Content .. 1378 1379 1380 1381 ..

Mitsubishi Galant 9G. Manual - part 1380

ON-VEHICLE SERVICE

TSB Revision

ENGINE MECHANICAL <3.8L ENGINE>

11C-14

1. Check engine oil and add or change oil if required.

NOTE: If the engine oil level is low, air is sucked from the oil

screen, causing air to enter the oil passage.

NOTE: If the engine oil level is higher than specification, oil

may be stirred by the crankshaft, causing oil to be mixed

with a large quantity of air.

NOTE: If oil is deteriorated, air is not easily separated from

oil, increasing the quantity of air contained in oil.

NOTE: If air mixed with oil enters the high pressure chamber

inside the lash adjuster from the above causes, air in the

high pressure chamber is compressed excessively while the

valve is opened, resulting in an abnormal noise when the

valve closes. This is the same phenomenon as that

observed when the valve clearance has become excessive.

The lash adjuster can resume normal function when air

entered the lash adjuster is removed.

2. Idle the engine for one to three minutes to warm it up.

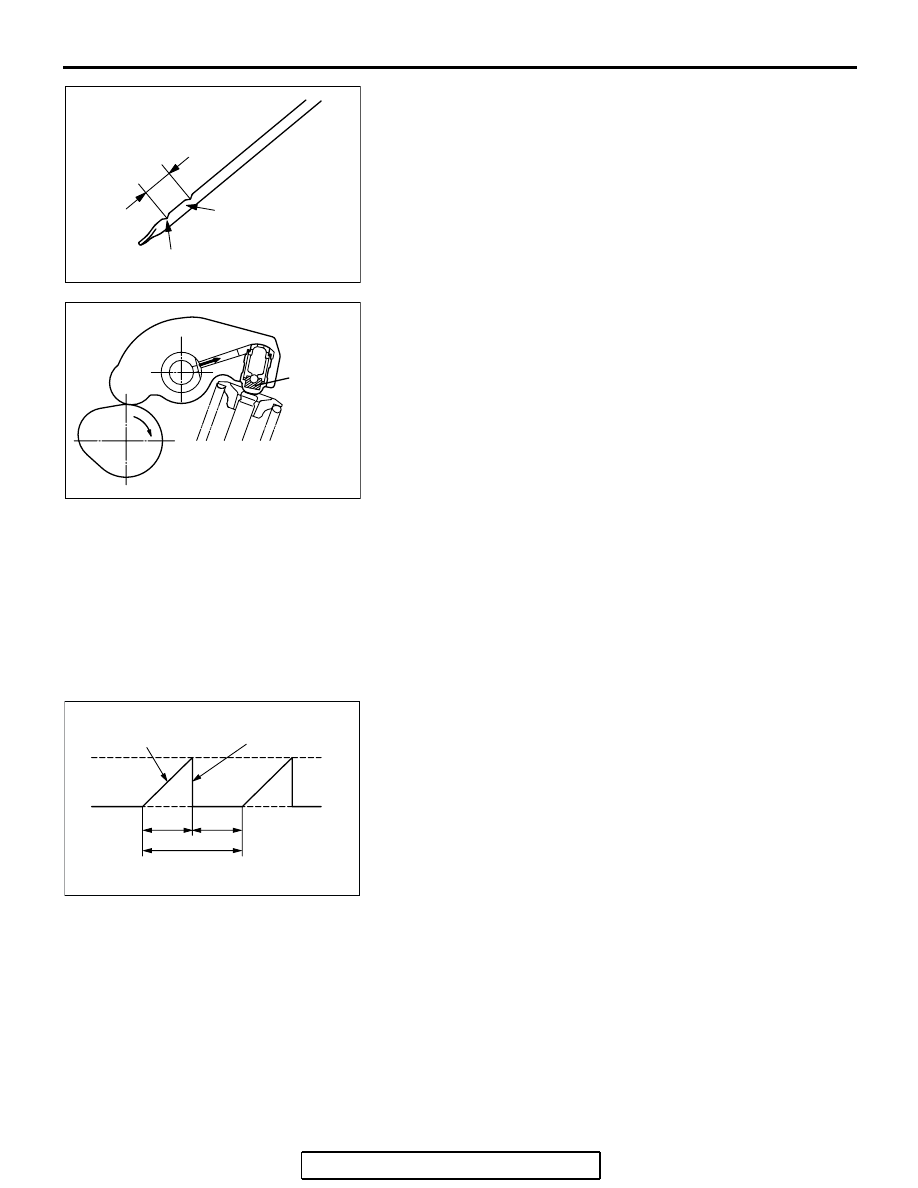

3. Repeat the operation pattern, shown in left figure, at no load

to check for abnormal noise. (Usually the abnormal noise is

eliminated after repetition of the operation 10 to 30 times. If,

however, no change is observed in the level of abnormal

noise after repeating the operation more than 30 times,

suspect that the abnormal noise is due to some other

factors.)

4. After elimination of abnormal noise, repeat the operation

shown in left figure five more times.

5. Run the engine at idle for one to three minutes to make sure

that the abnormal noise has been eliminated.

AKX00328

GOOD

MINIMUM

MAXIMUM

AB

AKX00329

HIGH-

PRESSURE

CHAMBER

AB

AKX00330

OPEN THROTTLE

VALVE GRADUALLY

CLOSE

THROTTLE VALVE

APPROXI-

MATELY

3,000 r/min

IDLING

OPERATION

ONCE

15 s

15 s

AIR BLEEDING OPERATION PATTERN

AB