Mitsubishi Pajero Pinin. Manual - part 219

REAR AXLE –

Differential Carrier

27-26

2.

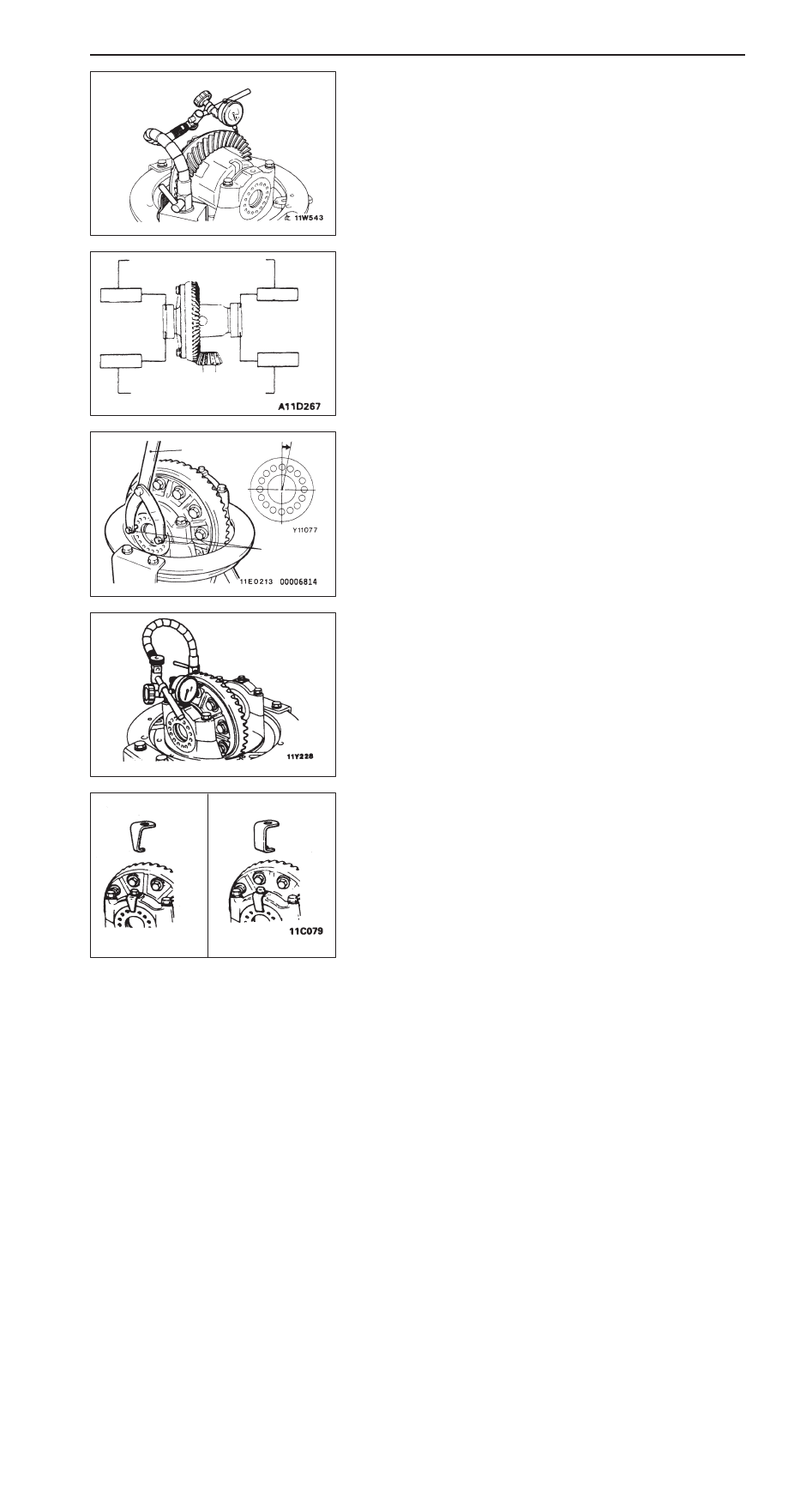

With the drive pinion locked in place, measure the drive

gear backlash with a dial indicator on the drive gear.

NOTE

Measure at four points or more on the circumference of

the drive gear.

Standard value: 0.08 – 0.13 mm

3.

If the drive gear backlash is not within the standard value,

use the special tools (MB991367 and MB991385) to tighten

or loosen the side bearing nuts as shown in the illustration,

in order to adjust the backlash.

NOTE

First loosen the side bearing nut, then tighten the side

bearing nut the same amount as when it was loosened.

4.

Use the special tools to turn down both right and left side

bearing nuts on half the distance between centres of two

neighboring holes, in order to apply the preload to the

side bearing.

5.

Measure the drive gear runout at the shoulder on the

reverse side of the drive gear.

Limit: 0.05 mm

6.

If the drive gear runout exceeds the limit, reinstall by

changing the phase of the drive gear and differential case,

and remeasure.

7.

If adjustment is not possible, replace the differential case

or limited slip differential case, or replace the drive gear

and drive pinion as a set.

8.

Select either of the lock plates, and then install it.

9.

Check the drive gear tooth contact. If poor contact is

evident, adjust the drive gear tooth contact. (Refer to

GROUP 26 – Differential carrier.)

Loosen

If backlash is too small

Tighten

If backlash is too large

Tighten

Loosen

MB991367

MB991385

MB092153

MB092154