Mitsubishi Pajero Pinin. Manual - part 111

MPI <4G9> –

Troubleshooting

13C-30

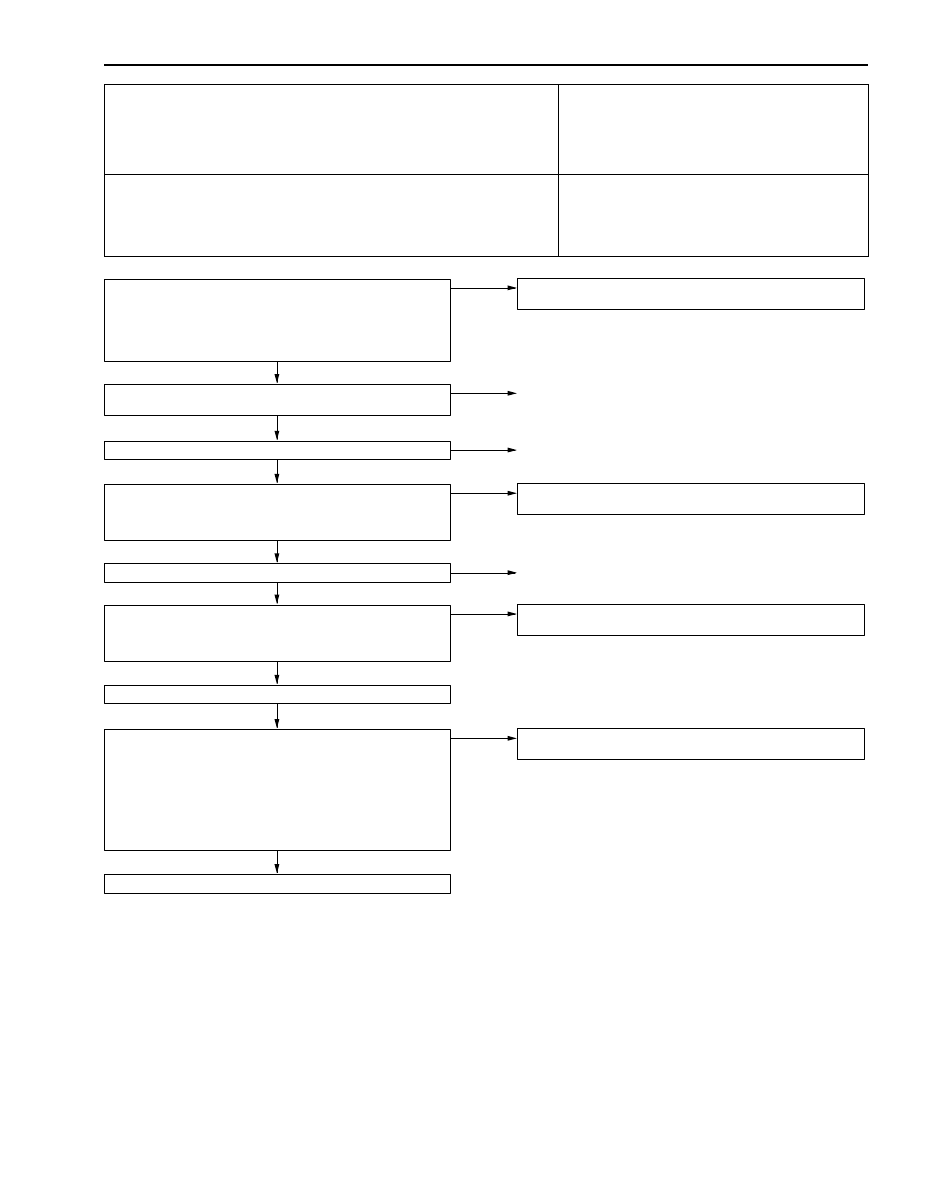

Code No. P0201 No. 1 injector system

Code No. P0202 No. 2 injector system

Code No. P0203 No. 3 injector system

Code No. P0204 No. 4 injector system

Probable cause

Range of Check

D

Engine speed is approx. 50 – 1,000 r/min

D

The throttle position sensor output voltage is 1.15 V or less.

D

Actuator test by MUT-

II

is not carried out.

Set Conditions

D

Surge voltage of injector coil is not detected for 4 seconds.

D

Malfunction of the injector

D

Improper connector contact, open circuit or short-cir-

cuited harness wire of the injector circuit

D

Malfunction of engine-ECU

NG

Replace the engine-ECU.

NG

Use an analyzer to measure the signal waveform at injector

connector A-61, A-62, A-63, A-64.

D

Use a test harness (MB991348) to connect the connector, and

measure at the pick-up harness side.

D

Engine: Idling

D

The voltage between terminal 2 and earth

OK: A normal waveform should be displayed as de-

scribed on P.13C-87 (INSPECTION PROCEDURE

USING AN ANALYZER).

OK

Intermittent malfunction

(Refer to GROUP 00 – Points to Note for Intermittent Malfunctions.)

OK

Check the trouble symptoms.

OK

Measure at the engine-ECU connector C-87.

D

Disconnect the connector, and measure at the harness side.

D

Voltage between 1, 2, 14, 15 and earth (Ignition switch: ON)

OK: System voltage

NG

Check the harness wire between the engine-ECU and the injector

connector, and repair if necessary.

OK

Check the following connector: C-87

NG

Repair

OK

Measure at the injector connector A-61, A-62, A-63, A-64.

D

Disconnect the connector, and measure at the harness side.

D

Voltage between 1 and earth (Ignition switch: ON)

OK: System voltage

NG

Check the harness wire between the engine control relay and the

injector connector, and repair if necessary.

OK

Check the injector. (Refer to P.13C-106.)

NG

Replace

NG

Check the following connectors:

A-61, A-62, A-63, A-64

NG

Repair

MUT-

II

Actuator Test

01 No. 1 injector

02 No. 2 injector

03 No. 3 injector

04 No. 4 injector

OK: The idling condition should change

OK

Intermittent malfunction

(Refer to GROUP 00 – Points to Note for Intermittent Malfunctions.)