Mitsubishi Evolution X. Manual - part 424

DIAGNOSIS <TC-SST>

TSB Revision

TWIN CLUTCH- SPORTRONIC SHIFT TRANSMISSION (TC-SST)

22C-153

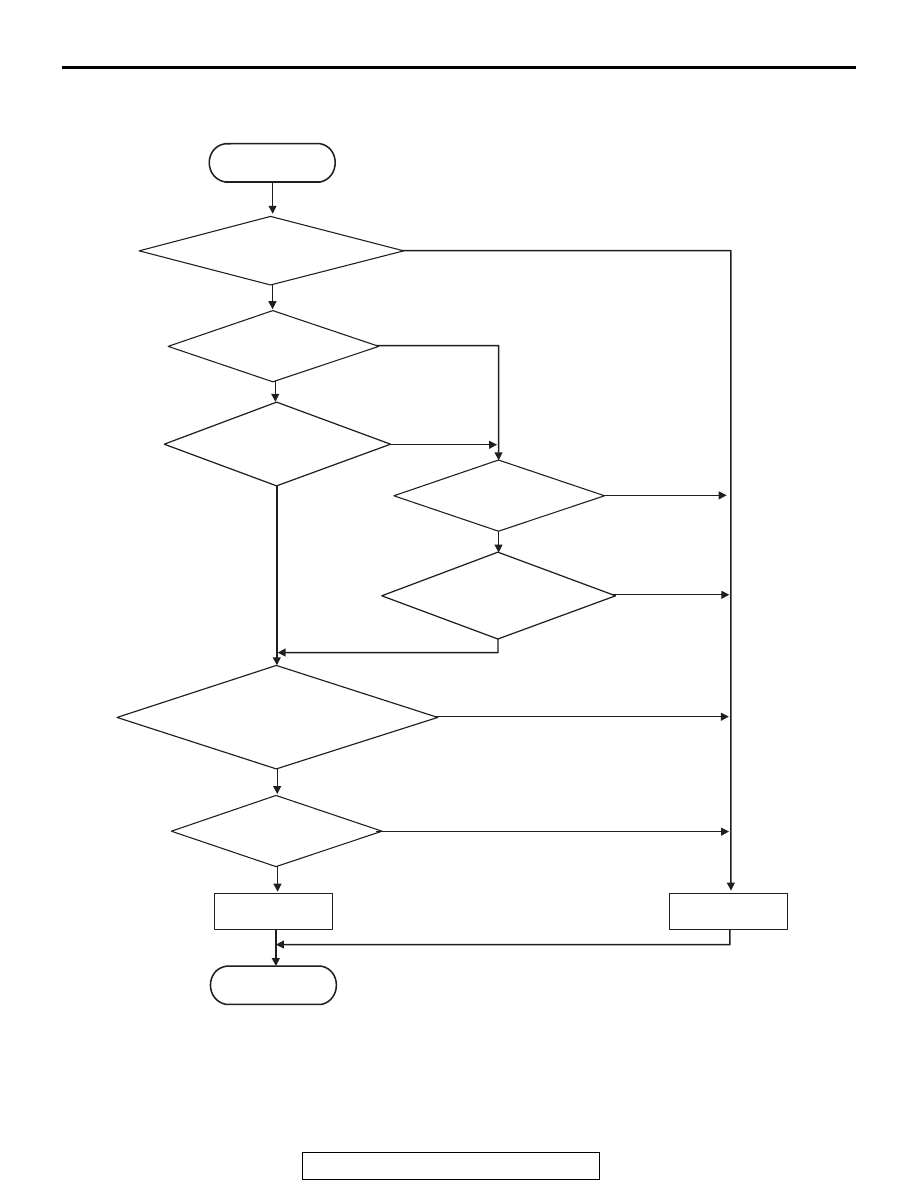

LOGIC FLOW CHARTS (Monitor Sequence)

<Functional check - Shift fork 1 requested but shift fork 3 movement>

.

AC710687

START

No

Good

Malfunction

END

No

Yes

Yes

Yes

No

No

Yes

Monitoring condition met

Yes

No

Yes

Shift fork 3 position

neutral position

No

Yes

No

|Initialized fork position -

shift fork 1 position| < 2.5 mm

(0.098 inch)

Shift fork 3 position

6th gear side

Shift fork 3 position

> -6 mm (-0.24 inch)

Continuous failure

for 200 msec

|Shift fork 3 position|

> 1.8 mm (0.071 inch)