Mitsubishi Lancer (4A9 engine). Manual - part 31

OIL PAN

ENGINE MECHANICAL <4A9>

11A-38

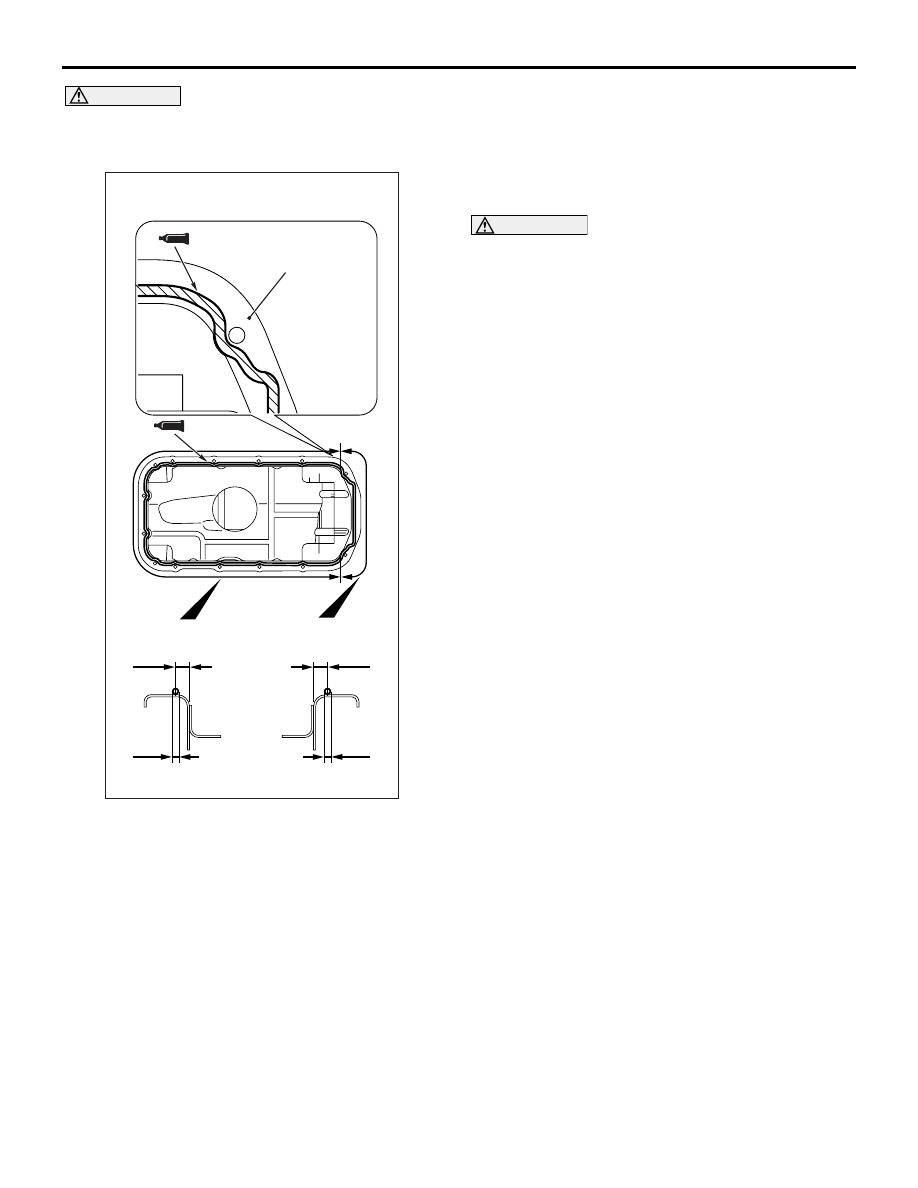

CAUTION

As oil leak is likely to occur at both ends of the

rear side of the engine oil pan, be sure to apply

the specified sealant as shown.

AC403646

AC

5.5 mm

5.5 mm

Engine oil pan

Both engine oil pan rear side edge parts

2 mm

4 mm

2. Apply a bead of the sealant to the cylinder block

mating surface of the engine oil pan as shown.

Specified sealant: ThreBond 1217G or equiv-

alent

NOTE: Install the engine oil pan immediately after

the application of sealant.

CAUTION

After the installation, until a sufficient period of

time (one hour or more) elapses, do not apply the

engine oil or water to the sealant application area

or start the engine.

3. Tighten the engine oil pan mounting bolts to the

specified torque.

Tightening torque: 11

± 3 N⋅m

INSPECTION

M1112002900889

• Check the engine oil pan for cracks.

• Check the engine oil pan sealant-coated surface

for damage and deformation.