Mitsubishi Pajero Pinin. Manual - part 129

MPI <4G9> –

On-vehicle Service

13C-102

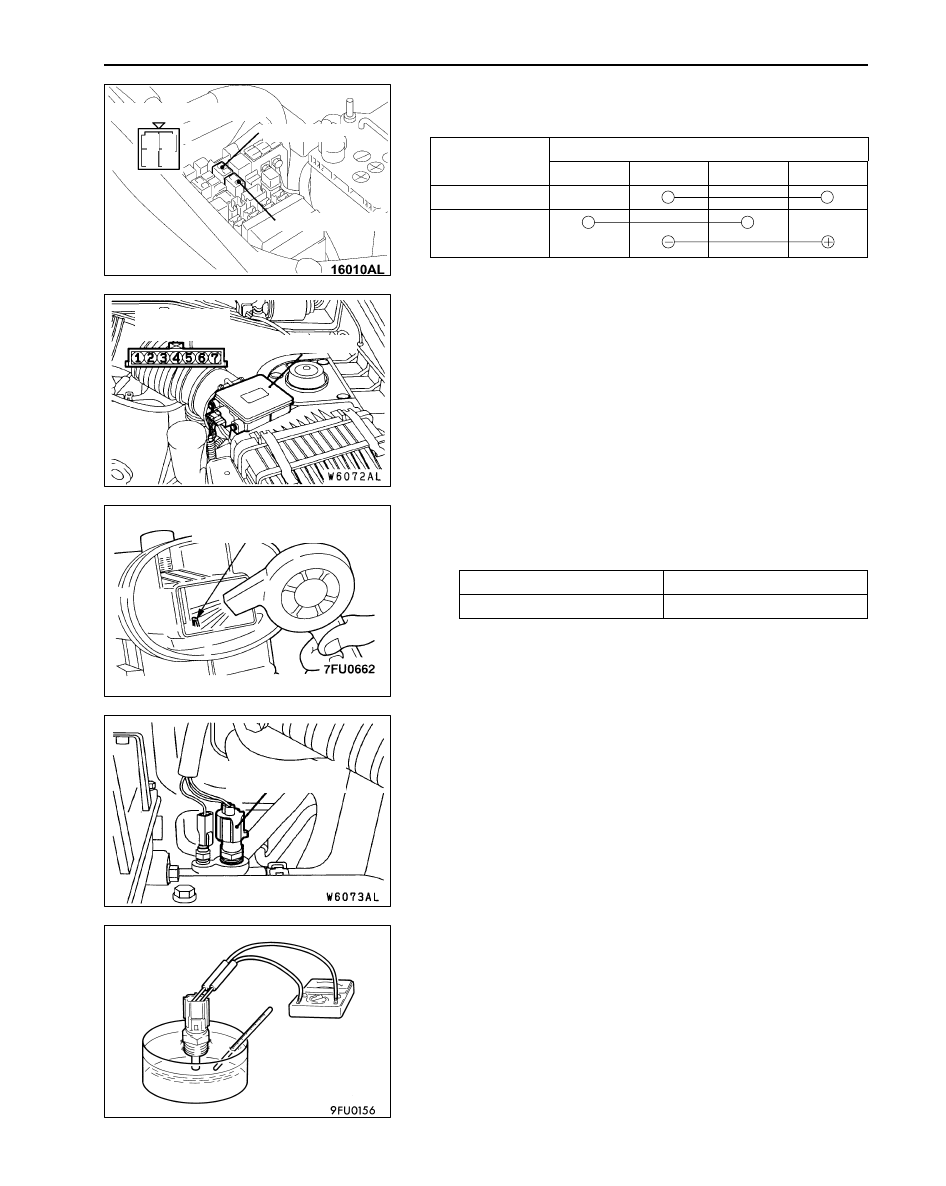

CONTROL RELAY AND FUEL PUMP RELAY

CONTINUITY CHECK

Battery voltage

Terminal No.

y

g

1

2

3

4

Not supplied

Supplied

INTAKE AIR TEMPERATURE SENSOR CHECK

1.

Disconnect the air flow sensor connector.

2.

Measure resistance between terminals 5 and 6.

Standard value:

13 – 17 k

Ω

(at –20

_

C)

5.7 – 6.7 k

Ω

(at 0

_

C)

2.3 – 3.0 k

Ω

(at 20

_

C)

1.0 – 1.5 k

Ω

(at 40

_

C)

0.56 – 0.76 k

Ω

(at 60

_

C)

0.30 – 0.42 k

Ω

(at 80

_

C)

3.

Measure resistance while heating the sensor using a hair

drier.

Normal condition:

Temperature (

_

C)

Resistance (k

Ω

)

Higher

Smaller

4.

If the value deviates from the standard value or the

resistance remains unchanged, replace the air flow sensor

assembly.

ENGINE COOLANT TEMPERATURE SENSOR

CHECK

Caution

Be careful not to touch the connector (resin section) with

the tool when removing and installing.

1.

Remove the engine coolant temperature sensor.

2.

With temperature sensing portion of engine coolant

temperature sensor immersed in hot water, check

resistance.

1

4

3

2

Equipment side connector

Control relay

Fuel pump relay

Equipment side

connector

Air flow sensor

Intake air temperature

sensor

Engine coolant

temperature sensor