Mitsubishi Evolution X. Manual - part 787

DIAGNOSIS

TSB Revision

ACTIVE SKID CONTROL SYSTEM (ASC)

35C-155

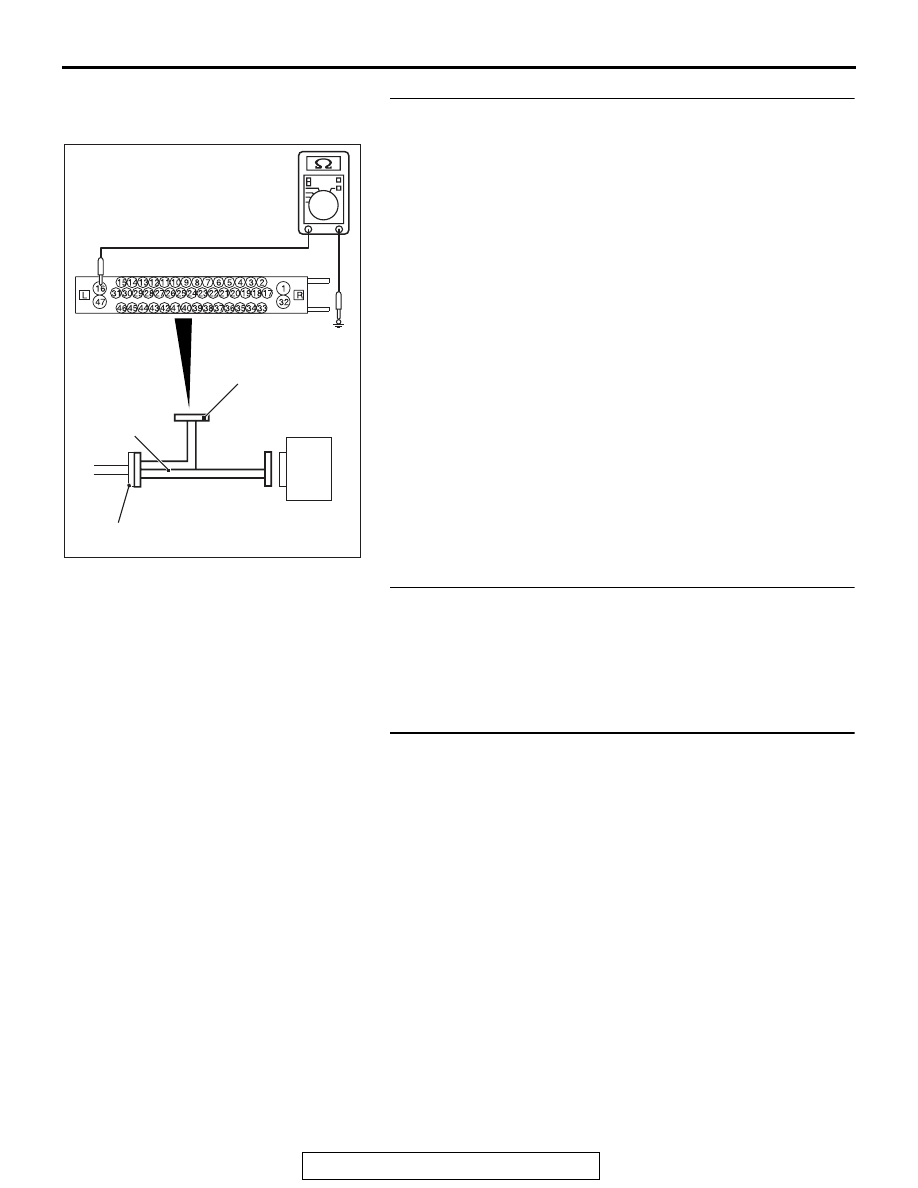

STEP 15. Resistance measurement at A-05 ASC-ECU

connector

(1) Disconnect the connector, connect the ABS check harness

(Special tool: MB991997) to the wiring harness-side

connector, and measure the voltage at the special tool

connector side.

NOTE: Do not connect the special tool to ASC-ECU.

(2) Measure the resistance between the terminal No. 16 and

the body ground as well as between the terminal No. 47

and the body ground.

OK: Continuity exists (2

Ω or less)

Q: Is the check result normal?

YES : Go to Step 16.

NO : Repair the wiring harness.

STEP 16. Check whether the DTC is reset.

Q: Is DTC C2101 set?

YES : Replace the hydraulic unit (incorporates in

.) Then go to Step 17.

NO : Intermittent malfunction. (Refer to GROUP 00

− How

to Cope with Intermittent Malfunction

.)

STEP 17. Check whether the DTC is reset.

Q: Is DTC C2101 set?

YES : Return to Step 1.

NO : The procedure is complete.

AC400817CO

ASC-ECU

MB991997

A-05 ASC-ECU

harness connector

Check harness