Content .. 1371 1372 1373 1374 ..

Mitsubishi Galant 9G. Manual - part 1373

DIAGNOSIS

TSB Revision

CONTROLLER AREA NETWORK (CAN)

54C-596

TROUBLE JUDGMENT

If the MUT-III cannot received signals from the

SRS-ECU, CAN bus line connector(s) are broken or

an open circuit has occurred.

.

COMMENTS ON TROUBLE SYMPTOM

The wiring harness wire or connectors may have

loose, corroded, or damage terminals, or terminals

pushed back in the connector, or the SRS-ECU may

be defective.

.

TROUBLESHOOTING HINTS

• The wiring harness or connectors may have

loose, corroded, or damage terminals, or termi-

nals pushed back in the connector

• The SRS-ECU may be defective

DIAGNOSIS

Required Special Tool:

• MB991223: Harness Set

STEP 1. Check intermediate connector C-22 and SRS-ECU

connector C-121 for loose, corroded or damaged

terminals, or terminals pushed back in the connector.

CAUTION

The strand end of the twisted wire should be within 10 cm

(4 inches) from the connector. For details refer to

Q: Are intermediate connector C-22 and SRS-ECU

connector C-121 in good condition?

YES : Go to Step 2.

NO : Repair the damaged parts. Replace the joint

connector as necessary.

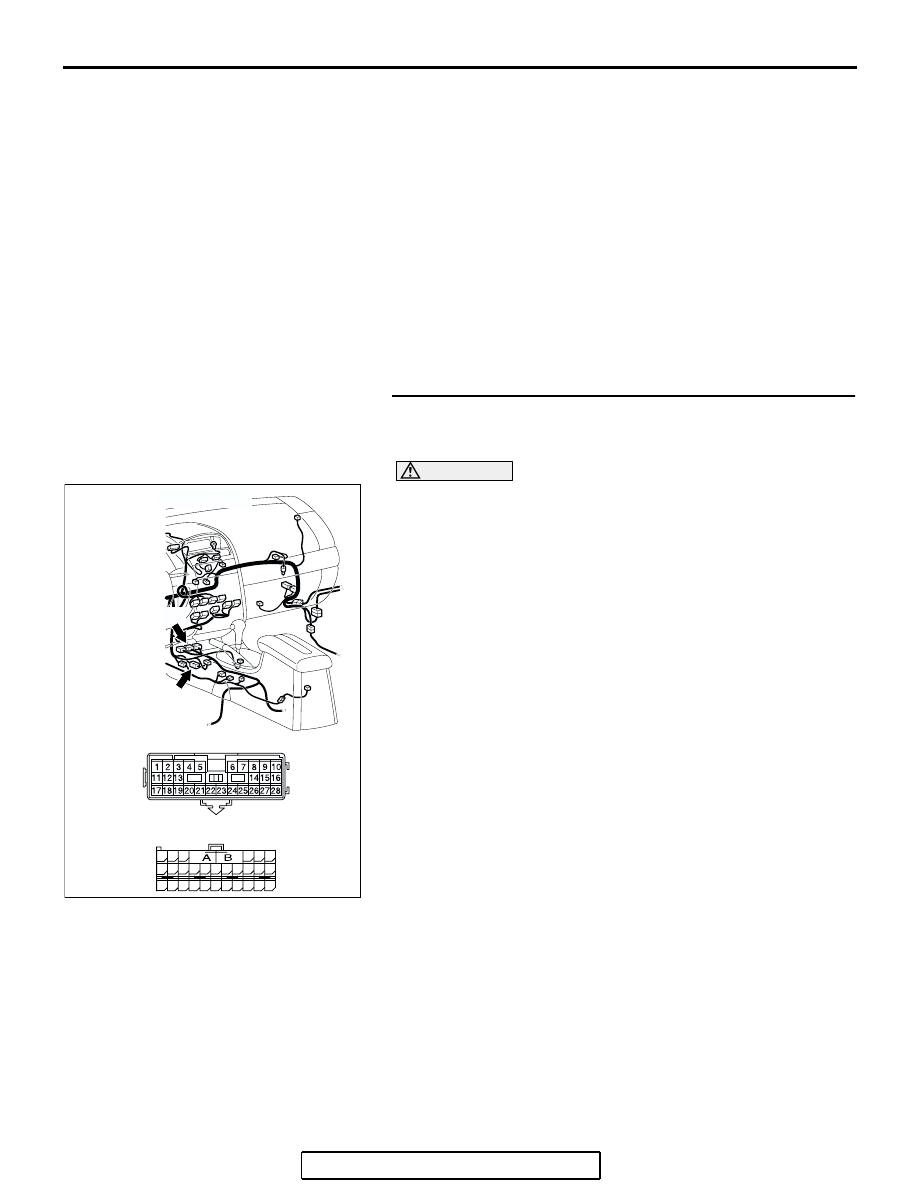

AC305234AC

CONNECTORS: C-22, C-121

C-121 HARNESS SIDE

C-121 (Y)

C-22 (Y)

C-22

48

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47