Mitsubishi Lancer (4A9 engine). Manual - part 115

HEADLAMP

CHASSIS ELECTRICAL

54A-122

STEP 2. M.U.T.-III data list

Using the ETACS-ECU service data, check the sig-

nals related to the illumination of turn-signal lamp.

• Turn the ignition switch to the ON position.

• Turn the turn-signal lamp switch to the left posi-

tion.

• Turn the turn-signal lamp switch to the right posi-

tion.

OK: Normal conditions are displayed for all

the items.

Q: Is the check result normal?

Normal conditions are displayed for all the items. :

Go to Step 3.

Normal condition is not displayed for item No. 254.

:

Troubleshoot the ETACS-ECU. Refer to

Inspection Procedure 2 "The ignition switch

(IG1) signal is not received" .

Normal condition is not displayed for item No. 343

or 344. :

Troubleshoot the ETACS-ECU. Refer to

Inspection Procedure 11 "The column

switch signal is not received" .

STEP 3. Retest the system

Check that the turn-signal lamps illuminate.

Q: Is the check result normal?

YES :

The trouble can be an intermittent

malfunction (Refer to GROUP 00

− How to

use Troubleshooting/inspection Service

Points

− How to Cope with Intermittent

Malfunction ).

NO :

Replace the ETACS-ECU.

Inspection Procedure 11: The comfort flashing function does not work normally.

CAUTION

Whenever the ECU is replaced, ensure that the

power supply circuit, the earth circuit and the

communication circuit are normal.

COMMENTS ON TROUBLE SYMPTOM

If the comfort flashing function does not work nor-

mally, the turn-signal lamp switch input circuit(s) and

ETACS-ECU may have a problem.

PROBABLE CAUSES

• Malfunction of column switch

• Malfunction of the ETACS-ECU

• Damaged harness wires and connectors

DIAGNOSIS PROCEDURE

STEP 1. ETACS-ECU customise function check

Use the ETACS-ECU customise function to check

that the "Comfort flasher" is set to "Enable."

Q: Is the check result normal?

YES :

Go to Step 2.

NO :

Use the ETACS-ECU customise function to

set the "Comfort flasher" to "Enable" (Refer

to ).

STEP 2. M.U.T.-III diagnosis code

Check if diagnosis code is set to the ETACS-ECU.

Q: Is the diagnosis code set?

YES :

Troubleshoot the ETACS-ECU. Refer to .

NO :

Go to Step 3.

STEP 3. Check that the turn-signal lamps

operate.

Check that the turn-signal lamps work normally when

the ignition switch is in the ON position.

Q: Is the check result normal?

YES :

Go to Step 4.

NO :

Refer to Inspection Procedure 10 "None of

the turn-signal lamps illuminate" .

STEP 4. Retest the system

Check that the comfort flashing function works nor-

mally.

Q: Is the check result normal?

YES :

The trouble can be an intermittent

malfunction (Refer to GROUP 00

− How to

use Troubleshooting/inspection Service

Points

− How to Cope with Intermittent

Malfunction ).

NO :

Replace the ETACS-ECU.

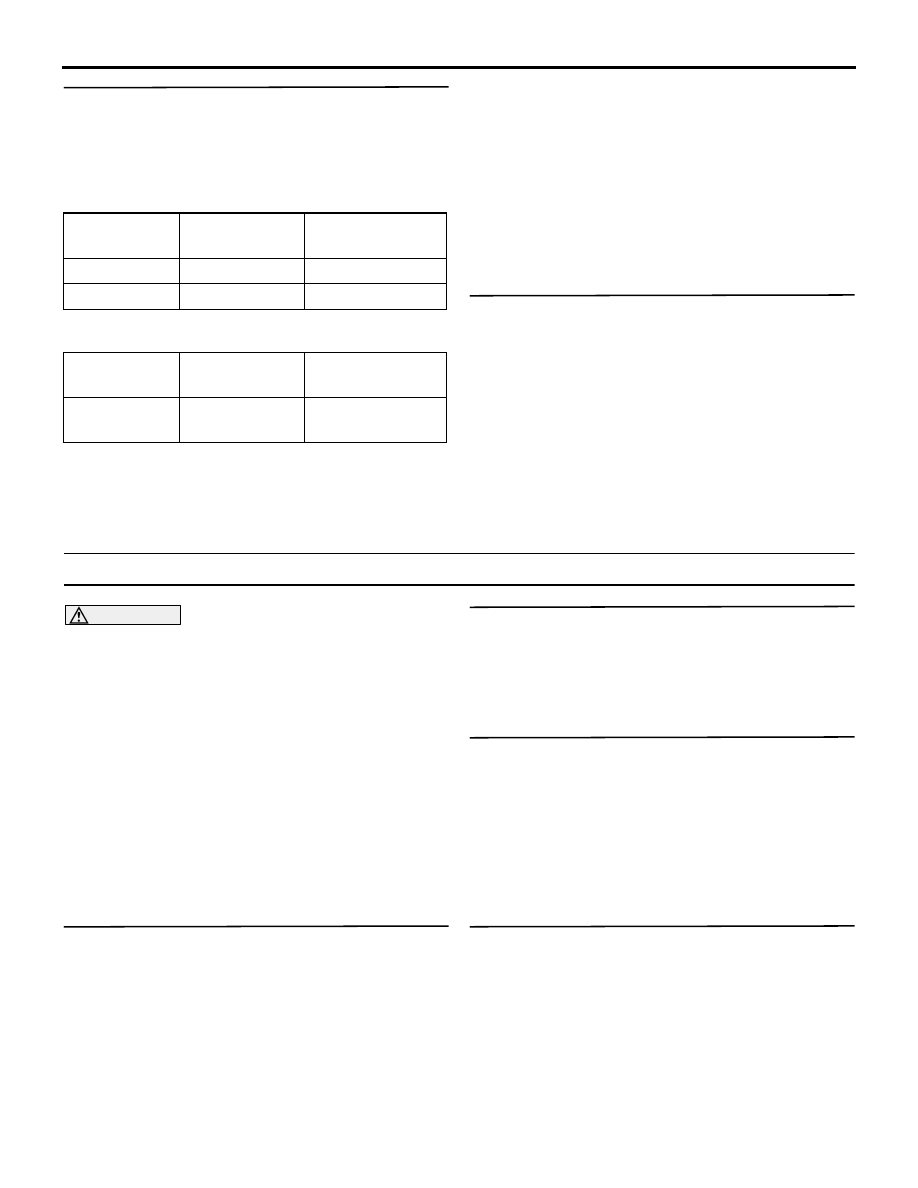

Item No.

Item name

Normal

condition

Item 254

IG voltage

System voltage

Item 343

Turn switch left ON

Item No.

Item name

Normal

condition

Item 344

Turn switch

right

ON