Mitsubishi Lancer (4A9 engine). Manual - part 60

TROUBLESHOOTING

ACTIVE STABILITY CONTROL SYSTEM (ASC)

35C-93

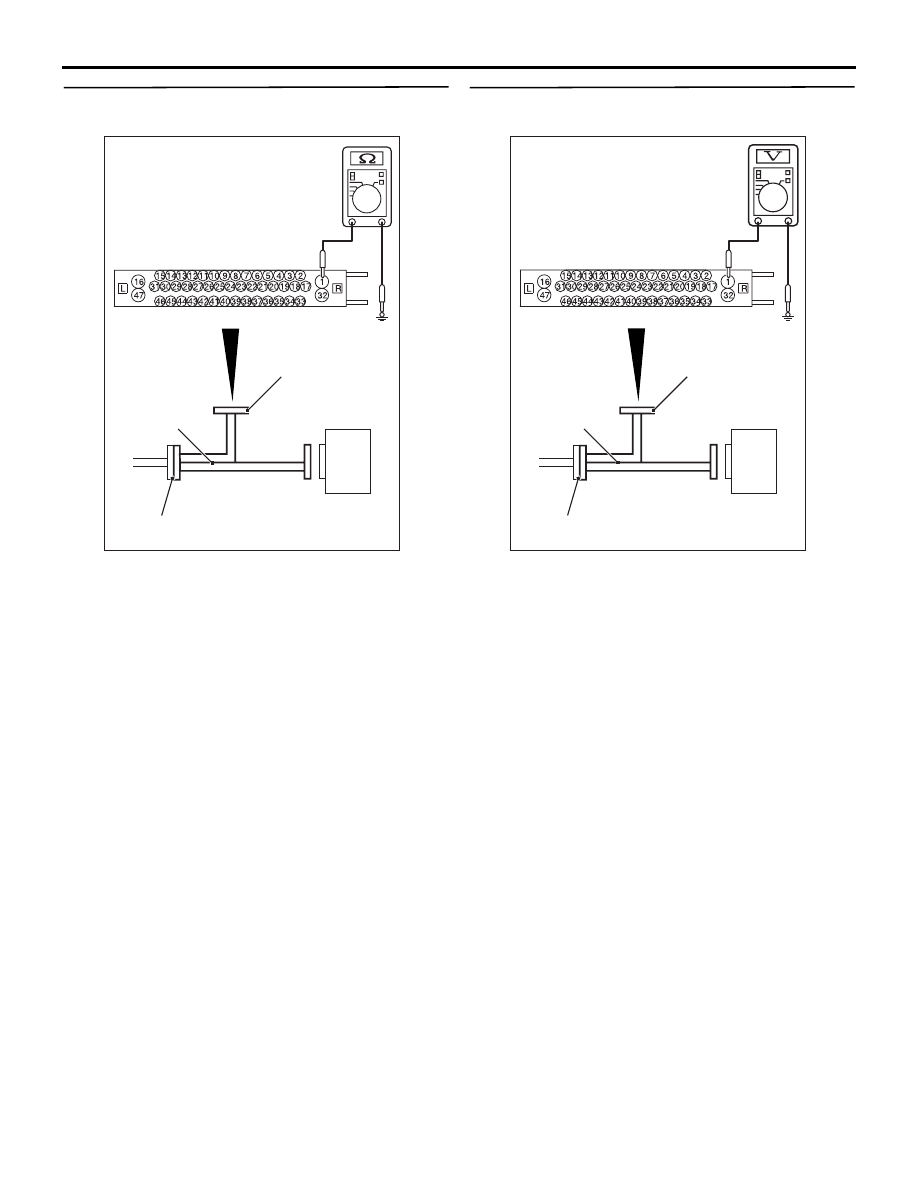

STEP 7. Resistance measurement at A-58 ASC-

ECU connector

AC606869FS

ASC-ECU

MB991997

Check harness

A-58 ASC-ECU

harness connector

(1) Disconnect the ASC-ECU connector, connect

special tool ASC check harness (MB991997) to

the harness-side connector, and then measure

the resistance at the special tool connector side.

NOTE: Do not connect the special tool ASC

check harness (MB991997) to ASC-ECU.

(2) Disconnect the fusible link No.26.

(3) Measure the resistance between the terminal

No.1 and the body earth.

OK: No continuity

Q: Is the check result normal?

YES :

Replace the fusible link No.26. Then go to

Step 11.

NO :

The short circuit may be present in the

power supply circuit. Repair the wiring

harness between the A-58 ASC-ECU

connector terminal No.1 and the fusible link

No.26, and then replace the fusible link

No.26. Then go to Step 11.

STEP 8. Voltage measurement at the A-58 ASC-

ECU connector

AC606869DI

ASC-ECU

MB991997

Check harness

A-58 ASC-ECU

harness connector

(1) Disconnect the ASC-ECU connector, connect

special tool ASC check harness (MB991997) to

the harness-side connector, and then measure

the voltage at the special tool connector side.

NOTE: Do not connect the special tool ASC

check harness (MB991997) to ASC-ECU.

(2) Measure the voltage between the terminal No.1

and the body earth.

OK: Approximately system voltage

Q: Is the check result normal?

YES :

Go to Step 9.

NO :

The open circuit may be present in the

power supply circuit. Repair the wiring

harness between the A-58 ASC-ECU

connector terminal No.1 and the fusible link

No.26. Then go to Step 11.