Mitsubishi Pajero Pinin. Manual - part 164

ENGINE AND EMISSION CONTROL –

Engine Control System

ENGINE AND EMISSION CONTROL –

Engine Control System

17-3

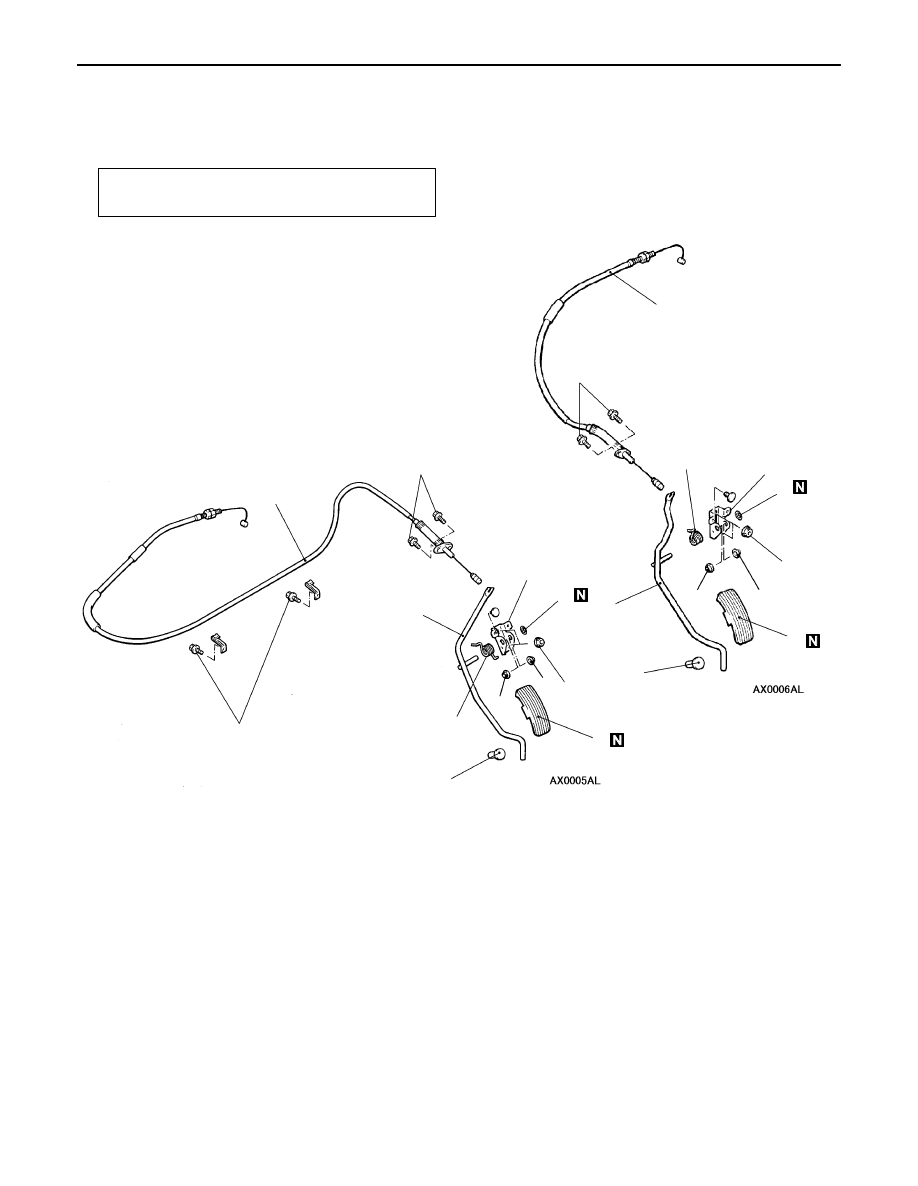

ACCELERATOR CABLE AND PEDAL

REMOVAL AND INSTALLATION

<4G9-MPI>

Post-installation Operation

Accelerator Cable Adjustment (Refer to P.17-2.)

1

2

3

2

4

<L.H. drive vehicles>

<R.H. drive vehicles>

8

6

5

7

5

3

4

6

7

8

1

5.0

±

1.0

N

·

m

6

6

4

5.0

±

1.0

N

·

m

5.0

±

1.0

N

·

m

12

±

2

N

·

m

12

±

2

N

·

m

Removal steps

1. Accelerator cable

2. Push-on spring nut

3. Accelerator arm assembly

4. Spring

5. Accelerator pedal bracket

6. Bushing

7. Pedal pad

"

A

A

8. Accelerator pedal stopper

INSTALLATION SERVICE POINT

A

A

"

ACCELERATOR PEDAL STOPPER INSTALLATION

Heat up the claw of the accelerator pedal pad with a drier

and etc. before installation.

NOTE

Apply some soapsuds to the claw to facilitate installation if

there is any difficulty.