Mitsubishi Pajero Pinin. Manual - part 150

ENGINE ELECTRICAL –

Ignition System

16-30

SPARK PLUG CHECK AND CLEANING

CAUTION

1.

Do not adjust the gap for iridium plugs.

2.

The iridium tips may become damaged when iridium

plugs are cleaned. Accordingly, if the plugs are sooty

and need to be cleaned, use a plug cleaner in order

to protect the terminals, and do not clean for more

than 20 seconds. Tools such as wire brushes must

never be used.

3.

The terminals of iridium plugs may become blackened,

even when the plugs are functioning normally.

However, the carbon which is deposited onto these

plugs burns off more easily than for conventional

spark plugs, so such blackening is not normally a

problem. Measure the insulation resistance of the

spark plug to judge if the plug is still usable or not.

(1) Check the plug gap, and replace the plug if the gap is

greater than the limit value.

Standard Valve : 0.5 – 0.6 mm

Limit : 0.75 mm

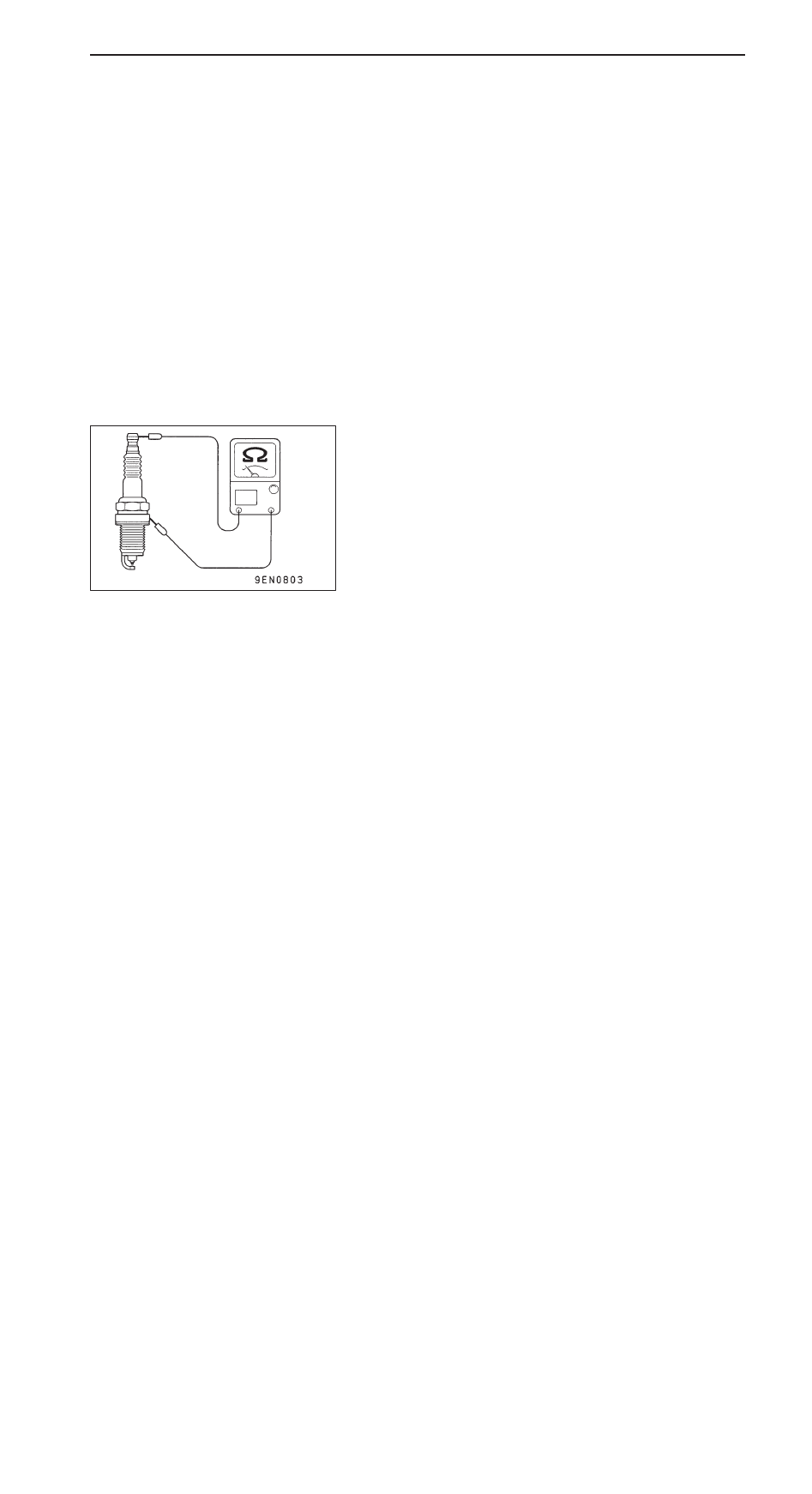

(2) Measure the insulation resistance of the spark plug, and

replace the plug if the resistance is below the limit value.

Limit : 1 M

Ω

CAMSHAFT POSITION SENSOR CHECK

Refer to GROUP 13A – Troubleshooting.

CRANK ANGLE SENSOR CHECK

Refer to GROUP 13A – Troubleshooting.

DETONATION SENSOR CHECK

Check the detonation sensor circuit if self-diagnosis code,

No. 31 is shown.

NOTE

For information concerning the self-diagnosis codes, refer to

GROUP 13A – Troubleshooting .