Mitsubishi Pajero Pinin. Manual - part 160

ENGINE AND EMISSION CONTROL –

Emission Control System

17-9

POSITIVE CRANKCASE VENTILATION SYSTEM

CHECK

1.

Remove the ventilation hose from the PCV valve.

2.

Remove the PCV valve from the rocker cover.

3.

Reinstall the PCV valve at the ventilation hose.

4.

Start the engine and run at idle.

5.

Place a finger at the opening of the PCV valve and check

that vacuum of the intake manifold is felt.

NOTE

At this moment, the plunger in the PCV valve moves back

and forth.

6.

If vacuum is not felt, clean the PCV valve or replace it.

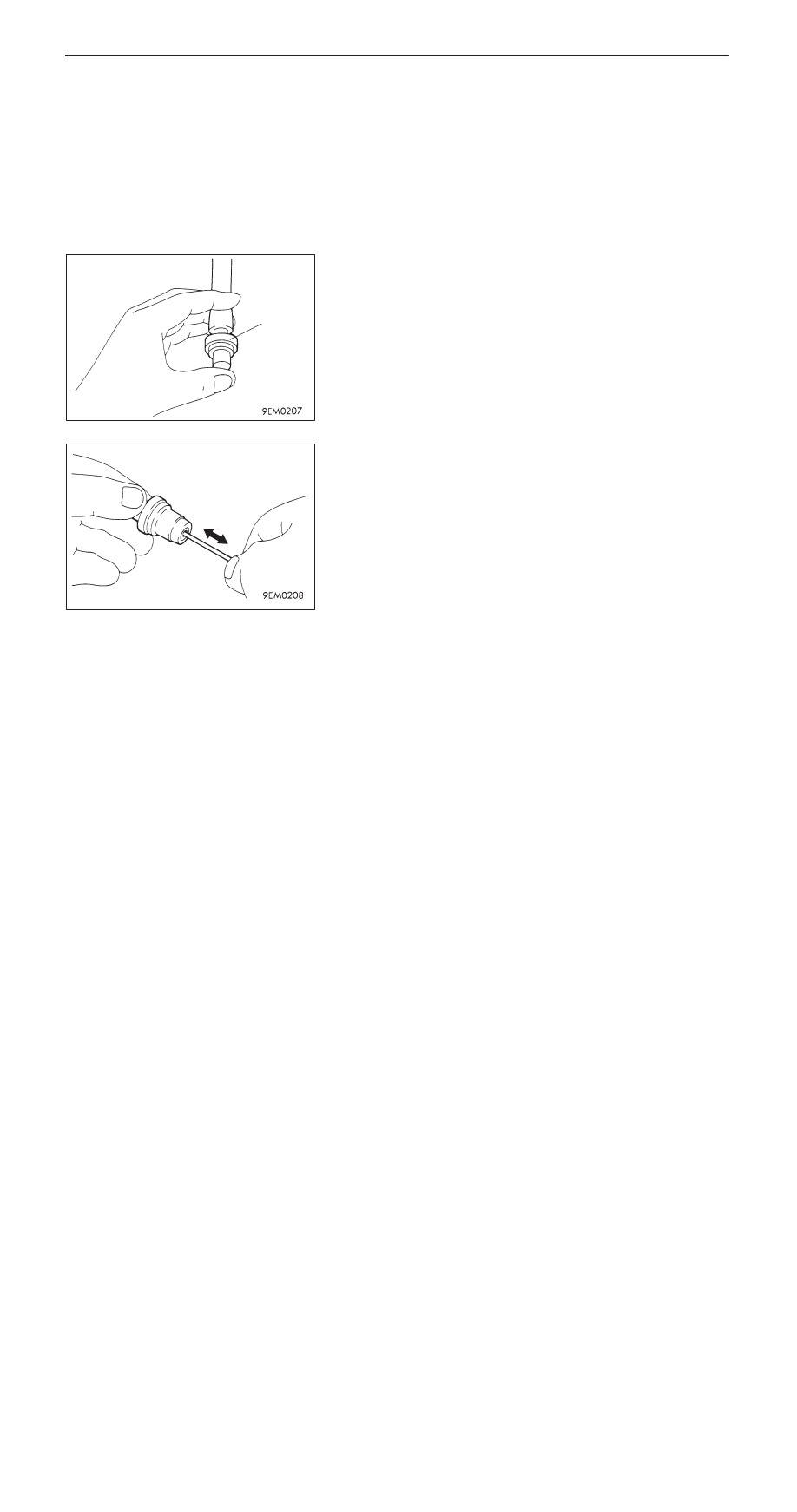

PCV VALVE CHECK

1.

Insert a thin rod into the PCV valve from the side shown

in the illustration (rocker cover installation side), and move

the rod back and forth to check that the plunger moves.

2.

If the plunger does not move, there is clogging in the

PCV valve. In this case, clean or replace the PCV valve.

PCV valve