Mitsubishi Evolution X. Manual - part 858

MB991006

ON-VEHICLE SERVICE

TSB Revision

FRONT SUSPENSION

33-7

ON-VEHICLE SERVICE

FRONT WHEEL ALIGNMENT CHECK AND

ADJUSTMENT

M1332012400267

CAUTION

After performing the front wheel alignment, perform a cali-

bration for the ASC-ECU to learn the steering wheel sensor

neutral point. (Refer to GROUP 35C

− On-vehicle Service,

Steering Wheel Sensor Calibration

1. Before the wheel alignment measurement, maintain the

front suspension, the steering system, the wheel and tires in

good condition.

2. Park the vehicle on a level surface, and position the front

wheel in the straight-ahead position to measure the wheel

alignment.

TOE-IN

Standard value: 0

± 2 mm (0 ± 0.07 inch)

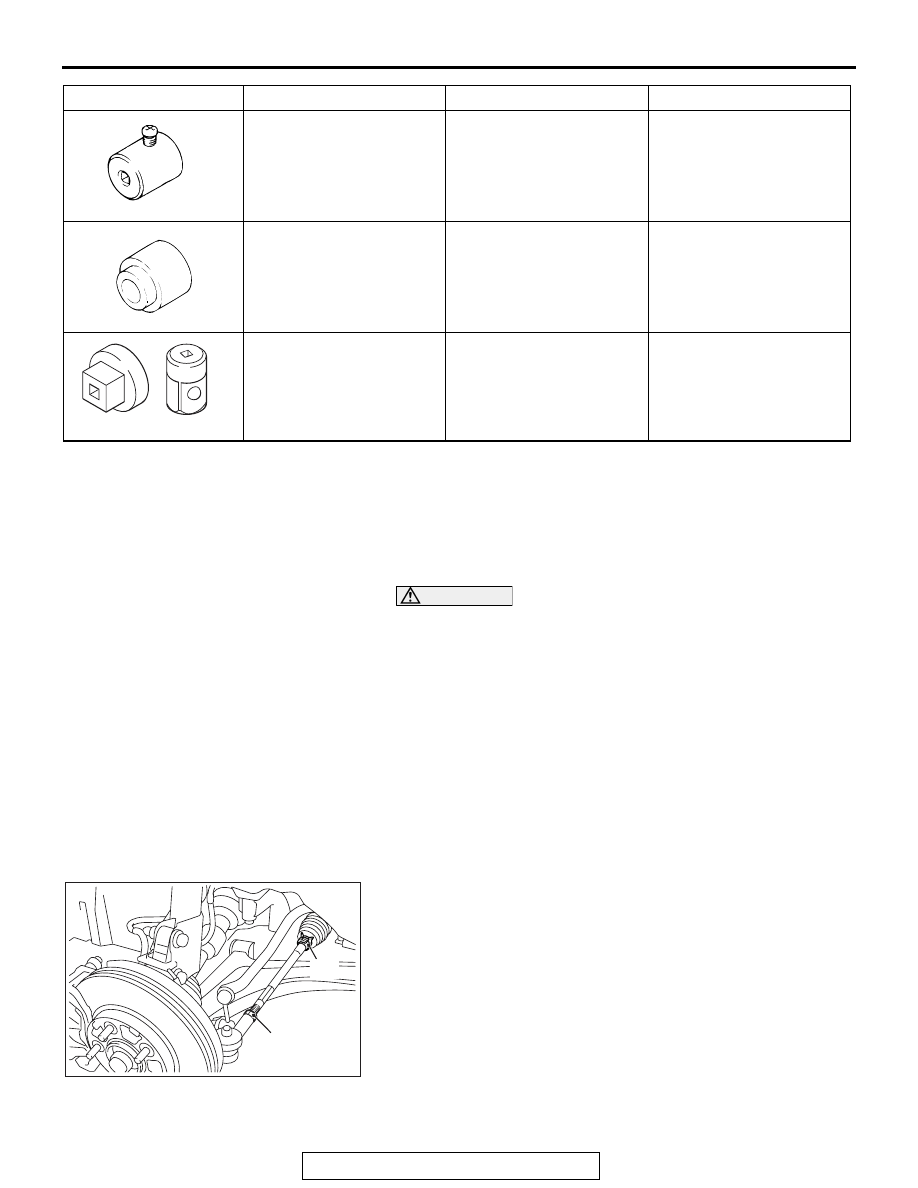

AC705438 AB

Clip

Lock nut

1. Loosen the lock nut with the tie-rod clip removed, and then

perform the adjustment by turning the tie-rod left/right at the

same degree in the opposite direction.

NOTE: The toe moves to the outside by turning the tie-rod

left to the forward direction, and right to the reverse direc-

tion.

2. After adjustment, check that the steering angle is within the

standard range using the turning radius gauge. (Refer to

GROUP 37

− On-vehicle Service

MB991006

Preload socket

MB990228-01

Lower arm ball joint

breakaway torque check

MB990800

MB990800

Ball joint dust cover

installer

MB990800-01or General

service tool

Lower arm ball joint dust

cover installation

MB990326

MB990326

Preload socket

General service tool

Ball joint turning torque

check

Tool

Tool number and name

Supersession

Appli8cation