Mitsubishi Lancer (4A9 engine). Manual - part 88

BATTERY

CHASSIS ELECTRICAL

54A-14

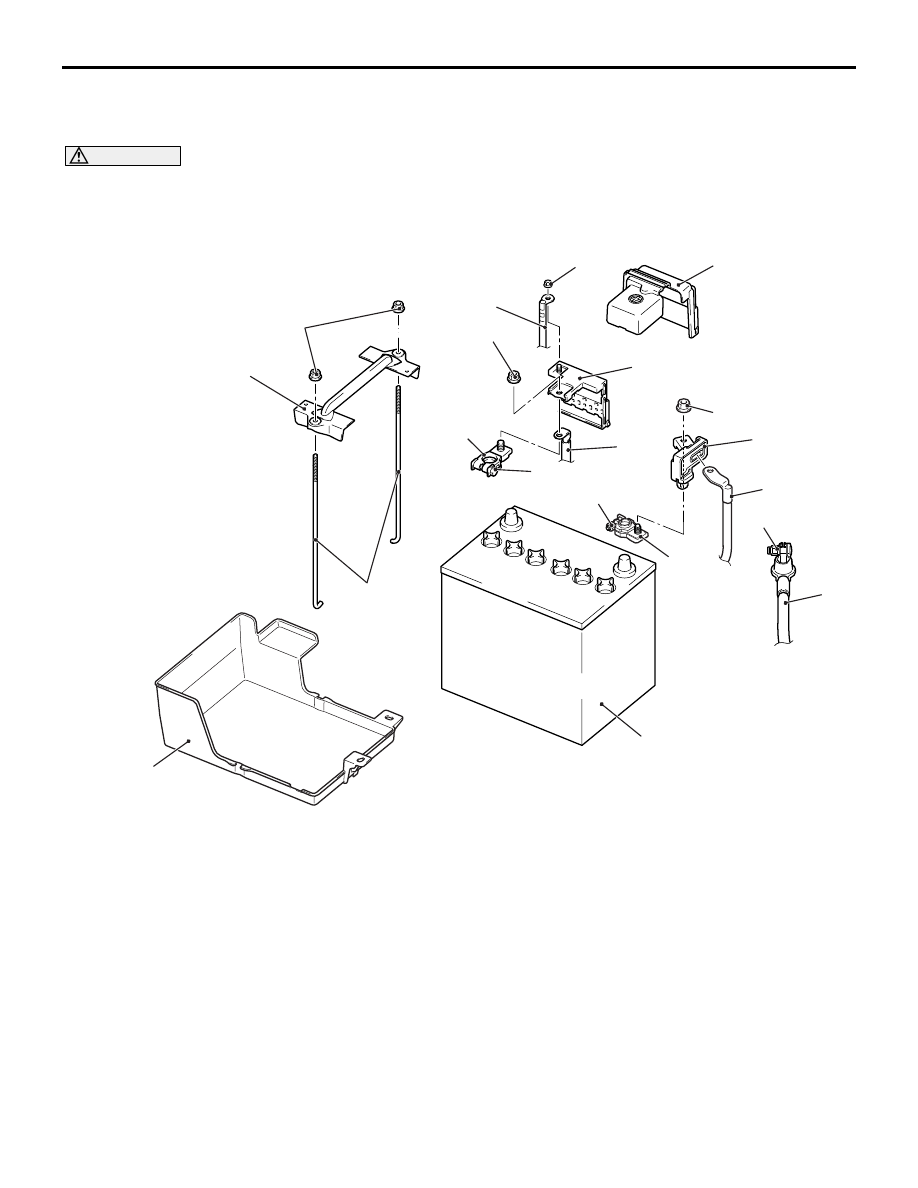

REMOVAL AND INSTALLATION

M1541001301506

<1600, 1800-PETROL, 2000>

CAUTION

If the battery current sensor or engine-ECU is replaced, make the battery current sensor learn the

zero point. (Refer to GROUP 00, Precautions Before Service

− Battery Current Sensor Calibration.)

<Low CO

2

specification, FFV>

ACB01849

AB

2

5

6

7

4

9

12

11

8.5 ± 1.5 N·m

12 ± 2 N·m

4.0 ± 1.0 N·m

5.0 ± 1.0 N·m

6.0 ± 2.0 N·m

10

8

1

2

3

5.0 ± 1.0 N·m

<Low CO2 specification, FFV>

<Except Low CO2

specification, FFV>

12 ± 2 N·m

Removal steps

1.

Battery current sensor <Low CO

2

specification, FFV>

2.

Connection of the battery harness

[negative battery terminal]

3.

Battery terminal assembly [negative

battery terminal] <Low CO

2

specification, FFV>

•

Air cleaner intake duct (Refer to GROUP

15

− Air Cleaner <1800-PETROL,

2000> or <1600>).

4.

Fusible link box cover

5.

Connection of the battery harness

[positive battery terminal]

6.

Connection of the fusible link box

7.

Connection of the battery harness

[positive battery terminal]

8.

Battery terminal assembly [positive

battery terminal]

9.

Battery holder

10. Battery bolt

11. Battery

12. Battery tray

Removal steps (Continued)