Mitsubishi Pajero Pinin. Manual - part 55

GDI –

Troubleshooting

13A-86

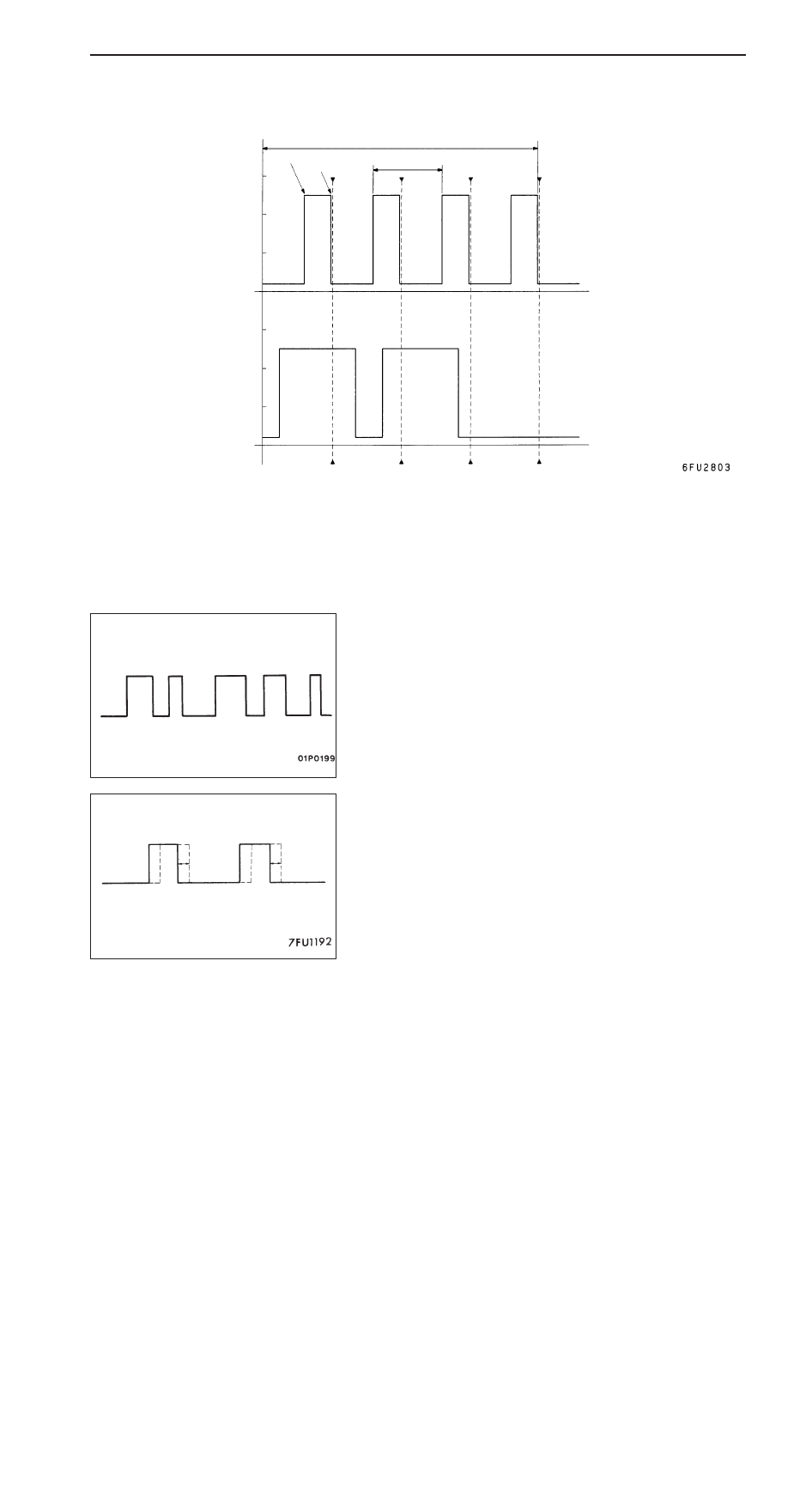

Standard wave pattern

Crank angle

sensor output

wave pattern

(V)

75

_

BTDC

2 engine revolutions

(1 camshaft revolution)

5

_

BTDC

The time (cycle time) T is

reduced when the engine

speed increases

0

Camshaft posi-

tion sensor out-

put wave pat-

tern

TDC: Top dead centre

No. 1

TDC

No. 3 TDC

No.

4

TDC

No. 2

TDC

Time

0

T

4

4

Wave Pattern Observation Points

Check that cycle time T becomes shorter when the engine speed increases.

Examples of Abnormal Wave Patterns

D

Example 1

Cause of problem

Sensor interface malfunction

Wave pattern characteristics

Rectangular wave pattern is output even when the engine

is not started.

D

Example 2

Cause of problem

Loose timing belt

Abnormality in sensor disk

Wave pattern characteristics

Wave pattern is displaced to the left or right.