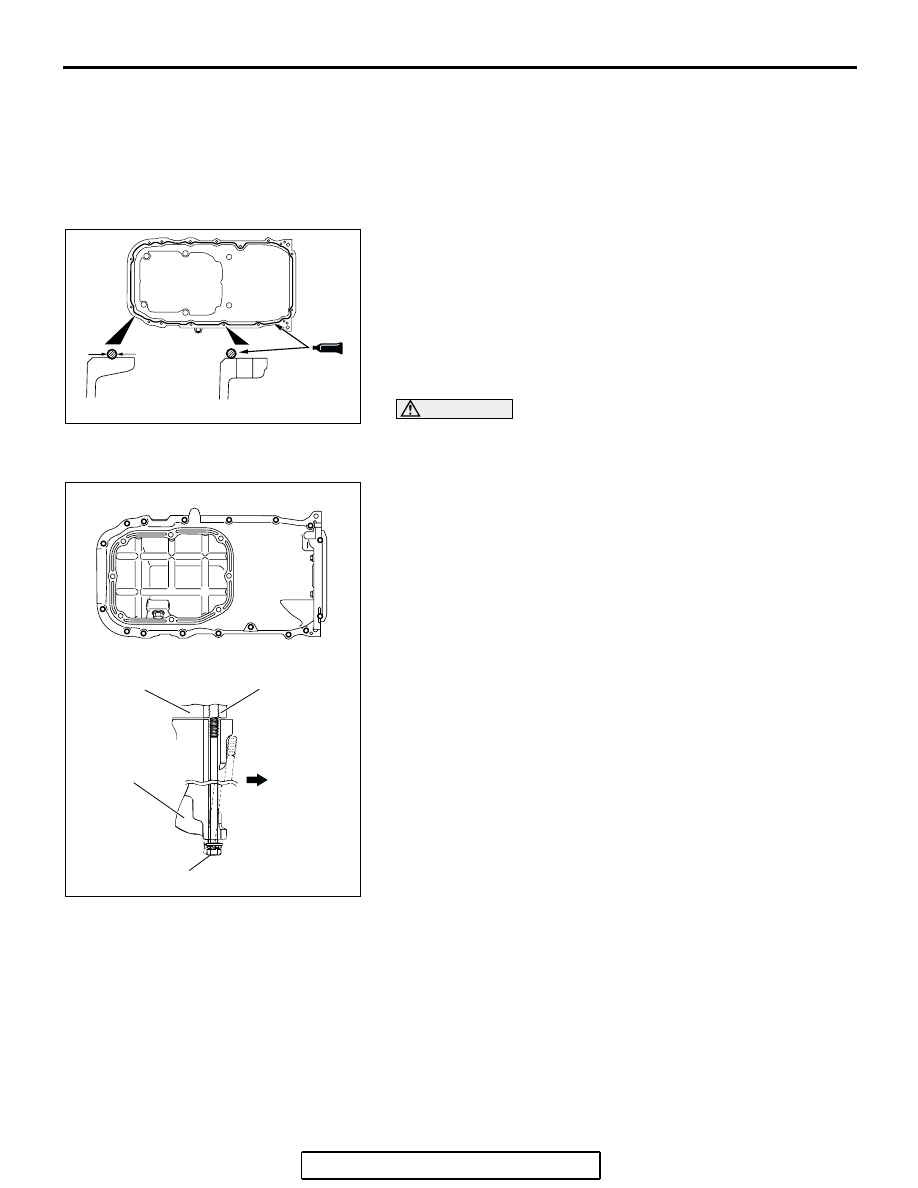

>>A<< ENGINE UPPER OIL PAN INSTALLATION

1. Remove sealant from the oil pan and cylinder block mating

surfaces.

2. Degrease the sealant-coated surface and the engine mating

surface.

3. Apply a bead of the sealant to the cylinder block mating

surface of the engine oil pan as shown.

Specified sealant: 3M

AAD Part No.8672, 8704, 3M

AAD Part No.8679/8678 or equivalent

NOTE: The sealant should be applied in a continuous bead

approximately 4.0 mm (0.16 inch) in diameter.

4. Assemble the oil pan to the cylinder block within 15 minutes

after applying the sealant.

CAUTION

The bolt holes for bolts 13 and 14 in the illustration are cut

away on the transaxle side. Be careful not to insert these

bolts at an angle.

5. Tighten the bolts in order of the numbers shown in the

illustration.

.

AC308675

Ø 4.0 mm

(0.16 in)

GROOVE

PORTION

BOLT HOLE

PORTION

AB

AC206507

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

AB

CYLINDER BLOCK

REAR OIL SEAL CASE

OIL PAN

TRANSAXLE

SIDE

13, 14