Mitsubishi Evolution X. Manual - part 431

DIAGNOSIS <TC-SST>

TSB Revision

TWIN CLUTCH- SPORTRONIC SHIFT TRANSMISSION (TC-SST)

22C-181

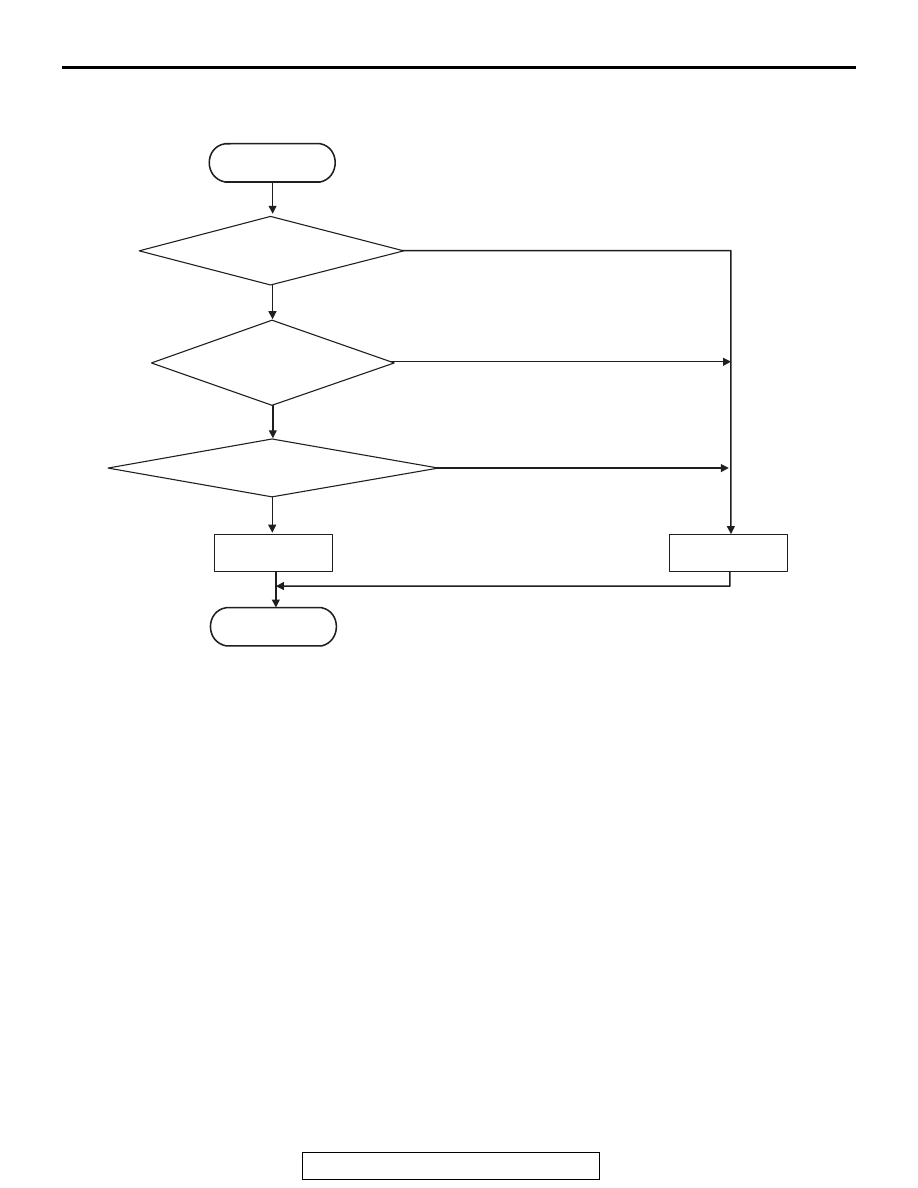

LOGIC FLOW CHARTS (Monitor Sequence)

<Functional check - move opposite direction left side>

.

DTC SET CONDITIONS <FUNCTIONAL

CHECK - MOVE OPPOSITE DIRECTION

LEFT SIDE>

Check Conditions

• Voltage of battery: 8 V or more.

• Voltage of battery: 16.5 V or less.

• Engine speed: 500 r/min or more.

• Time since above engine condition: 400 millisec-

ond or more.

• Shift fork 1 and 2 current gear: Neutral.

• Shift fork 1 and 2 target direction: 0 mm (0 inch)

or more.

JUDGMENT CRITERIA

• Shift fork 1 and 2 position: −1.8 mm (−0.071 inch)

or less. (250 millisecond)

.

OBD-II DRIVE CYCLE PATTERN

<FUNCTIONAL CHECK - MOVE

OPPOSITE DIRECTION LEFT SIDE>

The shift fork 1 and 2 positions remain

−1.8 mm

(

−0.071 inch) or more for 250 milliseconds.

.

PROBABLE CAUSES

• Malfunction of TC-SST-ECU

• Malfunction of TC-SST shift fork

AC710721

START

No

Good

Malfunction

END

Continuous failure

for 250 msec

No

Yes

Yes

Monitoring condition met

Yes

No

Shift fork position

< -1.8 mm (-0.071 inch)