Mitsubishi Pajero Pinin. Manual - part 118

MPI <4G9> –

Troubleshooting

13C-58

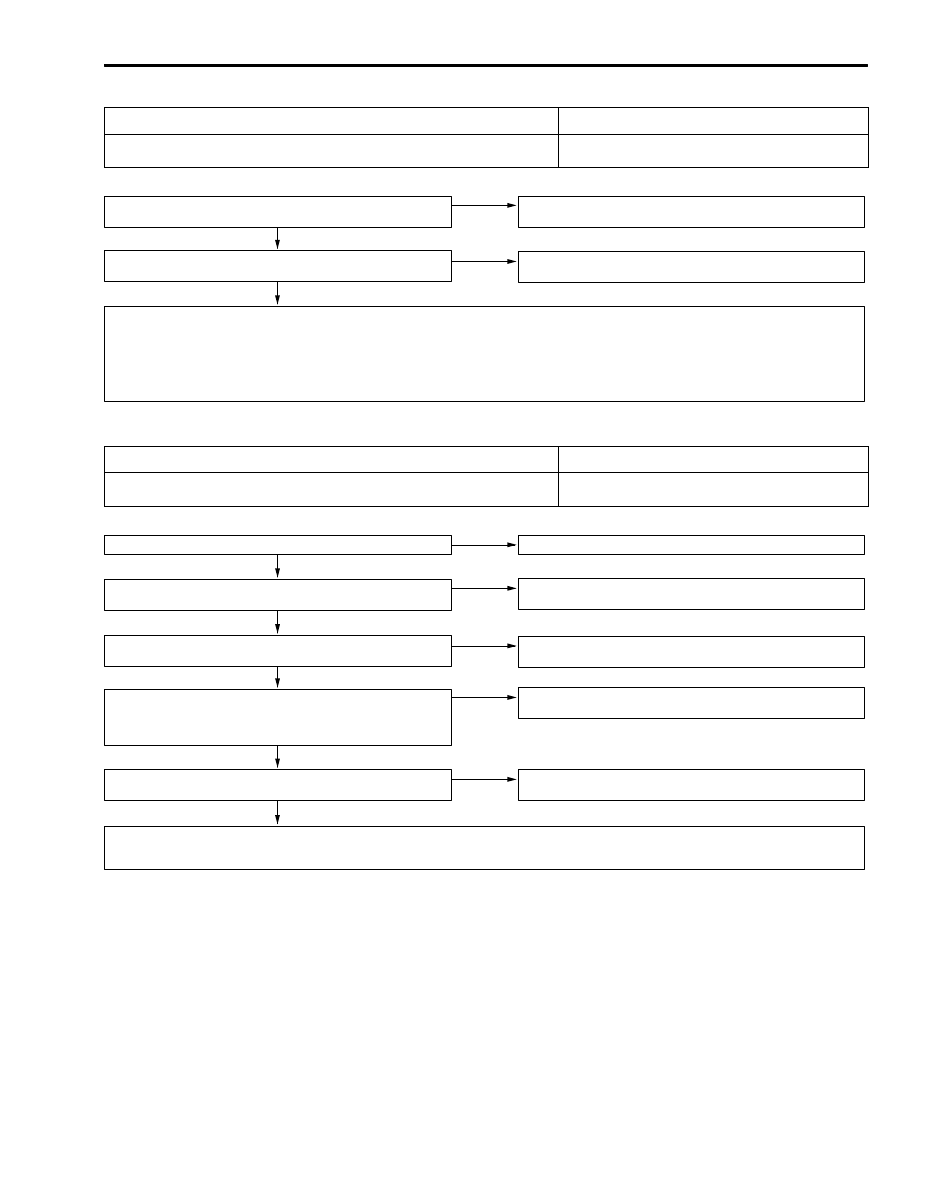

INSPECTION PROCEDURE 13

The engine stalls when starting the car. (Pass out)

Probable cause

In cases such as the above, the cause is probably misfiring due to a weak spark,

or an inappropriate air/fuel mixture when the accelerator pedal is depressed.

D

Drawing air into intake system

D

Malfunction of the ignition system

OK

Check the following items.

D

Check the ignition coil, spark plugs, spark plug cables.

D

Check if air was drawn into the intake system.

Broken intake manifold gasket

Broken or disconnected vacuum hose

Improper operation of the PCV valve

Broken air intake hose

NG

Check the EGR control solenoid valve system. (Refer to P.13C-36,

INSPECTION PROCEDURE FOR DIAGNOSIS CODE P0403.)

No

MUT-

II

Actuator test

10 EGR control solenoid valve (Refer to P.13C-79.)

MUT-

II

Self-Diag code

Are diagnosis codes displayed?

Yes

Refer to P.13C-12, INSPECTION CHART FOR DIAGNOSIS

CODES.

INSPECTION PROCEDURE 14

The engine stalls when decelerating.

Probable cause

In cases such as the above, the cause is probably that the intake air volume is

insufficient due to a defective idle speed control (ISC) servo system.

D

Malfunction of the ISC system

OK

Check the following items.

D

Check the ignition coil, spark plugs, spark plug cables.

D

Clean the throttle valve area.

NG

Check the EGR control solenoid valve system. (Refer to P.13C-36,

INSPECTION PROCEDURE FOR DIAGNOSIS CODE P0403.)

No

MUT-

II

Actuator test

10 EGR control solenoid valve (Refer to P.13C-79.)

Yes

Check the vehicle speed sensor system. (Refer to P.13C-40, IN-

SPECTION PROCEDURE FOR DIAGNOSIS CODE P0500.)

OK

MUT-

II

Data list

45 ISC servo position

D

Is the idle speed control (ISC) servo position drops to 0 –

2 steps when decelerating (engine r/min less than 1,000)?

NG

Check the throttle position sensor system. (Refer to P.13C-22,

INSPECTION PROCEDURE FOR DIAGNOSIS CODE P0120.)

OK

MUT-

II

Data list

14 Throttle position sensor (Refer to P.13C-75.)

Yes

Refer to P.13C-12, INSPECTION CHART FOR DIAGNOSIS

CODES.

No

MUT-

II

Self-Diag code

Are diagnosis codes displayed?

Were the battery terminals disconnected?

Yes

After warming-up, let the engine run at idling for 10 minutes.