Mitsubishi Pajero Pinin. Manual - part 311

SRS –

SRS Maintenance

52B-23

SRS MAINTENANCE

The SRS must be inspected by an authorized dealer 10 years

after the date of vehicle registration.

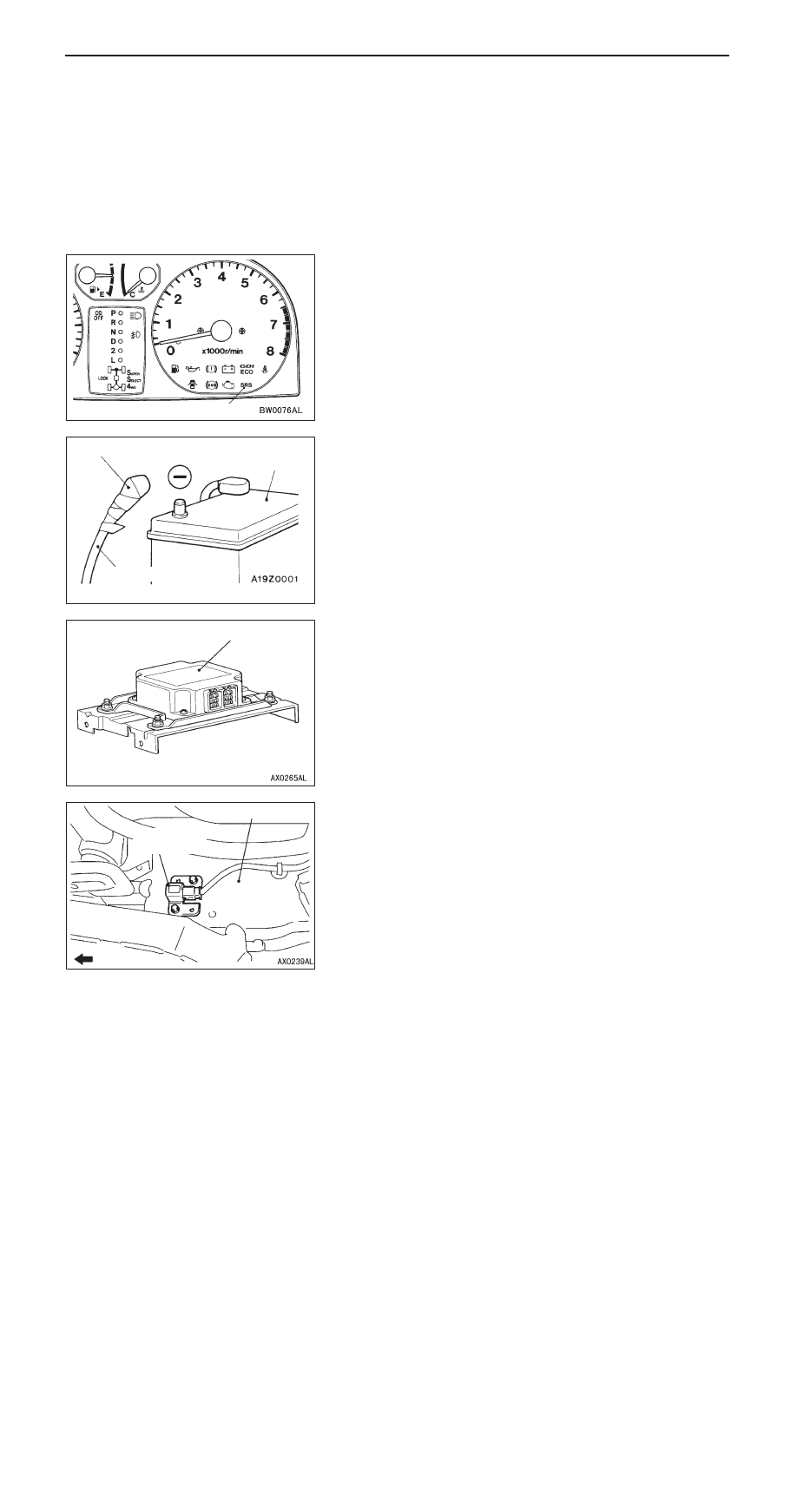

SRS WARNING LAMP CHECK

Turn the ignition switch to the “ON” position. Does the SRS

warning lamp illuminate for about 7 seconds, turn off and

then remain extinguished for at least 5 seconds? If yes, SRS

system is functioning properly. If no, consult page 52B-8.

SRS COMPONENT VISUAL CHECK

Turn the ignition key to LOCK (OFF) position, disconnect the

negative battery cable and tape the terminal.

Caution

Wait at least 60 seconds after disconnecting the battery

cable before doing any further work. (Refer to P.52B-4.)

SRS CONTROL UNIT (SRS-ECU)

1.

Check SRS-ECU case and brackets for dents, cracks,

deformation or rust.

Caution

The SRS may not activate if the SRS-ECU is not

installed properly, which could result in serious injury

or death to the vehicle’s driver or front passenger.

2.

Check connector for damage, and terminals for

deformation or rust.

Replace SRS-ECU if it fails visual check.

(Refer to P.52B-34.)

FRONT IMPACT SENSORS

1.

Check the front side member for deformation or rest.

2.

Check the front impact sensor for dents, cracks,

deformation or rust.

3.

Check the sensor harnesses for binding, the connectors

for damage, and the terminals for deformation.

SRS warning lamp

Battery (–) cable

Insulating tape

Battery

SRS-ECU

Front side member

Front impact

sensor

Forward