Content .. 1122 1123 1124 1125 ..

Mitsubishi Galant 9G. Manual - part 1124

MULTIPORT FUEL INJECTION (MFI) DIAGNOSIS

TSB Revision

MULTIPORT FUEL INJECTION (MFI) <3.8L ENGINE>

13B-796

Q: Is the fuel tank pressure between

−1.5 and 1.5 kPa

(

−0.443 and 0.443 inHg)?

YES : It can be assumed that this malfunction is intermittent

(Refer to GROUP 00, How to Use

Troubleshooting/Inspection Service Points

− How to

Cope with Intermittent Malfunctions

). Go to

Step 17.

NO : Replace the PCM (Refer to

). Then go to

Step 17 .

STEP 17. Perform the OBD-II drive cycle.

(1) Carry out a test drive with the drive cycle pattern (Refer to

Diagnostic Function

− OBD-ll Drive Cycle − Procedure 1 −

Evaporative Emission System Leak Monitor

(2) Read the diagnostic trouble code (DTC).

Q: Is DTC P0453 set?

YES : Repeat the troubleshooting from Step 2.

NO : The procedure is complete.

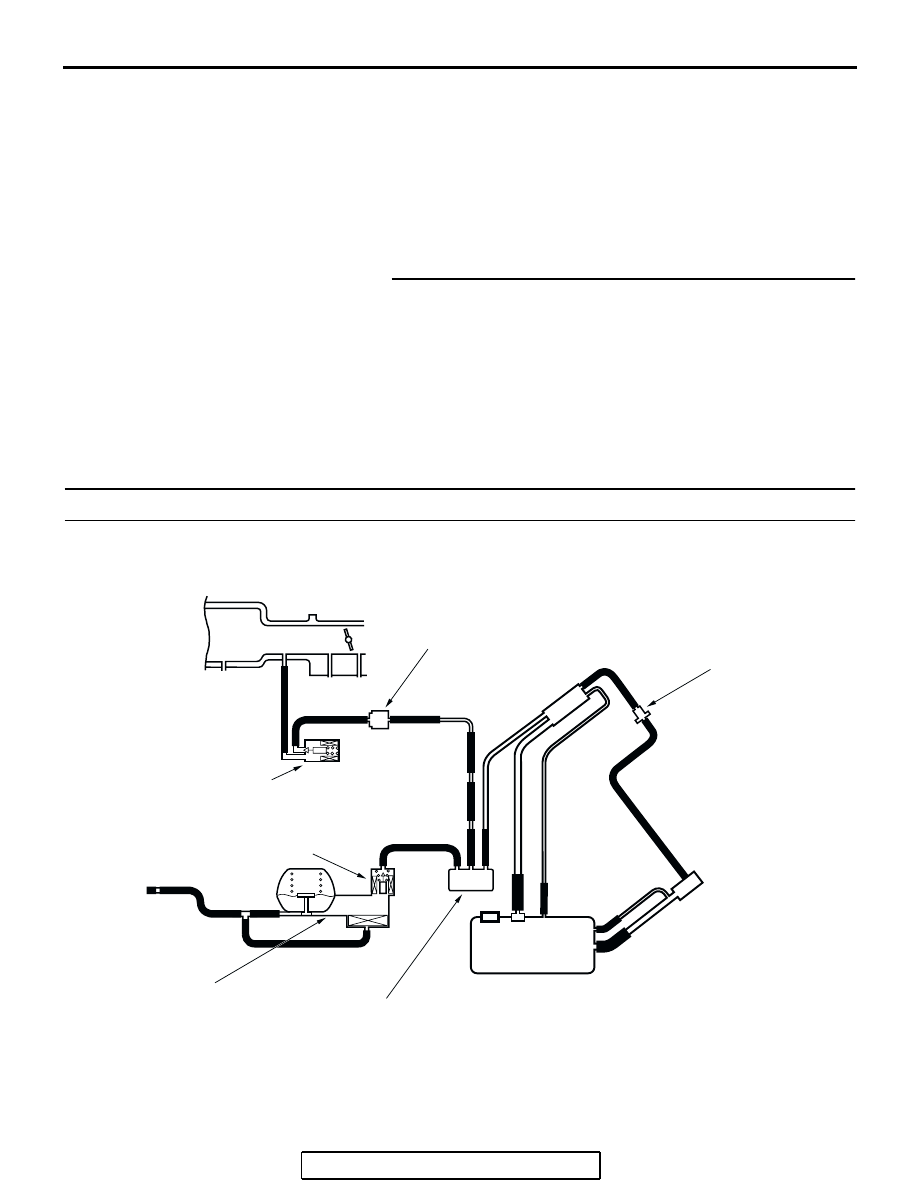

DTC P0455: Evaporative Emission System Leak Detected (Gross Leak)

AC306278

A

B

C

D

E

F

G

O

P

Q

N

M

L

H

I

J

K

AB

INTAKE MANIFOLD PLENUM

FUEL TANK

EVAPORATIVE EMISSION

VENTILATION SOLENOID

CHECK VALVE

EVAPORATIVE EMISSION

PURGE SOLENOID

EVAPORATIVE

EMISSION CANISTER

ONBOARD REFUELING

VAPOR RECOVERY(ORVR)

VENT VALVE MODULE

SYSTEM DIAGRAM

CHAMBER