Mitsubishi Space Star. Manual - part 47

GDI –

Troubleshooting

13A-115

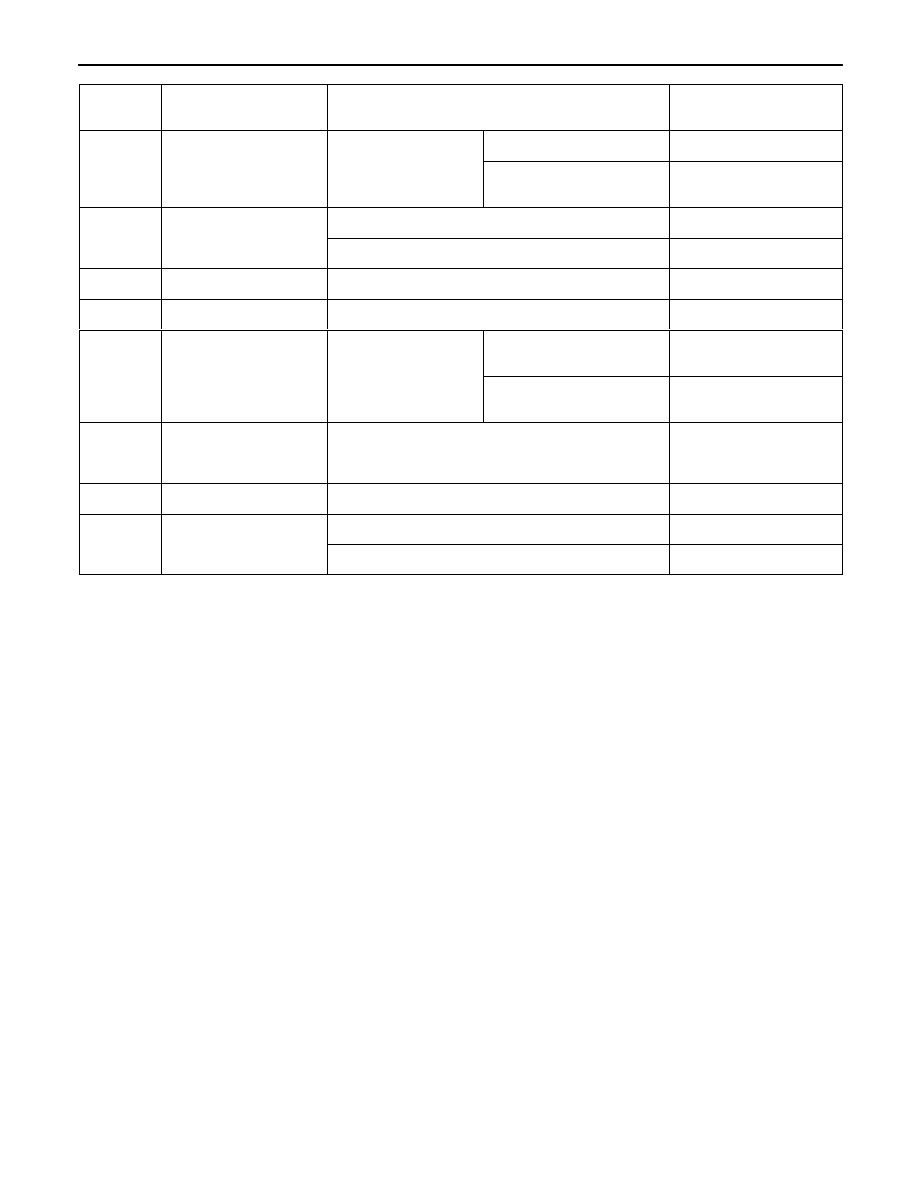

Terminal

No.

Normal condition

Check condition (Engine condition)

Check item

83

A/C switch 1

Engine: Idling

A/C switch: OFF

0 – 3 V

A/C switch: ON (Compres-

sor is operating)

System voltage

86

Small lamp switch

Lighting switch: OFF

0 – 3 V

Lighting switch: Tail light position

System voltage

87

Sensor applied voltage

Ignition switch: ON

4.5 – 5.5 V

93

Fuel pressure sensor

Engine: Idling

0.3 – 4.7 V

95

Accelerator pedal posi-

tion sensor (1st chan-

nel)

Ignition switch: ON

Release the accelerator

pedal.

0.985 – 1.085 V

nel)

Depress the accelerator

pedal fully.

4.0 V or higher

96

Brake vacuum sensor

Engine: Stop the engine from idle speed, turn the

ignition switch ON, and then depress the brake

pedal several times.

Voltage increases

98

Ignition switch-IG

Ignition switch: ON

System voltage

123

Stop lamp switch

Depress the brake pedal.

System voltage

Release the brake pedal.

0 – 3 V

CHECK CHART FOR RESISTANCE AND CONTINUITY

BETWEEN TERMINALS

1.

Turn the ignition switch to OFF.

2.

Disconnect the engine-A/T-ECU connector.

3.

Measure the resistance and check for continuity between

the terminals of the engine-A/T-ECU harness-side

connector while referring to the check chart.

NOTE

(1) When measuring resistance and checking continuity,

a harness for checking contact pin pressure should

be used instead of inserting a test probe.

(2) Checking need not be carried out in the order given

in the chart.

Caution

If the terminals that should be checked are mistaken,

or if connector terminals are not correctly shorted

to earth, damage may be caused to the vehicle wiring,

sensors, engine-A/T-ECU and/or ohmmeter.

Be careful to prevent this!

4.

If the ohmmeter shows any deviation from the standard

value, check the corresponding sensor, actuator and

related electrical wiring, and then repair or replace.

5.

After repair or replacement, recheck with the ohmmeter

to confirm that the repair or replacement has corrected

the problem.