Mitsubishi Pajero Pinin. Manual - part 205

FRONT AXLE –

Differential Carrier

26-39

"

E

A

DRIVE PINION ROTATION TORQUE

ADJUSTMENT

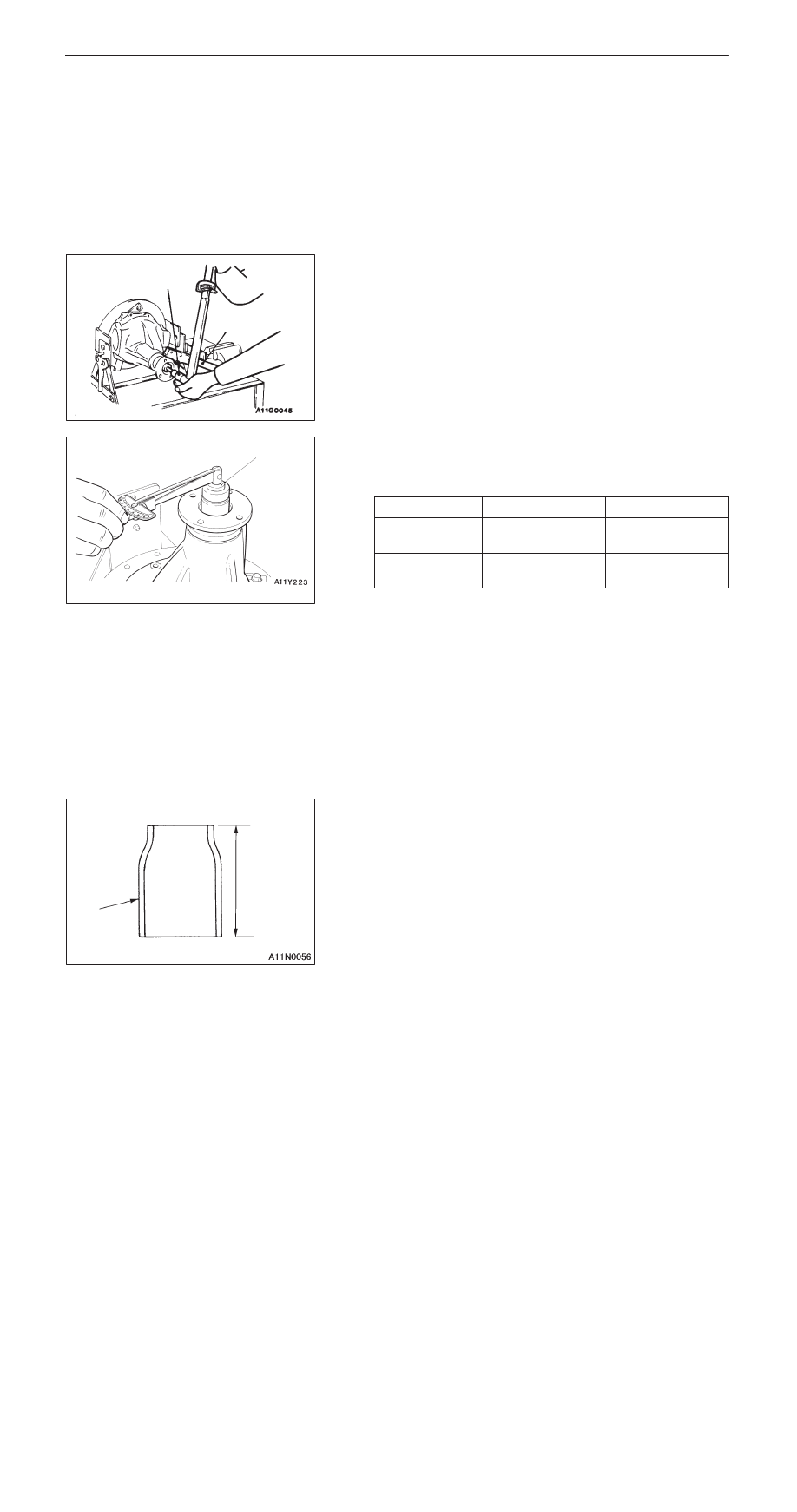

Adjust the drive pinion rotation torque by using the following

procedure:

1.

Insert the drive pinion into the gear carrier, and then install

the drive pinion spacer, the drive pinion rear shim, the

drive pinion rear bearing inner race, and the companion

flange in that order.

NOTE

Do not install the oil seal.

2.

Use the special tool to hold companion flange, and then

tighten the self-locking nut to the specified torque.

3.

Measure the drive pinion rotation torque (without the oil

seal) by using the special tool.

Standard value:

Bearing division

Bearing lubrication

Rotation torque Nm

New

None (With

anti-rust agent)

0.88 – 1.17*

1

0.29 – 0.49*

2

New/reused

Gear oil applied

0.39 – 0.49*

1

0.147 – 0.245*

2

NOTE

*

1

: A/T

*

2

: M/T

4.

If the drive pinion rotation torque is not within the range

of the standard value, adjust it by replacing the drive

pinion rear shim(s) or the drive pinion spacer.

NOTE

When selecting the drive pinion rear shims, if the number

of shims is large, reduce the number of shims to a minimum

by selecting the drive pinion spacers. Also, select the

drive pinion spacer from the following two types.

186 Nm

MB990850

MB990326

Identification

colour

A