Mitsubishi Evolution X. Manual - part 823

ON-VEHICLE SERVICE

TSB Revision

BASIC BRAKE SYSTEM

35A-19

3. Remove the following parts from the brake caliper assembly.

(1) Shim

(2) Brake pad assembly

CAUTION

Keep grease or other soiling off the pad and brake disk

friction surfaces.

AC706163AB

MB990520

Piston

Caliper

body

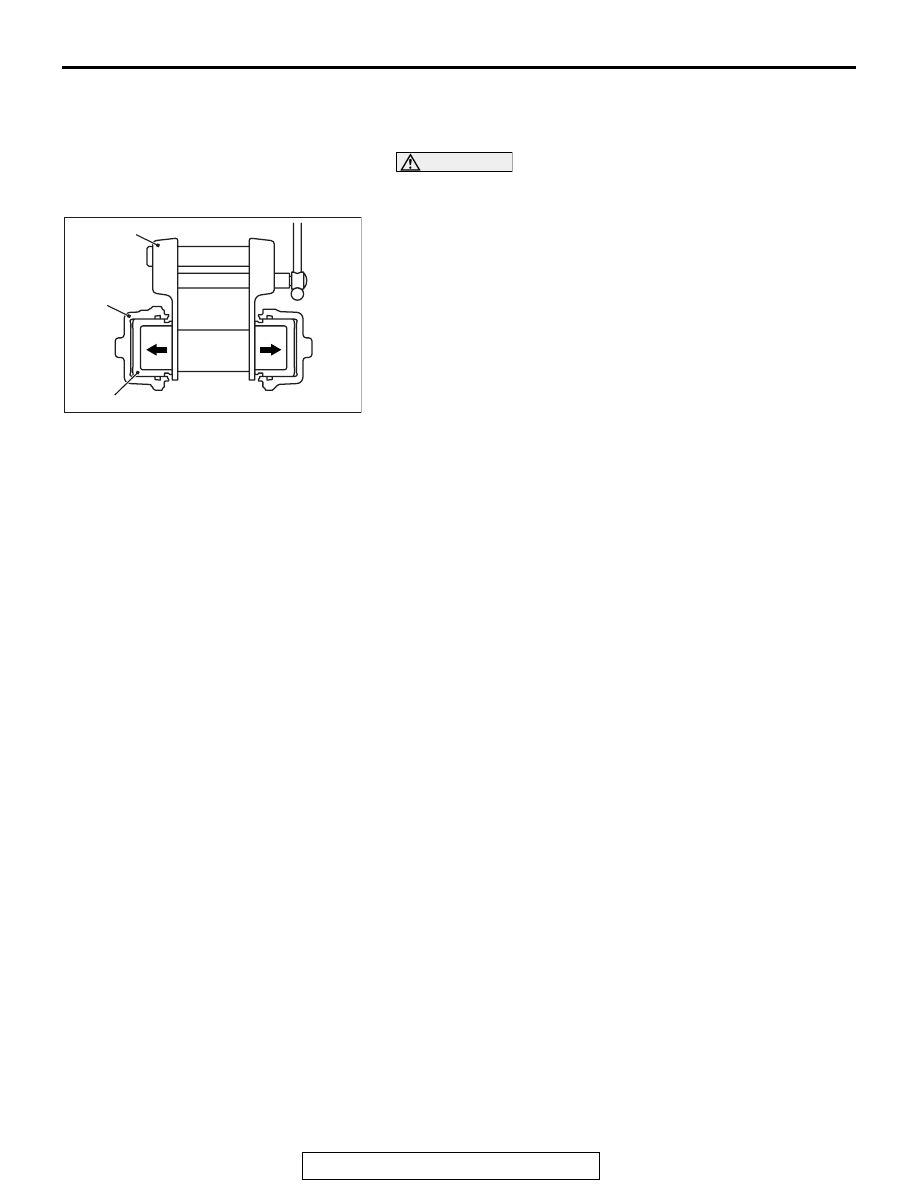

4. Clean the piston, then press the piston into the cylinder

using the piston expander (Special tool: MB990520).