Mitsubishi Lancer (4A9 engine). Manual - part 18

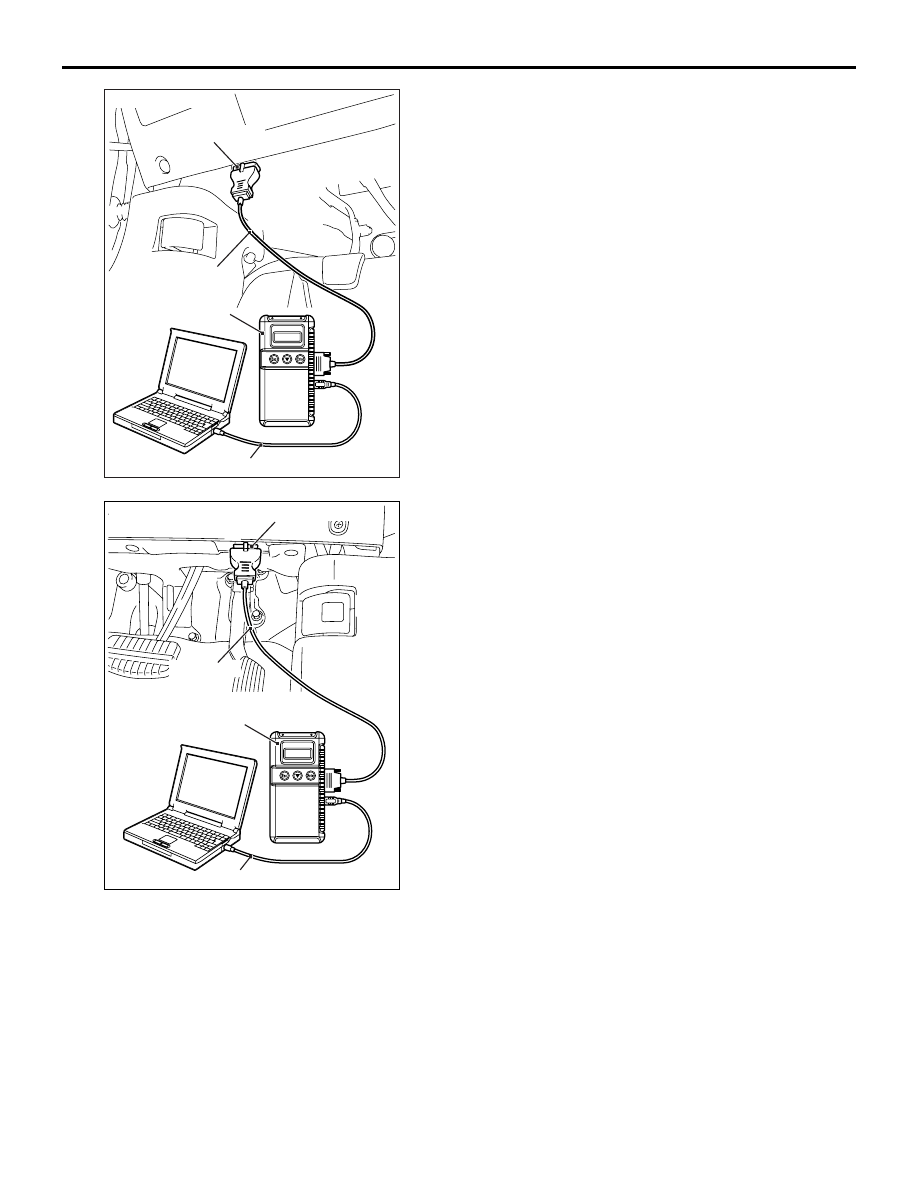

AC608435

MB991827

MB991824

MB991910

AB

Diagnosis connector

<LH drive vehicles>

AC700191

MB991827

MB991824

AB

Diagnosis connector

<RH drive vehicles>

MB991910

PRECAUTIONS BEFORE SERVICE

GENERAL

00-69

4. Connect the M.U.T.-III to the diagnosis connector

(But do not start the engine).

5. Turn the ignition switch to the ON position.

6. Select "MPI/GDI/DIESEL" from System select

Screen of the M.U.T.-III.

7. Select "Special Function" from MPI/GDI/DIESEL

Screen.

8. Select "Learning" from Special Function Screen.

9. Select "Battery current SNSR.calibration" from

Learning Screen.

10.Start the calibration by pressing the "OK" button.

11.Confirm that the M.U.T.-III data list item No. 119

<Low CO

2

specification, FFV> No. 452 <4N1>

Battery current sensor calibration is "Completed".

12.After the ignition switch is in "LOCK" (OFF)

position, disconnect the M.U.T.-III.

13.Install the battery current sensor.

FORCED LEARNING OF ESTIMATED

ETHANOL CONCENTRATION <FFV>

M1001018200048

PURPOSE

When carrying out the learning of the estimated etha-

nol concentration every time the engine starts or the

fuel is supplied, the Flexible Fuel Vehicle (FFV) con-

trols the injection amount according to the ethanol

concentration in the fuel tank. The difference, how-

ever, arises between the ethanol concentration

stored by the engine-ECU and the actual ethanol

concentration when performing the following driving

or work. This can possibly impact on the poor cold

engine starting or the drivability in the cold state.

Using the M.U.T.-III, this malfunction can be solved

by carrying out the forced learning of the estimated

ethanol concentration.

• Repeating the short distance run that cannot

switch to the estimating concentration mode.

• Replacing the fuel of the fuel tank

• Outputting the diagnosis code

• Replacing the fuel gauge unit and the fuel supply

line

• Replacing the engine-ECU