Mitsubishi Lancer (4A9 engine). Manual - part 99

COMBINATION METER

CHASSIS ELECTRICAL

54A-58

Inspection Procedure 9: The multi information display screen cannot be changed with the operation

of the meter information switch.

CAUTION

Before replacing the combination meter, be sure

to check that the power supply circuit, earth cir-

cuit, and communication circuit are normal.

COMMENTS ON TROUBLE SYMPTOM

When the signal from the meter information switch is

received, the combination meter switches the multi

information display screen. If the multi information

display screen does not switch normally, the meter

information switch, wiring harness, connector(s), or

combination meter may have a problem.

PROBABLE CAUSES

• Malfunction of meter information switch

• Malfunction of combination meter

• Damaged harness wires and connectors

DIAGNOSIS PROCEDURE

STEP 1. M.U.T.-III diagnosis code

Check if diagnosis code is set to the combination

meter.

Q: Is the diagnosis code set?

YES :

Refer to .

NO :

Go to Step 2.

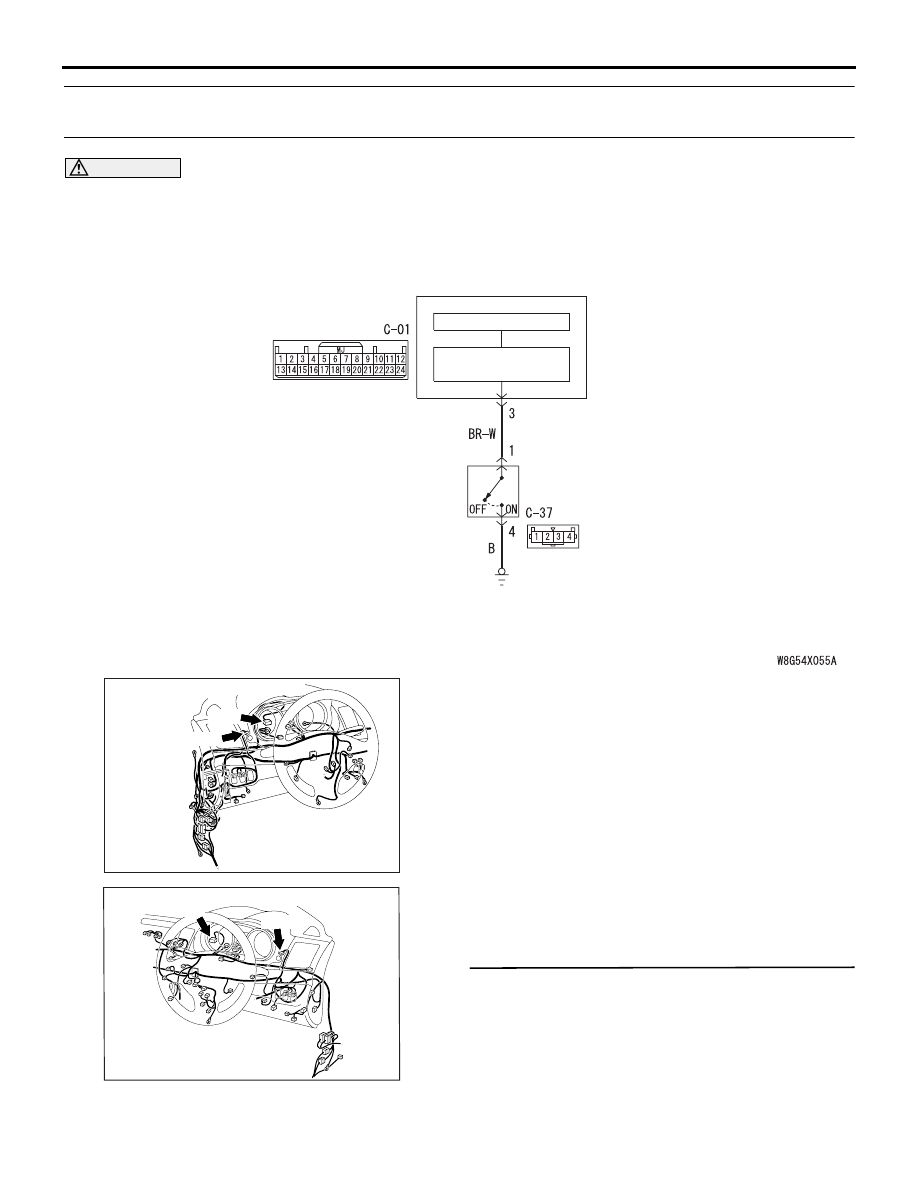

Meter Information Switch Circuit

INTERFACE

CIRCUIT

COMBINATION

METER

CPU

METER

INFORMATION

SWITCH

Wire colour code

B : Black LG : Light green G : Green L : Blue W : White Y : Yellow SB : Sky blue

BR : Brown O : Orange GR : Grey R : Red P : Pink V : Violet PU : Purple SI : Silver

AC701093 BB

Connectors: C-01, C-37 <LHD>

C-01

C-37

AC701122 BQ

Connectors: C-01, C-37 <RHD>

C-01

C-37