Mitsubishi Pajero Pinin. Manual - part 201

FRONT AXLE

–

Drive Shaft

26-23

3.

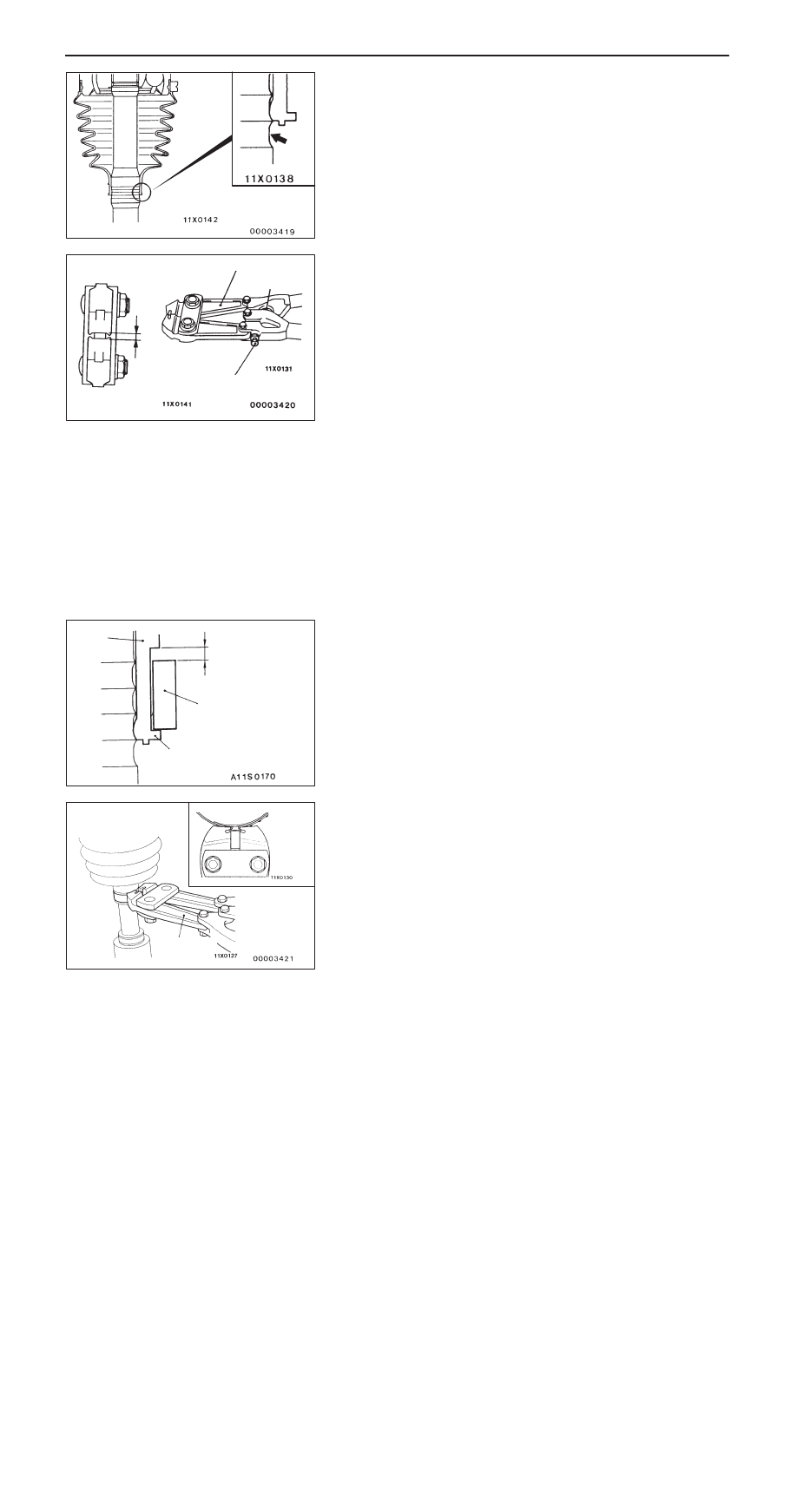

Position the plastic boot small end so that one drive shaft

groove is visible.

4.

Turn the adjusting bolt of the special tool so that the

opening distance (W) meets the standard value.

Standard value (W):

2.9

mm

<More than 2.9

mm>

Tighten the adjusting bolt.

<Less than 2.9

mm>

Loosen the adjusting bolt

NOTE

(1) Turning the adjusting bolt changes the opening

distance (W) by approx. 0.7 mm.

(2) Do not turn the adjusting bolt more than one turn.

5.

Butt the boot band (small) against the boot end projection

so that a certain clearance (A) is obtained.

6.

Use the special tool to crimp the boot band (small).

Caution

(1) Secure the drive shaft in an upright position and

clamp the part of the B.J. boot band to be crimped

securely in the jaws of the special tool.

(2) Crimp the B.J. boot band until the special tool

stopper closes.

(W)

MB991561

Stopper

Adjusting bolt

Boot

Boot band (small)

Projection

A

MB991561